Open large image in new tab »

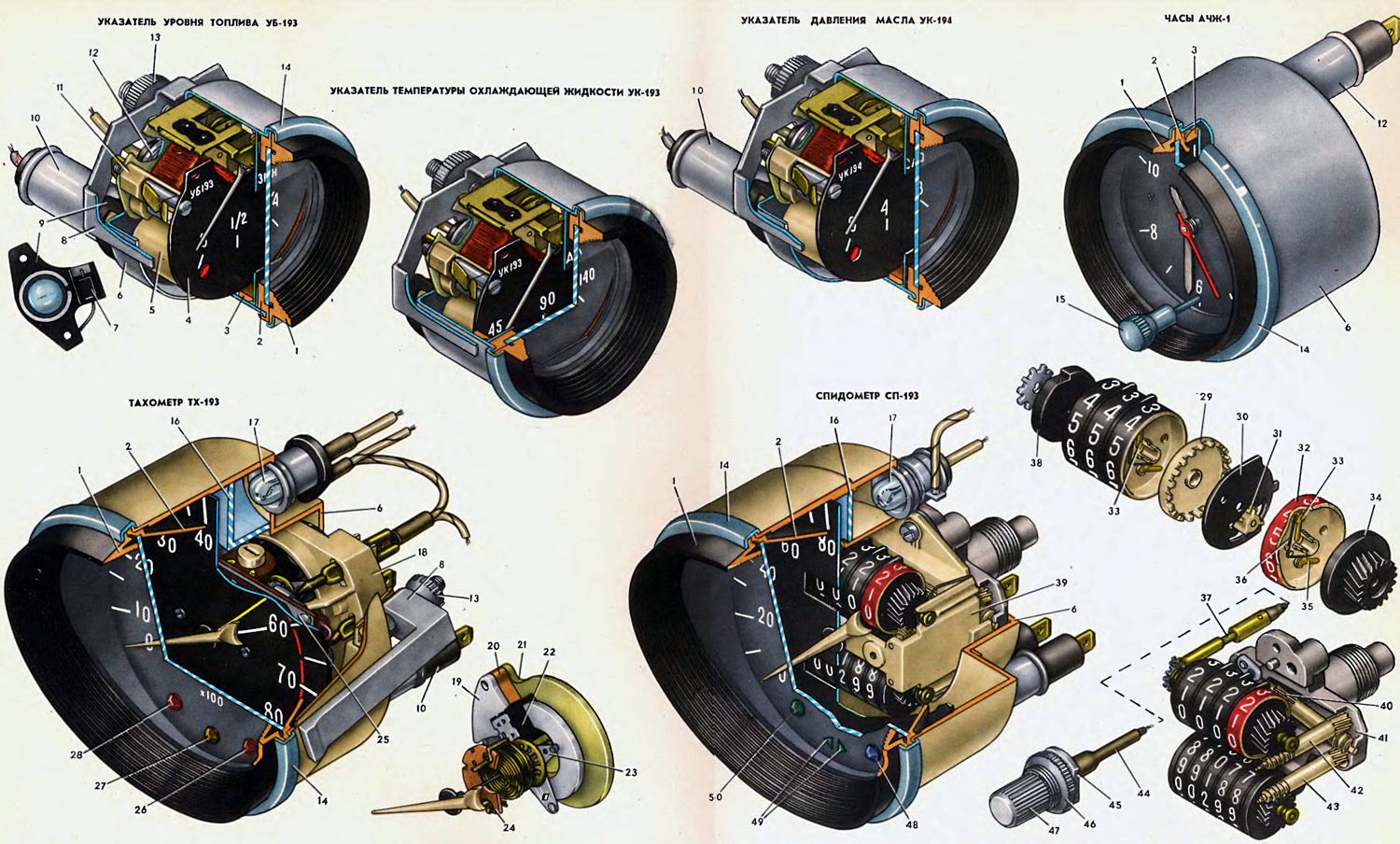

1. Rim. 2. Glass holder. 3. Diffusing bezel. 4. Scale. 5. Sleeve. 6. Body. 7. Device protection diode. 8. Bracket for fastening the device. 9. Bridge. 10. Lampholder of a control lamp. 11. Frame with coils. 12. Lamp holder for scale illumination lamp. 13. Nut of fastening of a bracket. 14. Welt. 15. Arrow setting button. 16. Light filter. 17. Scale illumination lamp. 18. Housing milliammeter. 19. Internal magnetic circuit. 20. Magnet. 21. External magnetic core. 22. Coil milliammeter. 23. Reel holder. 24. Washer with contact petals. 25. Board with the electronic part of the tachometer. 26. Light filter for the control lamp of the battery charge. 27. Light filter for the control lamp for controlling the carburetor air damper. 28. Light filter of the control lamp for turning on the parking brake and insufficient fluid level in the reservoirs of the hydraulic brake drive. 29. Crown. 30. Cheek. 31. Six-toothed gear. 32. Drum. 33. Doggy. 34. Leading disk. 35. Doggy. 36. Spring dogs. 37. Roller for zeroing the daily counter. 38. Cam washer. 39. Case of counters. 40. Meter drive roller. 41. Foundation. 42. Daily counter drive roller. 43. Roller drive totalizer. 44. Cable. 45. Sleeve. 46. Bushing nut. 47. Handle for zeroing the daily counter. 48. Light filter of the control lamp for switching on the main beam of the headlights. 49. Light filter for the control lamp for turning on the direction indicators. 50. Light filter for the control lamp for switching on external lighting.

Fuel gauge

On VAZ-2103 vehicles, a magnetoelectric fuel level indicator of the UB-193 type is used, which operates in conjunction with a BM-150 type sensor. It is attached to the instrument panel using bracket 8 and nut 13.

The pointer has a stamped steel body 6, in which a plastic frame 11 with coils and a scale 4 is fixed with two nuts. A plastic bridge 9 with a lamp holder 10 is riveted to the body on the back side. A silicon diode 7 for protecting car instruments is placed under the bridge, and a cartridge is inserted into the lamp holder 10 with control lamp AMN 12-3 fuel reserve. On the rear side, a lamp holder for the indicator lamp is also welded to the body. On the front side, a plastic glass holder 2 and a rim 1 are riveted to the body with a chrome-plated welt 14.

The device operates in the same way as the UK-191 coolant temperature gauge described on the previous sheet. Depending on the resistance of the sensor, the total magnetic flux of a certain direction acts on the permanent magnet of the pointer, setting the pointer in a certain position.

