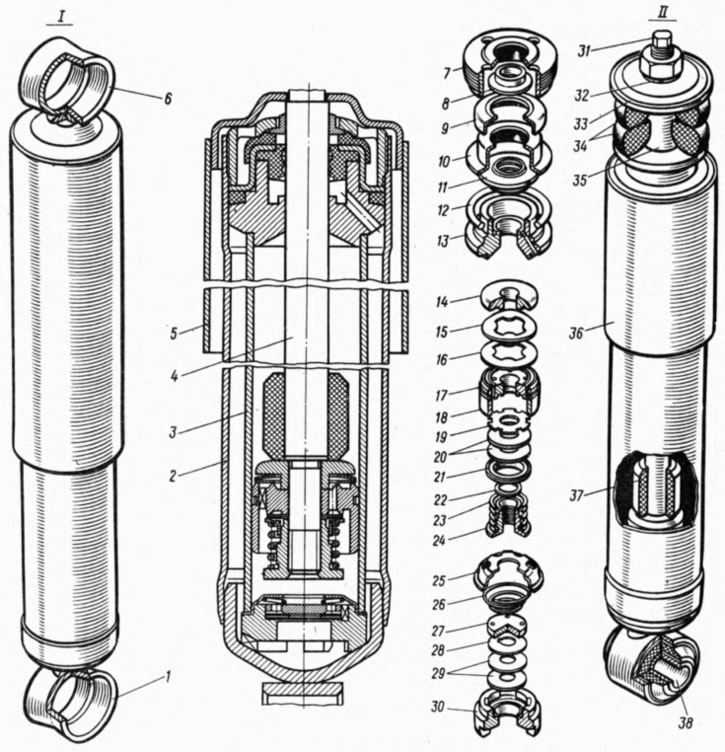

Pic. 122. Front and rear shock absorbers:

1 - lower eye; 2 - reservoir; 3 - cylinder; 4 - stock; 5, 36 - casing; 6 - the upper eye of the shock absorber; 7 - tank nut; 8 - protective ring of the rod; 9 - gasket of the protective ring of the rod; 10 - holder of the stuffing box; 11 - stem gland; 12 - tank sealing ring; 13 - rod guide sleeve; 14 - restrictive plate; 15 - bypass valve spring; 16 - bypass valve plate; 17 - piston ring; 18 - piston; 19 - throttle disc of the recoil valve; 20 - recoil valve disks; 21 - recoil valve plate; 22 - washer of the recoil valve nut; 23 - recoil valve spring; 24 - recoil valve nut; 25 - clip of the compression valve; 26 - compression valve spring; 27 - compression valve plate; 28 - throttle disc of the compression valve; 29 - compression valve discs; 30 - compression valve housing; 31 - nut for fastening the upper end of the front suspension shock absorber; 32 - spring washer; 33 - washer of the shock absorber mounting cushion; 34 - pillows; 35 - spacer sleeve; 37 - stock buffer; 38 - rubber-metal hinge.

Cylinder 3 shock absorber is located inside the tank 2. The annular space between them is filled with liquid. Inside the working cylinder there is a rod 4 with a piston 18. The piston has vertical channels located along two circles. The channels on a small circle are closed from below by disks and a recoil valve, and on a large one - from above by a plate 16 of the bypass valve.

A compression valve is installed at the bottom of the cylinder. In the ceramic-metal valve body 30, a seat is made, to which disks 28 and 29 are pressed by spring 26 through plate 27. Throttle disk 28 has a cutout through which fluid is throttled at low piston speed. To ensure the passage of fluid from reservoir 2 to cylinder 3 and back, a cylindrical groove and four vertical channels are made in the lower part of the compression valve body, and in cage 25 there are six side and one central holes.

From above, a guide bushing 13 is installed in the cylinder, which is sealed in the tank with a ring 12, and the rod outlet is sealed with an gland 11 with a clip 10. All parts located in the upper part of the cylinder are pressed with a nut 7.

During compression, the liquid under the pressure of the piston, overcoming the resistance of the flat spring 15 of the bypass valve, flows from the under-piston space to the over-piston space. All the displaced liquid cannot pass in this way, since the pushed-in rod occupies part of the volume released by the piston, therefore, the other part of the liquid, bending the inner edges of the disks 29, flows from the cylinder into the reservoir. With a smooth stroke of the rod, the force from the fluid pressure will be insufficient to press the inner edges of the disks 29 from the plate, and the liquid will pass into the tank through the cutout of the throttle disk 28.

During the return stroke, pressure is created above the piston 18, and a vacuum is created under the piston. The fluid from the over-piston space, overcoming the resistance of the spring 23, bends the outer edges of the recoil valve disks 20 and flows into the lower part of the cylinder. In addition, due to rarefaction, part of the liquid from the reservoir, bending the outer edges of the disks 29 of the compression valve, fills the lower part of the cylinder.

At a low piston speed, when the fluid pressure is insufficient to squeeze the recoil valve discs, the fluid will be throttled through the side cutouts of the throttle disc, creating resistance to the recoil stroke.