Checking the generator on the car

If the battery charge control lamp is on when the engine is running, then the generator is roughly determined as follows:

- slightly pulling out the carburetor air damper control knob, bring the idle speed of the crankshaft to 1000-1500 rpm;

- briefly disconnect the wire from the output "—" battery. If the engine stops, this indicates that the generator is faulty and all consumers are powered by the battery.

Checking the generator on the stand

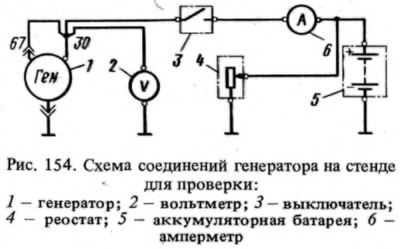

Checking the generator on the stand allows you to determine the serviceability of the generator and the compliance of its characteristics with the nominal ones. The connection diagram for checking the generator is shown in fig. 154. At the tested generator, the brushes must be well ground to the slip rings of the collector, and the rings themselves must be clean.

The electric motor of the stand is turned on, the voltage at the generator output is set to 14 V with a rheostat 4 and the rotor speed is adjusted to 5000 rpm. Let the generator run in this mode for at least 2 minutes, and then measure the recoil current. For a working generator, it must be at least 44 A.

If the measured value of the output current is less, then this indicates a malfunction in the stator and rotor windings, damage to the valves or wear of slip rings and brushes. In this case, a thorough inspection of the windings and valves is necessary to determine the location of the fault.

If you suspect a malfunction of the rectifier valves, check the recoil current on the warm generator. Such a check allows you to better identify the malfunction of the valves by a sharp decrease in the recoil current with an increase in the temperature of the generator. To warm up, it is necessary to let the generator run for at least 15 minutes at a rotor speed of 5000 rpm and a voltage of 14 V at the generator output. Then the recoil current is measured, which on a warm generator should be at least 42 A.

Checking the generator with an electronic oscilloscope

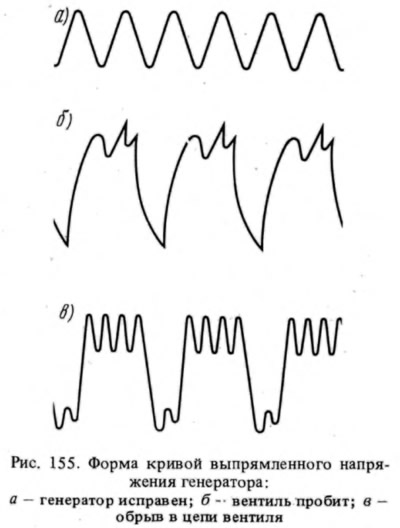

The oscilloscope allows you to accurately and quickly check the health of the generator and determine the nature of the damage by the shape of the rectified voltage curve. To check, set the generator rotor speed to 1500-2000 rpm, feeding the excitation winding of the generator from the battery, but from the clamp "30" the battery is turned off. With serviceable valves and stator winding, the rectified voltage curve has a sawtooth shape with uniform teeth (pic. 155, a). If there is a violation of the connections in the stator winding or an open or short circuit in the valves, the shape of the curve changes dramatically: the uniformity of the teeth is disturbed and deep cavities appear.

Checking the excitation winding of the rotor. The health of the winding and the reliability of the fit of the brushes to the slip rings can be checked on the stand without disassembling the generator by measuring the resistance between the plug "67" and generator housing. If the winding does not have short-circuited turns and the brushes are well ground to the slip rings, then the resistance should be 4.4+0,3-0,2 Ohm at 20°C.

After disassembling the generator, check the resistance of the field winding between the two slip rings, which should be (4,3±0,2) Ohm at 20°C. In this case, it is necessary to monitor the reliability of contact between the rotor rings and the conductors attached to them.

Stator check

The stator is checked separately after disassembling the generator. Its winding leads must be disconnected from the rectifier valves. First of all, they check with an ohmmeter or with the help of a test lamp and a battery, whether there are breaks in the stator winding and whether its turns close to the housing. The insulation of the winding wires must be free from overheating, which occurs during a short circuit in the rectifier valves. A stator with such a damaged winding should be replaced. Then they check with a special flaw detector whether there are short-circuited turns in the stator winding.

Checking the rectifier valves

A good valve only allows current to flow in one direction, a bad valve may not allow current to flow at all (open circuit) or pass current in both directions (short circuit).

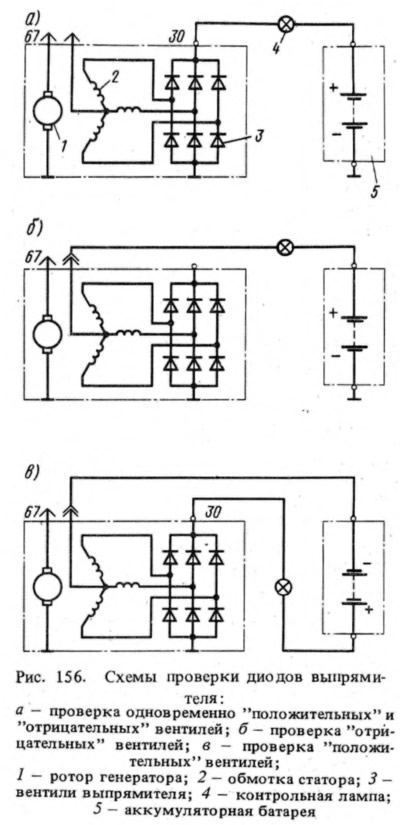

A short circuit in the valves can be checked without removing the alternator from the vehicle by first disconnecting the wires from the battery and the alternator. You can check with an ohmmeter or with a lamp (25-40W) and battery as shown in Fig. 156.

First, check if there is a short circuit at the same time in the positive and negative valves. For this "+" batteries through the lamp are connected to the clamp "30" generator, and "—" batteries - to the generator housing (pic. 156 and). If the lamp is on, both the negative and positive valves are shorted.

You can test for a short in the negative valves by connecting "+" batteries through a lamp with a plug of the neutral wire of the stator winding, and "—" batteries - with generator housing (pic. 156b). A lamp on indicates a short circuit in one or more of the negative valves. It should be remembered that in this case, the burning of the lamp may be due to the short circuit of the turns of the stator winding on the generator housing. However, such a malfunction is less common than a short circuit of the valves.

To check for short circuits in positive valves "+" batteries through the lamp are connected to the clamp "30" generator, and "—" batteries with stator zero point output plug (pic. 156, in). A burning lamp will indicate a short circuit in one or more of the positive valves.

Without disassembling the generator, a break in the valves can only be detected indirectly when checking the generator on the stand for a significant reduction (by 20-30%) the strength of the given current compared to the nominal. If the generator windings are in good order, and there is no short circuit in the valves, then the reason for the decrease in the output current is an open in the valves.