Carburetor operation when starting and warming up a cold engine

For a reliable start of a cold engine, a strong enrichment of the working mixture is necessary due to the poor quality of mixture formation, caused by low temperatures of engine parts, fuel and air and low air velocities passing through the carburetor. The enrichment of the mixture is provided by a starting device operating as follows.

When starting the engine (see sheet 15) the control handle of the starting device is pulled out to the stop. At the same time, the throttle control pedal must not be touched in order to avoid supplying an uncontrolled excess portion of fuel to the engine. At the same time, under the influence of the cable 25, the lever 27 turns counterclockwise, the telescopic rod 26 closes the air damper 19 through the lever 20. The end of the rod 21, moving in the slot of the rod 22 of the diaphragm 45 of the starting device, occupies the extreme left position, and the rod 38, going down, turns the lever 34, which with its right spike acts on the stop 32 of the lever 36 and slightly opens the throttle valve 28 to the required angle. When the engine is turned by the starter, the resulting vacuum is transmitted to the openings of the idle system and through the ajar throttle valve of the primary chamber to the sprayer of the main metering system. Under the influence of this rarefaction, the fuel begins to intensively flow out of the holes of the idle system and the atomizer. At the same time, the vacuum is transmitted through channel 66 and jet 43 into the working cavity of diaphragm 45, but it is not yet able to overcome the resistance of the return spring, and the diaphragm remains stationary. At the time of engine start (emergence of sustained outbreaks) the vacuum in the intake pipe increases sharply, under the action of which the diaphragm 45 with the rod 22 is retracted and, with the help of the rod 21 and the lever 20, slightly opens the air damper 19. The lever 20 rotates in the direction of opening the damper, since the telescopic rod 26, which has a spring inside, is compressed.

The extreme extended position of the diaphragm 45 is determined by the installation of the adjusting screw 44; the screw is set at the factory and should not be disturbed. For cases when it is necessary to install screw 44 on your own, you should be guided by the fact that when the trigger control handle is fully extended and the thrust 21 is actuated towards the trigger, the air damper should open slightly and the gap between its lower edge and the wall of the inlet neck would be 7–7.5 mm.

All elements of the starting device are selected in such a way that the air damper opens or closes automatically when starting and starting to warm up the engine, preventing excessive enrichment or depletion of the mixture.

As the engine warms up, the air damper is fully opened, gradually returning the starter control handle to its original position.

The carburetor starting system for VAZ vehicles ensures the successful start of a serviceable and properly adjusted engine without any preliminary preparation to temperatures of -25°C.

Carburetor idle

Open large image in new tab »

