Open large image in new tab »

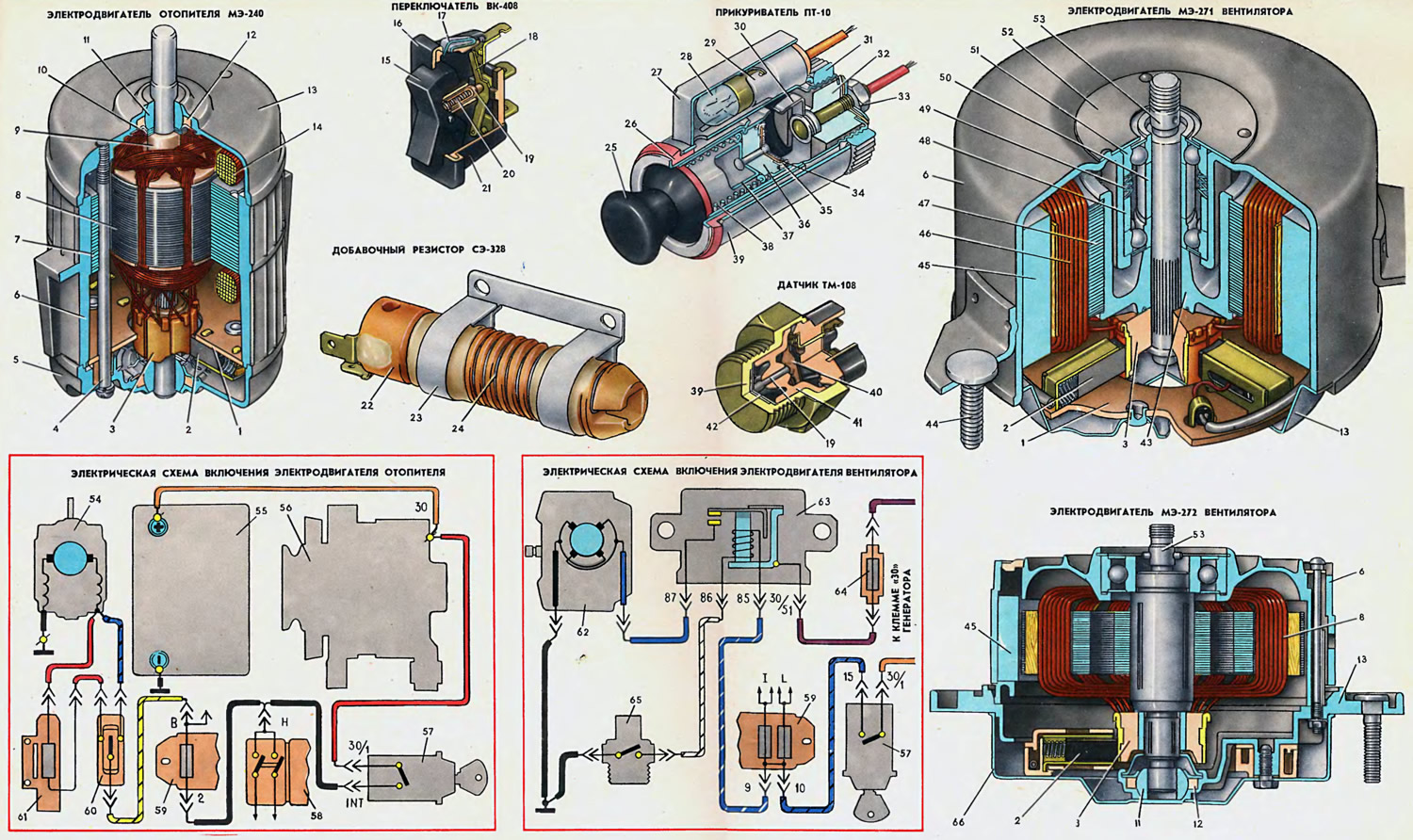

1. Traverse. 2. Brush. 3. Collector. 4. Coupling bolt. 5. Bottom cover. 6. Body. 7. Stator core. 8. Anchor. 9. Bushing of the armature shaft. 10. Adjusting washer. 11. Insert. 12. Felt washer. 13. Cover. 14. Stator winding. 15. Key. 16. Frame. 17. Spring holder. 18. Moving contact. 19. Pusher. 20. Pusher spring. 21. Corps. 22. Corps. 23. Resistor mounting bracket. 24. Nichrome wire. 25. Handle. 26. Diffusing rim. 27. Cap. 28. Lamp A12-4. 29. Lamp holder. 30. Bimetallic bracket. 31. Cigarette lighter fastening nut. 32. Bimetallic clip insulator. 33. Nut of fastening of a bimetallic bracket. 34. Heating element. 35. Cup. 36. Heating element insulator. 37. Inner glass. 38. Spring. 39. Corps. 40. Mobile contact plate. 41. Pusher guide. 42. Bimetallic washer. 43. Anchor core hub. 44. Motor mounting bolt. 45. Stator pole (permanent magnet). 46. Anchor winding. 47. Anchor core. 48. Outer spacer. 49. Belleville spring washers. 50. Internal spacer. 51. Ball bearing. 52. Bearing cover. 53. Anchor shaft. 54. Heater motor. 55. Battery. 56. Generator. 57. Ignition switch. 58. Block of switches. 59. Fuse box. 60. Heater motor switch. 61. Additional resistor. 62. Fan motor. 63. Relay for turning on the fan motor. 64. Motor fuse. 65. Fan motor sensor. 66. Casing.

Heater motor

Technical specifications:

- Rated voltage, V - 12

- Rated power, W - 20

- Frequency of rotation of the armature shaft with an impeller at rated power, rpm - 3000

- Consumed current at rated power, A - 6 (4,5*)

- Low frequency of rotation of the armature shaft with the impeller, rpm. — 2200

- Current consumption at 2200 rpm armature shaft, A - 4.5 (2,7*)

* For electric motor ME-255.

In the car heater «Zhiguli» an electric motor of the ME-240 or ME-255 type is used. The electric motor ME-255 is unified with the electric motor ME-241 of the wiper and therefore is not described here. The ME-240 electric motor is a two-pole two-brush DC electric motor with series excitation. The electric motor has two rotation speeds: 3000 and 2200 rpm. A lower speed is provided by the inclusion of an additional resistor SE-328 in its power circuit.

