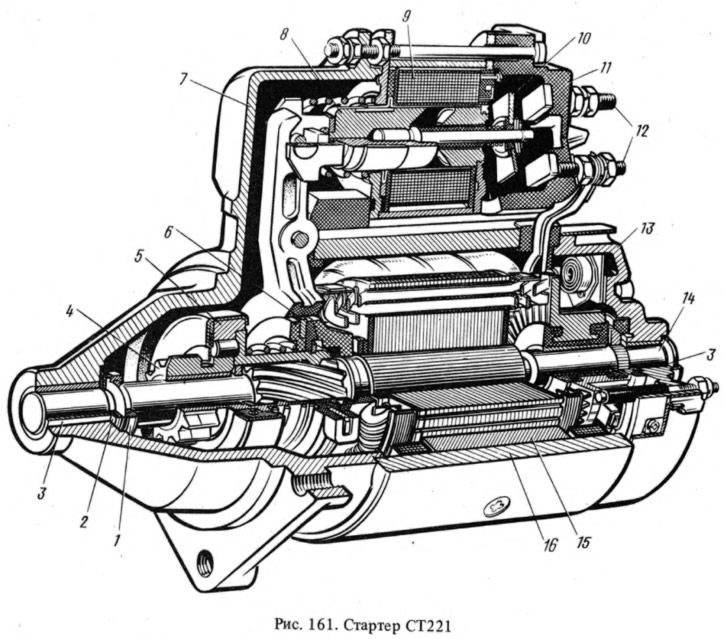

The covers and the starter housing are pulled together with pins that are screwed into the cover 7 and insulated with plastic tubes. In case 16, four poles 15 are installed - two with serial windings connected in series with the armature, and two with shunt windings (coils), connected in parallel.

Anchor 14 of the starter consists of a shaft, a core with a winding and a collector. The core is made of plates of electrical steel, pressed onto the middle part of the shaft, and has semi-closed grooves, in which the armature winding is laid. The collector consists of a plastic base reinforced with two steel rings, on which copper plates isolated from each other - collector lamellas are installed.

The armature shaft rotates in two porous ceramic-metal bushings 3 pressed into the starter covers and soaked in oil. The axial free play of the armature shaft is regulated by the selection of washers 2 and should be in the range of 0.07-0.7 mm.

At the front end of the armature shaft, a starter drive is installed, consisting of a freewheel roller clutch 5 and gear 1. Plastic disks are installed on the clutch hub - centering with a driving steel ring 6 and restrictive. They are pressed by a spring to the retaining ring on the hub. The hub has internal screw splines on one side and can, by turning, move along the screw splines of the armature shaft. On the other hand, an oil-impregnated ceramic-metal insert is pressed into the hub, sliding along the smooth part of the shaft. The gear has a brass bushing with graphite inclusions.

In the cover 13, 4 brush holders with copper-graphite brushes are riveted. Two brush holders are isolated from the cover by plastic plates. These are brush holders for positive brushes. The conclusions of the serial stator coils are attached to them. The other two brush holders are attached directly to the cover and are therefore connected to "weight". One of them is connected to the output of the shunt coils. The brushes are pressed against the commutator by helical springs.

A starter traction relay is attached to cover 7, consisting of an armature 8, a winding 9, a contact plate 10 and a cover 11 with contact bolts 12. The traction relay turns on the starter and engages gear 4 with the flywheel crown.

The dimensions of the relay and drive parts are selected so that the relay contacts close when the gear is only partially engaged with the flywheel crown. The starter armature starts to rotate, the clutch hub is screwed off the splines of the armature shaft and the gear is sent all the way into ring 1, fully engaging with the flywheel,

Since 1983, ST221 starters have been using a traction relay with two windings - retracting and holding. When the starter is turned on, both windings work first. And after the contacts of the traction relay are closed, the retracting winding is turned off, and the relay armature is held in the on position by one holding winding.

Since 1986, a starter 25.37.08 has been installed on cars, which has an end collector, as well as three serial stator windings and one shunt winding. The end manifold is made in the form of a plastic disk with copper plates embedded in it. Otherwise, the design of the starter 35.3708 is the same as that of the ST221 starter. The traction relay is two-winding.

Technical characteristics of the starter:

Rated power, kW - 1.3

Current consumption, A, not more than:

- at maximum power - 260

- in the inhibited state - 500

- at idle: ST221 - 35