Rules for testing and operation

In order not to damage the regulator during inspection and operation, the following rules must be observed.

Do not mix up the wires connected to the plugs "15" And "67" (see fig. 159). If the wires are inadvertently mixed up, the regulator will not work and the upper contacts will be permanently closed. The voltage at the output of the generator increases greatly, which will lead to rapid boiling and splashing of the electrolyte from the battery, as well as damage to consumers by increased voltage. In addition, sintering of the upper contacts will occur and the voltage regulator will have to be replaced.

Do not connect RFI capacitors to the circuit between the plugs "67" regulator and generator. This violates the working conditions of the contacts, and they are quickly damaged.

Do not connect additional consumers of electricity to the power supply circuit of the excitation winding of the generator, as this will greatly increase the voltage of the generator.

It is forbidden to check the functionality of the regulator by short-circuiting its plugs "15" And "67". In this case, the generator voltage increases and the rectifier may be damaged.

It is not recommended to unnecessarily remove the cover of the regulator, so as not to violate the tightness of the seal. The ingress of moisture and dust under the cover leads to contamination, burning of the contacts and, consequently, disruption of the normal operation of the regulator. Therefore, all materials used in the regulator are tested for the absence of outgassing. If it is necessary to replace the gasket, the new gasket should only be made of polyurethane, provided for by the design of the regulator.

The regulator should be kept clean and protected from accidental impacts that could affect its adjustment. It is also necessary to monitor the reliability of the connection of the regulator housing to the ground through the mounting screws, since a poor connection increases the generator voltage above normal.

Testing and adjustment on the stand

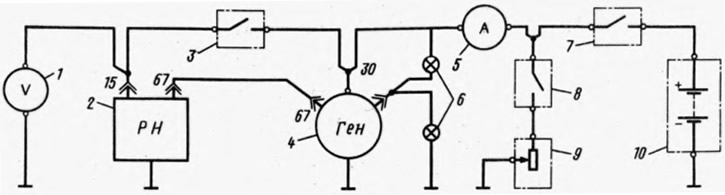

The regulator is checked and adjusted on a stand that has a generator, battery, thermostat and electric motor with adjustable speed over a wide range (pic. 160). The regulator with a closed lid is installed on the stand with the plugs down.

Pic. 160. Scheme for testing the voltage regulator on the stand:

1 - voltmeter with a scale of 15 V, accuracy class not lower than 0.5; 2 - voltage regulator; 3 - main switch; 4 - generator; 5 - ammeter with a scale up to 50 A; pilot lamps 3 W, 12 V; 7 - battery switch; 8 - rheostat switch; 9 - rheostat 5-30 A,

15 V; 10- battery

Particular attention must be paid to the reliability of the wire connection so that their resistance is minimal. It is necessary that the wires from switch 3 are connected directly to the clamp "30" generator and plug "15" regulator, and the regulator housing was connected directly to the generator housing. All connecting wires should be as short as possible. If tray wiring is used at the stand, the trays must be made of non-magnetic material.

During control checks on the stand, the regulator should not be allowed to operate with the battery disconnected, as this may damage the regulator contacts.

Light bulbs 6 control the health of the generator and, if it is working, should have the same glow.

Before checking, the regulator is heated in a thermostat for 15-18 minutes at (50±3) °C, feeding the regulator winding with current at a voltage of 12-13 V. The voltage is set by a rheostat 9 with the switches 3 on, and the generator not running.

Immediately after warming up, check and adjust. When checking and adjusting both the 1st and 2nd stages, make sure that the voltage was stable, i.e. did not fluctuate sharply.

2nd stage control. The generator rotor is set in rotation and brought to 5000 rpm. The rheostat sets the generator load current to 2-12 A. Check the generator voltage, which should be (14,2±0,3) C. If it differs, stop the generator, disconnect the battery, remove the cover from the regulator and, bending the bracket 12 (see fig. 159), weaken, if the voltage is increased, or increase, if the voltage is low, the tension of the spring 11. Then the regulator cover is replaced and the voltage of the 2nd stage is checked again.

After the end of the check and adjustment of the 2nd stage, the 1st stage is immediately checked.

1st stage control. At a rotor speed of 5000 rpm, rheostat 9 sets the load current to 25-35 A. In this case, the voltage should be no more than 0.7 V lower than the value obtained by adjusting the 2nd stage.

If the voltage does not fall within these limits, then stop the generator, turn off the battery, remove the cover of the generator, loosen the nut 6 (Withm. fig. 159) and move the rack 8 by 0.1-0.2 mm.

When the voltage is increased, the rack is shifted down, and if it is low, it is moved up. At the same time shift the rack 7 to maintain the gap (0,45±0,1) mm between 2nd stage contacts. During this operation, it is necessary to monitor the contacts of the 1st and 2nd stages. The armature contact must not extend beyond the contacts on the uprights.

Tighten the nut 6, replace the cover, check the regulator again (both 1st and 2nd stage) and, if necessary, repeat the operations until fine adjustment is obtained.

After adjustment is complete, the regulator cap is cleaned and placed on the hot regulator to minimize moisture absorption.