The electric motor consists of a housing 6, two covers 5 and 13 and an armature 8. In the housing, cast from an aluminum alloy, the stator core 7, made of steel plates, is poured. The plates have a special shape and, when assembled, form a cylinder with two poles, on which the stator winding 14 is placed. Between the bottom cover 5 and the body, a getinaks traverse 1 with brush holders is clamped.

The armature has a core made of electrical steel plates. In the grooves of the core, insulated with cardboard, a wave winding is laid, the leads of which are soldered to the copper plates of the collector. The collector is pressed onto the lower end of the shaft, and on the upper (day off) a plastic impeller is installed at the end.

The armature shaft rotates in two ceramic-metal inserts 11, which are held by spring washers embossed in the covers. The outer spherical surface of the liners is surrounded by felt rings. Inserts and felt are impregnated with oil.

The axial free play of the armature shaft is regulated by the selection of washers 10. It should be in the range of 0.1-0.5 mm.

Additional resistor of the electric motor of a heater

The SE-328 type resistor is designed to be included in the power supply circuit of the heater electric motor in order to reduce the rotational speed of its armature. The resistor is fixed with two screws in the heater fan housing.

The resistance value of the resistor is 1 ohm at 20°C.

Heater motor switch

On VAZ-2101 and VAZ-2102 vehicles, switches of the VK-408 type are used to turn on the heater electric motor and change its operating mode, and on VAZ-2103 - VK-408A. These switches have the same device and differ only in that the VK-408A key 15 is chrome plated.

The switch is fixed in the hole of the instrument panel lining with spring holders 17.

