Check with a set of probes the gaps between the teeth of the gears, as well as between the outer diameters of the gears and the walls of the pump casing, which should be 0.15 mm, respectively (maximum allowable 0.25 mm) and 0.11-0.18 mm (maximum allowable 0.25 mm). If the clearances exceed the limit values, then replace the gears, and, if necessary, the pump housing.

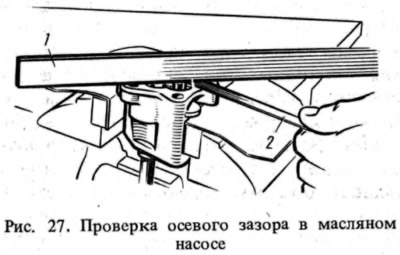

Feeler gauge 2 checks the gap between the ends of the gears and the ruler 1 (pic. 27), which should be 0.066-0.161 mm (maximum allowable 0.20 mm). If the gap is greater than 0.20 mm, replace the gears or housing, depending on what is worn.

Measure the diameters and determine the gap between the axle and the driven gear, which should be 0.017-0.057 mm (maximum allowable 0.10 mm), as well as between the pump shaft and the hole in the housing, which should be 0.016-0.055 mm (maximum allowable 0.10 mm). If necessary, replace worn parts.

When repairing the pump, pay attention to the surfaces of the pressure reducing valve and the housing, which should be free of dirt, deposits, nicks, burrs, which can lead to valve jamming or reduce the oil pressure in the system. Check the elasticity and length of the pressure reducing valve spring and compare with the data above.

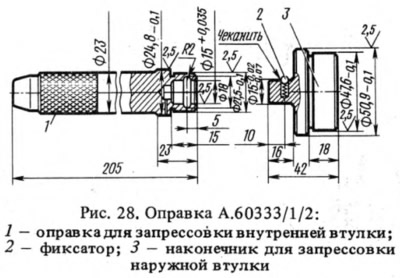

Check the ovality of the roller bushings 10 (see fig. 24) oil pump drive and ignition distributor, their pressing into the sockets, as well as the coincidence of the hole in the front bushing with the channel in the cylinder block, that is, whether the bushing has turned. By measuring the diameters of the roller and bushings, the gaps are determined. If gaps exceed 0.15 mm (wear limit), and also have surface damage or weakening of the pressing, the bushings are replaced. To replace the bushings, use the mandrel A.60333/1/2 (pic. 28). After pressing in, the bushings must be finished with a stepped reamer A.90353 to the dimensions indicated in Table. 2. The reamer processes both bushings at once to maintain their alignment.

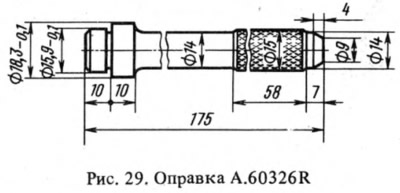

It is not allowed to loosen the fitting and ovality of the bushing of the oil pump drive gear and the ignition distributor. The inner surface must be smooth, without scoring, otherwise the sleeve is replaced with a new one. A.60326R mandrel is used for pressing in and out (pic. 29). After pressing, the sleeve is expanded to a diameter of 16.016-16.037 mm.