Coolant temperature gauge

The device type UK-193 is magnetoelectric and has the same design and principle of operation as the fuel gauge UB-193. It differs in other winding data, as well as the absence of a control lamp and a protection diode. The device operates in conjunction with the TM-106 sensor.

Oil pressure gauge

The indicator type UK-194 is magnetoelectric and has the same design as the fuel level indicator UB-193. It differs in other winding data and the absence of a protection diode. An indicator lamp of insufficient oil pressure is inserted into the lamp holder 9, which is turned on by a sensor of the MM-120 type.

The pointer is used in conjunction with an MM3-93A type sensor that changes the resistance of the electrical circuit depending on the oil pressure in the engine lubrication system.

Watch

On the VAZ-2103 car, clocks of the AChZh-1 type with a non-contact magnetoelectric balance drive are used. The clock is installed in the middle part of the instrument panel and is held in it by a plastic ring put on the clock case and tightly fitting into the hole in the instrument panel.

The watch operates at a supply voltage of 8-16 V and consumes no more than 50 mW of power at a supply voltage of 13 V and a temperature of 20°C. The maximum travel error does not exceed 4 minutes in 96 hours at a supply voltage of 13 V and a temperature of 20 C.

The execution of the watch is dustproof. Case U steel stamped. A ground plug is riveted to the case on the back side and a lamp holder 12 is welded for a clock lighting lamp, which is used as a miniature lamp of the AMN12-3 type.

Tachometer

On VAZ-210Z vehicles, an electronic tachometer of the TX-193 type is used. It has a plastic case 6, to which a plastic glass holder 2 and a rim 1 are attached to the front with a chrome-plated metal welt, and a case of 18 milliammeters is attached to the back with three screws.

The principle of operation of the tachometer is based on measuring the frequency of the voltage pulses in the primary circuit of the engine ignition system. As described above (V «Ignition system»), for one revolution of the ignition distributor roller, the breaker contacts open and close four times. Therefore, for one revolution of the roller in the primary circuit of the ignition system, four current and voltage pulses are created. The higher the engine speed, the greater the pulse frequency.