The switch has a plastic housing 21, made up of two halves, between which three plugs are clamped. One of the plugs is copper plated. It should be connected to a blue wire with a black stripe from the heater motor. The switch must be installed on the vehicle so that the copper-plated plug is at the top. The middle plug is in permanent connection with the moving contact 18.

Cigarette lighter

On cars «Zhiguli» a cigarette lighter type PT-10 is used. It is mounted on a bracket under the instrument panel. The bracket is clamped with a nut 31 between the body 39 and the light-scattering rim 26.

On the rear side of the cigarette lighter cartridge, a ceramic insulator 32 with a bimetallic spring clip 30 is fixed with a nut 33. A glass with a heating element is inserted into the cartridge from the front side.

The heating element is a spiral made of a special alloy and is mounted on a ceramic insulator 36, which is rigidly connected to the plastic handle 25 through the inner cup 37. One end of the spiral is connected to the cup 35, and the other end is connected to a finger that rivets the cup and the inner cup 37 to the insulator.

When you press the handle 25, the cup 35 is pinched between the tabs of the bimetallic bracket 30 and held in this position. The current from the current source is supplied to the bimetallic bracket and closed to ground through the cup 35, the heating element, the finger, the inner cup and the contact ring. The heating element heats up, the bimetallic bracket also heats up and its paws diverge, releasing the cup - 35. Under the action of the spring 38, the heating element, and with it the handle, return to its original position, signaling that the cigarette lighter is ready for use.

Fan motor

Technical specifications:

- Rated voltage, V - 12

- Rated power, W — 150 (110*)

- Frequency of rotation of the armature shaft with an impeller at rated power, rpm - 2700

- Current consumption at rated power, A - 15 (14*)

* For electric motor ME-272.

On some VAZ-2103 vehicles, an electric motor of the ME-271 or ME-272 type is installed to drive the fan of the engine cooling system. It is a four-pole, four-brush DC motor with permanent magnet excitation.

The ME-271 electric motor has a steel stamped body 6, inside of which four permanent magnets 45 are glued, which are the stator poles. On the front side of the housing there are two ball bearings of the armature shaft. The outer races of the bearings are unclenched by spring disc washers 49. Lubrication is placed between the bearings during assembly. On the back side, the case is closed with a cover 13.

A hub 43, cast from an aluminum alloy, is pressed onto the steel shaft 53 of the anchor. On the hub, the core 47 of the armature, recruited from plates of electrical steel, is poured. In the grooves of the core, insulated with cardboard, the winding 46 of the armature is laid. Collector 3 is pressed onto the armature shaft from the rear side.

A getinax traverse 1 with four brush holders and four electrographite brushes is riveted to the cover 13.

The ME-272 electric motor has a housing 6 cast from aluminum alloy and a cover 13 connected by coupling bolts. A brush holder with four brushes is attached to the cover from the back side.

The front bearing of the armature shaft is ball bearing, and the rear bearing is made of ceramic-metal insert 11.

The electric motor is switched on by sensor 65 (TM-108) through relay 63, which is used as a relay of the RS-527 type, described on the sheet «Switches and relays for lighting and light signaling». The armature winding of the electric motor is protected by a separate fuse 64 for 16 or 25 A.

Fan motor activation sensor

To turn on and off the electric motor of the fan of the engine cooling system on VAZ-2103 vehicles, depending on the temperature of the coolant, a sensor of the TM-108 type is used, which is installed on the left side of the lower radiator tank.

In the brass case 39 of the sensor, the plastic holder of the plugs and the guide 41 of the pusher 19 are rolled. A spring plate 40 with a movable contact is riveted to one of the plugs. A bimetallic washer 42 is installed at the bottom of the housing, at a temperature below 87°C it is curved towards the bottom of the housing. A plastic pusher 19 rests against the center of the washer. At a temperature of 92°C and above, the washer bends towards the pusher, which, in turn, presses on the plate 40 and the sensor contacts close.