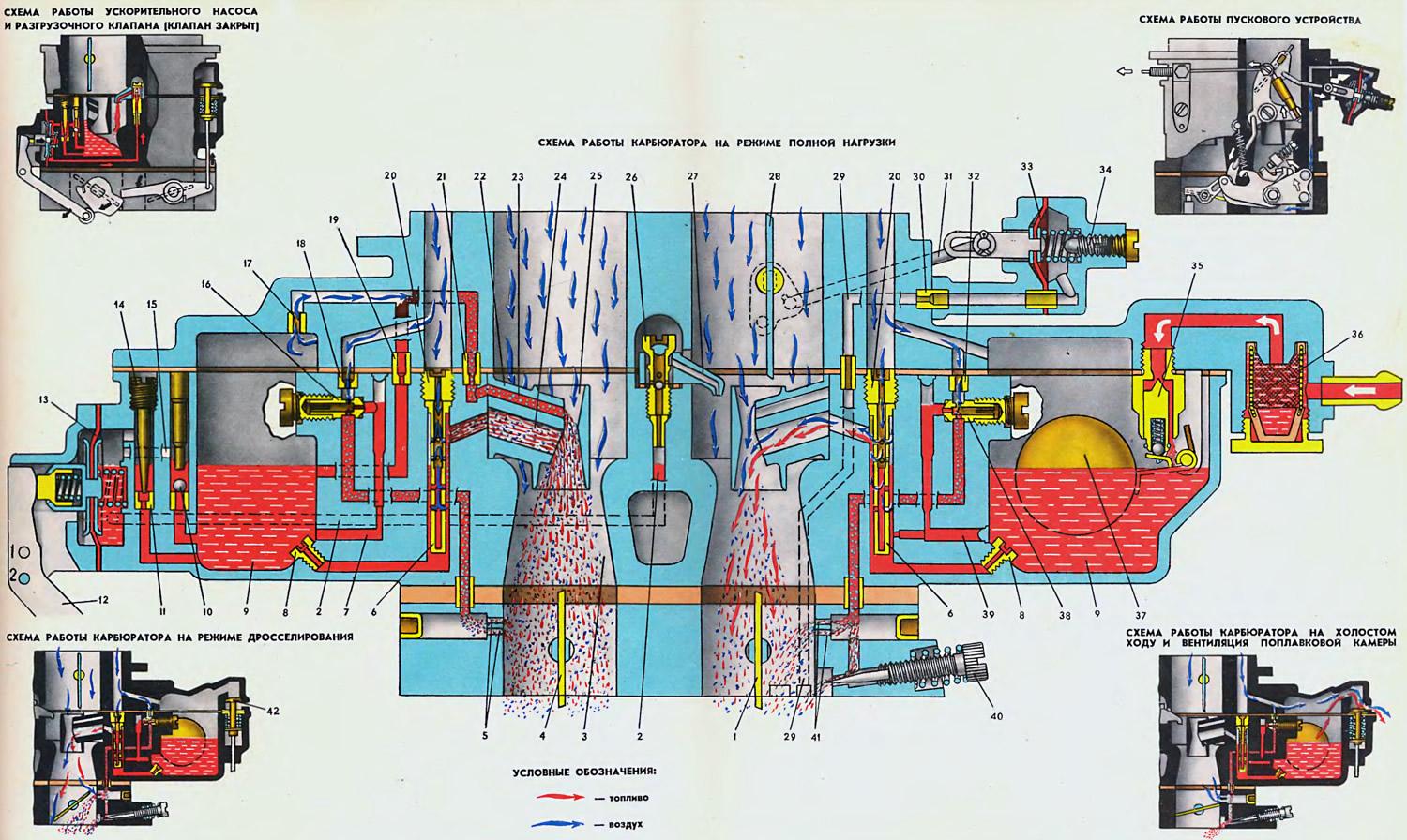

1. Throttle valve of the primary mixing chamber. 2. Fuel supply channel to the accelerator pump atomizer valve. 3. Large diffuser. 4. Throttle valve of the secondary mixing chamber. 5. Non-adjustable transition system holes. 6. Emulsion tube. 7. Channel for supplying fuel to the transition system. 8. Main fuel jet. 9. Float chamber. 10. Accelerator pump inlet valve. 11. Accelerator pump jet. 12. Accelerator pump lever. 13. Accelerator pump diaphragm. 14. Accelerator pump adjusting screw. 15. Fuel supply channel to the accelerator pump chamber. 16. Fuel jet of the transition system. 17. Econostat air jet. 18. Air jet of the transition system. 19. Econostat fuel jet. 20. Air jet of the main dosing system. 21. Econostat emulsion jet. 22. Body sprayers. 23. Econostat atomizer. 24. Atomizer of the main dosing system. 25. Small diffuser. 26. Delivery valve of the accelerator pump sprayer. 27. Accelerator pump spray nozzle. 28. Air damper. 29. Communication channel of the starting device with the throttle space. 30. Air jet launcher. 31. Rod connecting the starting device with the air damper. 32. Air jet of the idle system. 33. Diaphragm of the starting device. 34. Trigger adjustment screw. 35. Float chamber needle valve. 36. Filter element. 37. Float. 38. Fuel jet of the idle system. 39. Channel for supplying fuel to the idle system. 40. Adjusting screw for the composition of the mixture when the engine is idling (quality screw). 41. Transition holes of the idle system. 42. Unloading valve of the float chamber.

At idle, the throttle valve 1 is ajar, while the vias 41 of the idle system are located above the upper edge of the damper. Air damper 28 is fully open. Vacuum due to throttle valve 1 through the hole covered with adjusting screw 40 (on carburetors 2103-1107010-01 this hole is brought to the center of the throttle body), is transmitted to the fuel jet 38 of the idle system. Under the action of vacuum, the fuel entering the emulsion well through the main fuel jet 8 rises to the fuel jet 38, partially mixes with the air entering through the air jet 32 of the idle system, re-mixes with the air entering through the vias 41, and through the hole, regulated by screw 40 enters the engine inlet pipeline. The fuel level in the emulsion well decreases and becomes less than the level in the float chamber. The difference in levels creates a pressure, under the influence of which, in this case, the fuel flows out of the main fuel jet 8. In this mode, the vacuum in the small diffuser at the atomizer of the main metering system is insignificant and no fuel enters the engine through it.

On carburetors 2103-1107010-01, when power is removed from the solenoid valve, the hole of the fuel jet 38 is blocked by a shut-off needle and the only way through which fuel can enter the engine with the throttles closed to the stop and the air damper open, closes, which ensures that there is no possibility of spontaneous engine operation.

To control the idle speed in the carburetor there is an adjusting screw 40 of the mixture composition and a stop screw 30 (see sheet. 15), which sets the initial throttle opening of the primary chamber. When screw 40 is screwed in, the mixture becomes leaner; when screw 30 is screwed in, the throttle valve opens slightly.

Due to the current toxicity regulations limiting the maximum allowable content of carbon monoxide (SO) when the engine is idling, idle speed control must be carried out in strict accordance with the factory instructions, which do not allow an increase in carbon monoxide emissions above the established norms.

