The frames of the pillows and backs, hinged together, are made of durable metal frames. Wire springs are attached to the frames. To avoid creaking, the ends of the springs are covered with a layer of polyethylene. On the frames of the pillows and backs, soft stuffings made of foamed polyurethane foam are installed. The upholstery is made of artificial leather on a knitted basis (there may be cloth options) with a backing of synthetic wool, which, after dielectric welding, gives clear decorative reliefs.

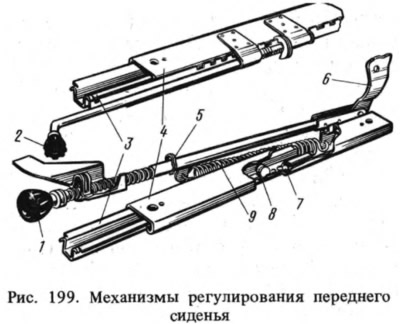

Seat sled (pic. 199) consist of guides 3 and sliders, which are stamped from sheet steel. The movement of the slider along the guide is carried out along two rollers 8. The displacement of the slider to the sides and upwards is eliminated by two pairs of steel balls 7 located in the channels between the walls of the slider and the guide with an interference of up to 0.3 mm.

The seat is fixed in the desired position by a latch, which, under the action of a spring, enters one of the grooves of the comb lock welded to the slide guide. The latch is released by handle 2 when it is pressed down.

The backrest tilt adjustment mechanism consists of a rod connected pivotally to the backrest reinforcement 6, a screw 1 with a plastic handle, a latch? and springs 9. The annular points of the screw 1 in the front engage with the teeth of the latch. When lifting the screw handle up (coarse backrest adjustment) the screw is disconnected from the teeth of the latch, the spring 9 moves the backrest forward or the driver presses it back. When turning the handle (fine adjustment) the screw is held in place by a retainer, and the rear threaded end of the screw moves the seatback through the rod. To prevent the screw from turning out completely, there is a groove on the threaded end of the screw, into which the cotter pin 5 is inserted.

Possible malfunctions of the control mechanism, their causes and remedies are given in Table. 35.