The wheels of modern cars must be balanced without fail, and if it's not about balancing, then the cause of the beating is play in the hub bearing.

The design provides that tapered roller bearings 1 (see fig. 39) hubs 11 wore evenly. This is achieved by gradually turning the inner rings and using high-quality Litol-24 lubricant. However, time takes its toll or some subjective factors act, but backlashes arise.

Usually, the backlash in the bearings is checked by touch, shaking the hung wheel with both hands. At the same time, the car is securely fixed with a parking brake and wheel chocks. The wheel under test is lifted with a jack and, holding the top and bottom of the wheel with their hands, they try to rock it. With normal adjustment, the play should practically not be felt, although it exists, but very slight.

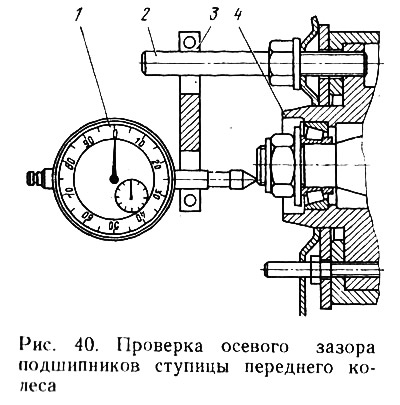

However, only a fairly experienced person can accurately determine the need for adjustment in this way. For an objective assessment, it is advisable to use a simple device (pic. 40), which is easy to make.

After removing the wheel, with a specially made bolt 2, fixture 3 is fixed on the wheel hub. The indicator leg 1 rests against the end of the wheel axle. The indicator needle should be in the zero position. When you try to move the hub 4 along the axis to yourself determine the reaction of the indicator arrows. If the gap exceeds 0.15 mm, adjustment is necessary.

Eliminate backlash by tightening the bearing with a special nut 8 (see fig. 39), which, having a different direction of rotation for the right and left sides of the car, is also disposable. The operation is quite delicate and responsible, since by tightening the nut with more force than necessary, you can break the bearing. If you don’t make it, there will be a backlash, which means the beating of the wheel and its intense wear.

To adjust the hub bearing clearances, you need: a 27 mm wrench, a 17x19 mm spanner, a hammer, a chisel, a mounting blade, a jack, wheel stops, new nuts and Litol-24 grease.

With a clearly palpable backlash, perform the following operations:

- remove the wheel cap, unscrew the four bolts 10 (see fig. 39), remove the wheel and cap 9 of hub 11;

- unscrew nut 8 and replace it with a new one. In this case, it is useful to simultaneously rotate the hub in different directions, which will ensure self-alignment of the bearing rollers;

- on the bearing washer, mark the position of the middle of any face of the nut, turn it until the edge of the nut coincides with the mark on the washer, which will correspond to a turn of 30°;

- using a chisel and hammer, carefully loosen the nut and check again how the hub rotates;

- fill cap 9 with Litol-24 grease and install it in place. After setting the wheel cap, the operation is considered completed.

Over 20-25 thousand km, even the best lubricant loses some of its qualities, and the time comes when it needs to be changed to a new one. To perform this operation, you should securely fix the car, set the stops under the wheels using a jack, remove the wheel and hub cap 9. Having unscrewed the bolts, remove the caliper. Without disconnecting the brake hose, remove the hub, for which they unscrew the nut and remove the washer of the outer bearing. The hub is washed in kerosene with a brush, the seals of the internal bearings are replaced 1 (it is recommended by the factory) and fill with fresh Litol. The prepared hub can be installed in place and the necessary adjustment of the bearing can be provided with a nut.