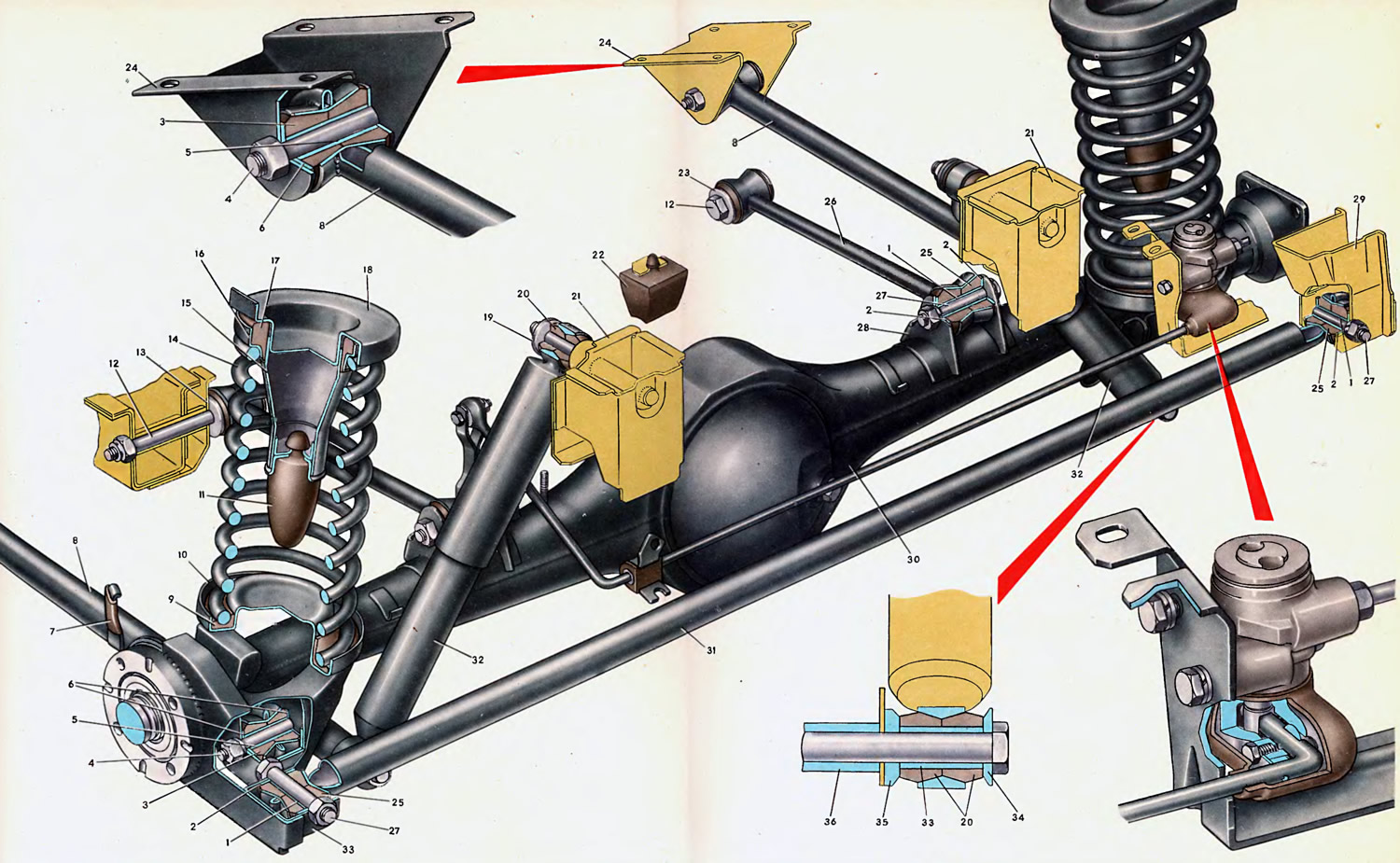

The rear wheel suspension has devices specific to each suspension, i.e., guiding, elastic and damping.

Guiding device. The rear axle beam is attached to the car body using torque rods: two upper longitudinal, two lower longitudinal and one transverse.

Longitudinal rods serve to transfer pushing and braking forces from the drive wheels through the beam to the body, the transverse rod keeps the body from lateral movements.

All rod fastenings, both on the rear axle beam and to the body, are articulated, made on rubber bushings, and do not require additional maintenance and lubrication during operation.

Open large image in new tab »

1. Spacer. 2. Thrust washer. 3. Tapered rubber bushing of the lower rod. 4. A bolt of fastening of a head of the lower bar. 5. Spacer. 6. Thrust washer. 7. Bracket for fastening the parking brake cable. 8. Lower longitudinal bar. 9. Insulating plastic gasket. 10. Cup of the lower spring support. 11. Main compression buffer. 12. Upper rod head bolt. 13. Body floor spar. 14. Spring. 15. Compression buffer support. 16. Support cup. 17. Rubber insulating gasket 18. Upper spring seat. 19. Washer. 20. Rubber bushing. 21. Bracket for the cross member of the rear floor of the body. 22. Additional compression buffer. 23. Front head of the upper rod. 24. Bracket for fastening the front head of the lower rod. 25. Tapered rubber bushing of the upper and transverse rods. 26. Upper longitudinal bar. 27. Bolt for fastening the heads of the upper and transverse rods. 28. Bracket for mounting the rear head of the upper rod. 29. Bracket for fastening the right head of the transverse rod. 30. Rear axle beam. 31. Cross bar. 32. Shock absorber. 33. Bracket for fastening the left head of the transverse rod. 34. Clamping washer. 35. Washer. 36. Distance sleeve.