Idling speed is adjusted as follows. On a warm, serviceable and fully equipped engine with adjusted clearances in the valve mechanism and the correct ignition setting, using screw 40 of the mixture composition, the maximum idle speed is set at a given position of the stop screw 30 (see sheet 15) throttle valve. The stop screw 30 sets the idle speed in the range of 750-800 rpm. Screw 40 sets the concentration of carbon monoxide within 3±0.5% at a given position of the stop screw.

In the absence of a gas analyzer, idle speed control is carried out as follows. Thrust screw 30 sets the engine speed in the range of 750-800 rpm, and screw 40 sets the maximum engine speed at a given position of the stop screw; with a stop screw, reduce the engine speed to 750-800 rpm, turning screw 40 of the mixture composition, achieve engine operation with noticeable unevenness and then unscrew screw 40 (30-60°no more) until stable engine operation is achieved.

The correctness of the regulation is also checked by sharply pressing the throttle pedal and releasing the gas - the engine should not stall.

Carburetor operation in throttling modes

In throttling modes, the primary chamber mainly works, which ensures the operation of the engine in a wide range. The required composition of the mixture is ensured by the joint operation of the idle system and the main dosing system.

As the throttle valve 1 of the primary chamber opens, the vias 41 fall under the action of the throttle vacuum and stop working as air jets. Through them, the air-fuel mixture also begins to flow. With further opening of the throttle valve, the vacuum in the atomizer increases, the fuel in the emulsion well begins to rise and, when it reaches the bottom row of holes in the emulsion tube 6, it is captured by air entering the emulsion tube through the air jet 20 of the main metering system, and is drawn into the atomizer 24. From this moment, the joint operation of the idle system and the main dosing system.

After the throttle valve 1 has rotated approximately 48°from its original position, the throttle valve 4 of the secondary chamber begins to open. Both dampers come to the fully open position at the same time. The absence of failures in the operation of the engine is ensured by holes 5.

The secondary chamber works similarly to the first one, with the exception of idling, since hole 5 is located above the upper edge of the throttle valve and vacuum is not transmitted from the throttle space to the channels of the metering systems. Maximum throttle closing 4 is limited by screw 30 (see sheet 15) whose position is set at the factory. After adjustment, the screw 30 is centered.

Carburetor operation at full load (throttle valves are fully open)

When the throttle valves are fully opened, the vacuum in the idling channels of the primary chamber and in the channels of the transitional system of the secondary chamber drops, and in small diffusers it increases, as a result of which the air-fuel mixture intensively flows out of the atomizers. Due to the presence of air jets 20 having large flow sections, as well as very large flow sections of the channels of the atomizers and the channel connecting the atomizer to the emulsion well, the vacuum in the well still remains less than the vacuum in the region of the holes 41. Therefore, the idle system and the transition system The secondary chambers work as fuel chambers and there is no excessive leaning of the mixture, however, the amount of fuel supplied to the engine in these modes through the mentioned systems is insignificant.

The work of the econostat

Econostat is an autonomous metering system with its own fuel 19, air 17 and emulsion jets, designed for additional enrichment of the mixture at full load. The econostat comes into operation when the vacuum in the atomizer reaches the required value. This system is made only in the carburetor 2101-1107010-02; it is not used in carburetor 2103-1107010-01.

Accelerator pump operation

To enrich the mixture in the acceleration mode, an accelerator pump is used, which injects an additional portion of fuel into the air stream passing through the carburetor. Fuel enters the working cavity of the pump from the float chamber 9 through the inlet ball valve 10 and jet 11. When the throttle valve is suddenly opened, cam 61 (see sheet 15) the accelerator pump drive turns and acts on the lever 62, which compresses the spring placed inside the telescopic cup of the working diaphragm 64. Expanding, the spring smoothly moves the diaphragm 64, which ensures prolonged fuel injection. When the diaphragm 13 of the pump moves, the fuel enters the pressure valve 26 through channel 2 and is then injected through the spray nozzle into the primary mixing chamber of the carburetor. Cam 61 (sheet 15) has a special profile, due to which a double fuel injection is provided, and the second injection coincides with the beginning of the opening of the throttle valve 4 of the chamber. The axis of the accelerator pump drive lever can be installed on the accelerator pump cover in the positions indicated by the numbers 1 and 2, which depends on the adjustment adopted at the factory.

Unloader operation

Unloader valve 52 (see sheet 15) provides access to fuel vapors from the float chamber to the atmosphere with closed throttle valves to ensure the start of a hot engine. When the throttle valves are opened, the cam 61, turning, releases the lever 56, which turns counterclockwise under the action of the spring, and, acting on the rod 7, presses the valve 52 to the seat, which balances the chamber with the throttle valves open. The unloader valve is installed only on the carburetor 2101-1107010-02.