Disassembly

Having unscrewed the fastening screws, remove the brush holder 2 (pic. 157) with brushes. Unscrew the nuts of the coupling bolts 14 and remove the cover 11 of the generator together with the rotor. The rotor is clamped in a vice, the pulley fastening nut is unscrewed and the pulley is removed from the rotor shaft with a puller 02.7823.9504. The segment key is removed from the groove on the shaft and the cover is removed. The nuts of the screws connecting the valve tips to the stator winding terminals are unscrewed, the neutral wire plug is removed from the block 4 and the stator 8 is removed from the cover 16 of the generator. Unscrew the nut of the contact bolt 7 and remove the rectifier unit 6 (or radiator with positive valves).

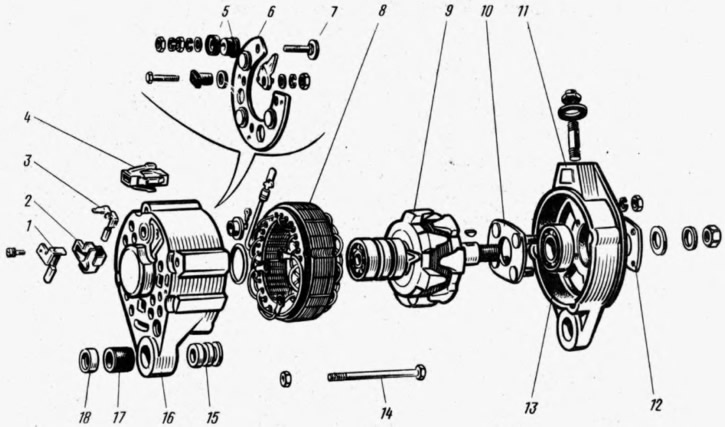

Pic. 157. Generator details:

1 - "negative" brush; 2 - brush holder; 3 - ''positive" brush; 4 - block of the neutral wire plug; 5 - insulating bushings of the contact bolt; 6 - radiator with "positive" valves; 7 - contact bolt; 8 - stator; 9 - rotor; 10 - inner washer for fastening the bearing; 11 - cover on the drive side; 12 - outer washer for fastening the bearing; rotor bearing; 14 - coupling bolt; 15 - clamping sleeve; 16 - cover from the side of slip rings; 17 - buffer sleeve; 18 - bushing.

Assembly

Assemble the generator in the reverse order of disassembly. The misalignment of the holes in the paws of the generator covers should be no more than 0.4 mm. Therefore, during assembly, it is necessary to insert a special gauge into these holes. The convex side of the pulley spring washer must be in contact with the nut. Tighten the pulley nut with a torque of 4.5-7.2 kgf·m.

Brush holder replacement

If the brushes are worn out and protrude from the brush holder by less than 5 mm, then replace the brush holder with brushes. Before installing the brush holder, blow out the place (no text) rubbing oil mixed with coal dust.

Replacing the rotor bearing on the drive side

To remove the defective bearing from the cover, it is necessary to unscrew the nuts of the screws that tighten the bearing fastening washers, remove the washers with screws and press the bearing out on a hand press. If the nuts do not loosen (the ends of the screws are punched), then cut off the ends of the screws. It is only possible to install a new bearing in the generator cover if the bearing hole is not deformed. The hole diameter should be 41.967-41.992 mm. If the hole is oversized or deformed, replace the cover with a new one.

The bearing is pressed into the cover on a press and then clamped between two washers tightened with screws and nuts. After tightening the nuts, the ends of the screws should be punched out.

Valve replacement

If a rectifier unit is installed on the generator, then in the event of a breakdown, the rectifier unit is replaced. If the valves are located in the cover 16 and the radiator, then it is possible to change the negative valves pressed into the cover. Positive valves pressed into the radiator must not be changed. If one or more positive valves are damaged, replace the radiator together with the valves.

The defective negative valve is carefully pressed out on the press. You can not knock it out with a hammer, so as not to spoil the hole for the valve and not damage other serviceable valves pressed into the cover.

The new valve is carefully, without distortion, pressed into the cover also on a press using a punch A.76028 and support A.76031. It is strictly forbidden to press the valve with hammer blows. The pressing force must act on the valve body as shown in fig. 158 arrows. The valves are pressed into the generator cover until the flange stops. For valves with a non-knurled collar near the flange, a gap of 0.1-1 mm is allowed between the valve flange and the cover surface.