The design of the transverse 31 and lower rods 8 is of the same type and is a steel pipe ∅ 30X26 mm, to the flattened ends of which cone heads are welded. Rubber bushings 3 and 25, made in the form of truncated cones, are pressed into these heads. This design of the bushings creates a good fixation in the head of the rod. From the outside, the rubber bushings are pressed with steel washers 2 and 6. The washers are fixed by flaring the flanges of the steel spacer bushings 5 and 1 inserted into the holes of the rubber bushings.

Heads with pressed-in bushings of the lower longitudinal rods are longer than the heads of the transverse rod, since the lower rods are the main ones and carry a large load.

The upper longitudinal rods 26 are shorter than the lower ones and are steel rods ∅ 16 mm with tapered bushings welded at the ends, similar in design to the heads of the other rods.

A bracket 7 for fastening the parking brake cable is welded to the pipe of the lower longitudinal rods from the outside by relief welding. Bracket 7 limits the lateral displacement of the cable.

All torque arms are painted black for corrosion protection and a decorative look.

The front heads of the lower longitudinal rods are attached to the brackets 24 of the body using bolts 4. The rear heads of the rods are reinforced with bolts 4 in the brackets welded from below to the rear axle beam.

The front heads of the upper longitudinal rods are fastened with 12 bolts with self-locking nuts (with nylon inserts) to the inner wall of the spars 13 of the floor of the body, and the rear heads of the rods - to the brackets 28, Welded on top to the beam 30 of the rear axle, bolts 27 with nuts and spring washers.

The left head of the transverse rod is attached to the bracket 33, welded to the flange and the housing of the rear axle beam, and the right head is attached to the bracket 29 with bolts, nuts and spring washers.

The final tightening of the fastening nuts with a torque of 8 kgf·m for all torque rods is carried out on a vehicle with a conditional load of 320 kg (4 people plus 40 kg of cargo in the trunk). This is done in order to provide optimal conditions for the operation of swivel joints. Tightening the fasteners gives a tight fit of the clamping washers 6, 2 and spacer bushings 5 and 1 to the cheeks of the brackets and does not allow these parts to rotate when the body or suspension vibrates relative to the mounting bolts.

The swinging of the rods during vibrations occurs only due to the elastic deformation of the rubber bushings without their slipping.

elastic device. The main element of the elastic device is a twisted cylindrical spring 14. The spring is made by coiling in a heated state from a ground bar of chromium-silicon steel, hardened with high tempering (improvement) and shot peened to improve fatigue strength. After processing, a protective polyamide coating is applied to the rear spring, and the front spring is painted.

The springs are sorted by length into two groups under a static load of 295 kg. On the outer side of the springs, the group is marked with paint in the same way as the front suspension spring groups, i.e. group A - yellow stripe, group B - green stripe.

The spring mounted on the suspension is pre-compressed with a force of up to 65-70 kgf. The upper end of the spring rests against the support 18, welded to the rear wheel arch. A rubber insulating gasket 17 and a stamped steel cup 16 are installed between the support 18 and the spring.

The lower end of the spring abuts through an insulating plastic gasket 9 into the cup 10 welded to the beam 30 of the rear axle.

Rear suspension travel is limited to two main 11 and one additional 22 compression buffers. The buffers are made of rubber that works well in compression and are additional elastic elements that increase the stiffness of the suspension at the end of the compression stroke.

The main buffers 11 are installed inside the springs and are fixed with a mushroom-shaped nipple in the holes of the upper supports 15. At the end of the compression stroke, the buffer rests against the disc-shaped bottom of the lower cup 10.

Additional buffer 22 is mounted on a bracket bolted to the bottom of the body (This bracket also serves to attach seat belts), and at the end of the suspension compression stroke rests against a special platform on the crankcase of the rear axle gearbox.

Extinguishing device. Just like on the front suspension, two hydraulic shock absorbers are used as the main element of the damping device.

Unlike the front shock absorbers, the rear shock absorbers have two heads for connecting to the attachment points. All shock absorber mounts are articulated, on rubber bushings, which, when the suspension and body vibrate, work due to the elastic deformation of the rubber. During operation, these swivel joints do not need lubrication. Estimated deflection angle of shock absorber (during fluctuations) - with a compression stroke of 9 and with a recoil stroke of 10°.

The shock absorber with the upper head is mounted on a pin welded to the bracket 21 of the cross member of the rear floor of the body. When attaching the shock absorber, two rubber bushings 20 are inserted into the conical hole of the head, then pressed in with a washer 19 and a self-locking nut. The lower head of the shock absorber is attached to the ears of the lower longitudinal rod mounting bracket using a bolt with a self-locking nut. When fastening, two rubber bushings 20 are also inserted into the tapered hole of the head, and a steel spacer bushing 33 is inserted into the holes of the bushings. The rubber bushings are pressed on both sides with steel washers 34 and 35. To protect the ears of the bracket from deformation when the nut is tightened, a remote steel bushing is inserted between them 36. The final tightening of the upper and lower fastening nuts with a torque of 6 kgf·m is carried out with a vehicle load of 320 kg (4 people + 40 kg of cargo in the trunk).

The bushings of the swivel joints and the insulating gaskets of the springs are also elements of the damping device, absorbing micro-oscillations and reducing body vibrations that occur when the vehicle is moving.