Voltage pulses are taken from the end of the primary winding of the ignition coil and fed to the input of the current pulse shaper, which feed the milliammeter coil. Depending on the frequency of the pulses, the average value of the current passing through the coil winding of the milliammeter changes. The higher the engine speed, the higher the pulse frequency, the higher the average current strength that feeds the coil winding of the milliammeter, and the greater the pointer of the device deviates.

The pulse shaper is a waiting multivibrator on two transistors. The coil winding of the milliammeter is connected to the collector circuit of one of the transistors. The multivibrator is mounted on a board 25 made of foil-coated getinaks, attached to the body of the milliammeter.

The milliammeter is applied magnetoelectric type. Its magnetic system consists of a permanent magnet 20 sandwiched between two magnetic circuits - outer 21 and inner 19. The magnet and magnetic circuits are attached to a plastic case 18. The inner magnetic circuit has an annular part, which is covered by a coil 22, mounted on a holder 23.

The axis of the milliammeter rotates in two bushings. The front bushing is fixed in housing 18, and the rear one is attached to the outer magnetic circuit 21. The ends of the axle are lubricated during assembly with a special silicone fluid, which has a damping property - it dampens the vibrations of the arrow when the car is moving.

The electric current flowing through the winding of the coil 22 creates a magnetic field around it. As a result of the interaction of the magnetic fields of the coil and the permanent magnet 20, a force acts on the coil, which overcomes the resistance of the springs and turns it along with the axis and the arrow at a certain angle. This angle is the greater, the greater the magnitude of the current flowing through the coil winding.

Speedometer

On VAZ-2103 cars, a speedometer of the SP-193 type is used. It is mounted on the instrument panel and attached to it with the same brackets with nuts as the TX-193 tachometer.

The speedometer has a pointer speed indicator and two counters: a totalizing and daily distance traveled, the readings of which can be set to zero with the handle 47. The mechanisms of the speed indicator and the totalizing counter are the same as those of the speedometer in the KP-191 instrument cluster of the VAZ-2101 car.

The speedometer housing is plastic. In the upper part there is a compartment closed with a blue diffuser 16. In this compartment there is a lamp 17 for illuminating the scale. In the lower part of the body there is a compartment divided by partitions into three sections, in which there are control lamps. The light from the lamps passes through colored plastic filters 48, 49 and 50, attached with adhesive tape to the scale.

The counters are installed in a plastic case 39 and are driven by rollers 42 and 43 from the roller 40 installed in a cast metal base 41. The device of the total counter is described on the previous sheet. Therefore, only the daily counter will be described below.

The daily counter has four drums with numbers. Primary drum 32 - red. It counts the hundreds of meters traveled. The rest of the drums count the kilometers.

Just like in the summing counter, cheeks 30 with six-tooth gears 31 are installed between the drums of the daily counter, through which rotation is transmitted from one drum to another. But for the drums of the daily counter, the ring gear is not made in the drums, but on a separate part - the crown 29. The crown is connected to the drums through the pawl 35.

Two pawls are installed on each drum: 33 and 35 with a leaf spring 36. Pawls 33 enter a special groove made along the axis of the drums. The pawls prevent the drums from turning around the axis in the direction of decreasing countdown. Dogs 35 are included in the recesses of the gear rims 29 installed in the drums. Through the pawls, the crown rotates the drum in the direction of increasing the count.

The daily counter works as follows. The roller 42 rotates the drive disk 34, which rotates the drum 32 through the pawl 35. For one complete revolution, the drum 32 with two teeth on the other side rotates the six-tooth gear 31 by 120°, and through the crown 29 it turns 1/10 of the turn the next drum.

When resetting the readings of the daily counter, the roller 37 through the gears rotates the axis of the drums in the direction of increasing the reading. The pawls 33 enter the groove of the axle and all the drums rotate with it until the cam 38 is fixed by a flat spring. This spring is installed in housing 39 and fixes the washer in a position where all the drums show zeros in the scale window.

Roller 37 is driven through cable 44 from handle 47, which is attached to the instrument panel with bushing 45 and nut 46. To set the meter to zero, handle 47 must be rotated counterclockwise. In order not to damage the meter, this should be done on a stationary vehicle.