We are talking about measures aimed at facilitating the subsequent operation, maintenance and current repair of the car, increasing its anti-corrosion resistance and protecting against encroachments on the safety of your car.

Threaded connections are tightened at the factory quite conscientiously and, as a rule, do not need additional tightening. We recommend checking only the tightness of the four nuts securing the exhaust pipe of the muffler to the exhaust manifold, and the bolts securing the gearbox to the rear axle beam. The intake pipe mounting nuts must be tightened smoothly, without jerking, to avoid breaking the studs.

On some cars, the spark plugs, the fixing nut of the chain tensioner, the fittings for pumping the wheel cylinders of the brakes and the clutch release cylinder, as well as the nuts of the valve adjusting bolts, are excessively tightened. As a result, these screwed connections cannot be unscrewed using the tools supplied with the vehicle, which can make it difficult for you to do future maintenance and troubleshooting yourself (for example, if necessary, replace a failed spark plug). Therefore, try to unscrew these screw connections and in case of failure at the first visit to the service station (and to maintain the right to warranty repairs, you must undergo service there after the first 2 thousand and 10 thousand kilometers of your car) ask the station worker to do it (tighten the connections after loosening them with the tool supplied with the car).

The car has a number of connections that will inevitably have to be disassembled during operation; If the necessary measures are not taken from the very beginning, it can be very difficult to do this due to corrosion. Therefore, we recommend:

- remove the disc brake pads of the front wheels, sand the fingers, wipe them and lubricate them with brake fluid before installation - this will facilitate the subsequent replacement of the brake pads;

- remove the brake drums of the rear wheels and lubricate with a thin layer of LITSSHa-24 their seating surfaces in contact with the stockings of the rear axle axle shafts;

- disassemble a number of threaded connections and lubricate the bolts before assembly (screws) LITOL-24. These connections include the studs of the lower mounts of the front shock absorbers, the mounts of the optical elements of the headlights, the lenses of the sidelights, the front direction indicators;

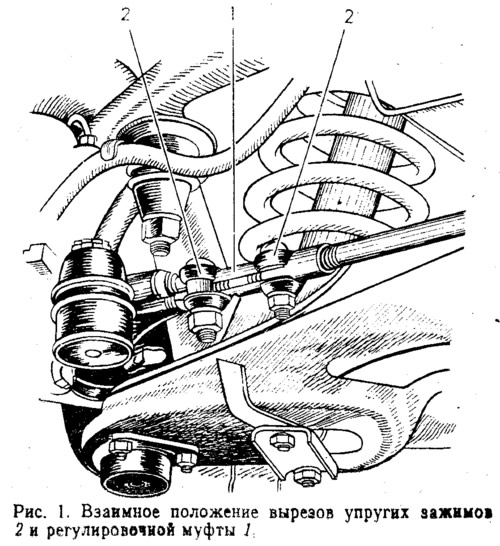

- check the position of the cutouts of the elastic clamps 2 (pic. 1), fixing the adjusting clutches 1 of the left and right side steering rods relative to the slots of the adjusting clutches. If the notches of the clamps and the slots in the couplings do not match, loosen the clamp pinch bolts and turn them until they line up with the slot; then re-tighten the bolts, but do not allow the ends of the clamps to touch after tightening. This operation must be done to ensure reliable clamping of the tie rod ends with the adjusting clutches.

Remove the wire ends from the battery terminals and put on the terminals the rings cut out of felt and soaked in engine oil (before installing the tips, wipe the terminals with a rag slightly moistened with gasoline). Such rings will protect the battery terminals from oxidation.

Keep a diary of your car. To do this, you can use an enlarged notebook, which, together with a pencil enclosed in it, is most conveniently stored in a glove box. In the diary, briefly but systematically record all maintenance and repair work performed, as well as the amount of gasoline poured into the tank. Before each entry, indicate the date and speedometer readings.

Equip your new vehicle with front and rear mudguards immediately, which will reduce corrosion and contamination of the relevant parts of the body. Install a skid plate under the sump to prevent engine damage due to the sump hitting hard objects.

Cars «Zhiguli» in general, they are satisfactorily protected from corrosion; so, the bottom of the car, the floor of the passenger compartment, the doors resist it quite well. Most vulnerable to corrosion:

- front fenders at the junction with the rear wall of the front wheel arch and opposite the cavity behind this wall;

- front panel between headlights and sidelights; longitudinal box spars of the base of the body («sills»);

- inner surfaces of the front fenders and rear wheel arches.

To enhance the anti-corrosion resistance, it is useful to cover the front panel between the headlights and sidelights with an additional layer of protective mastic (from the inside), inner surfaces of the front fenders (special attention should be paid to the junction of the wings with the rear wall of the front wheel arch) and inner surfaces of the rear wheel arches.

It is useful to squirt oil into the cavities under the back of the front wings once or twice a year. It is advisable to place oiled rags in the gap between the upper edge of the rear wall of the front wheel arch and the inner surface of the wing. Oil should be poured into the box-shaped spars of the body base once or twice a year.

The presence of a steering lock combined with precision numbered keys makes it difficult for your car to be stolen (unless, of course, you have developed the habit of turning the key to the desired position when leaving), However, it is desirable to equip the doors with an audible alarm to prevent unauthorized persons from entering the passenger compartment. The same is useful to do with the engine hood and trunk. It is useful to additionally fix wheel caps, as well as a spare wheel, with some special devices. The same applies to the radiator grille (except for the VAZ-2103 model, in which it can be removed only by opening the hood). It is better to replace the standard fuel tank cap with a special one with a lock built into it. It is better to remove the outside rear-view mirror at night, for which it is useful to equip it with a special detachable bracket.