Inserts without a groove on the inner surface are placed in the seat of the middle main bearing and in its cover, and in the remaining seats and corresponding covers - liners with a groove1. The crankshaft is placed in the main bearings and two thrust half rings are inserted into the sockets of the rear support with recesses to the thrust surfaces of the crankshaft, and a steel-aluminum half ring is placed on the front side of the rear support, and a metal-ceramic semi-ring is placed on the rear side (yellow color). On engines manufactured before 1980, a ceramic-metal semi-ring must also be installed.

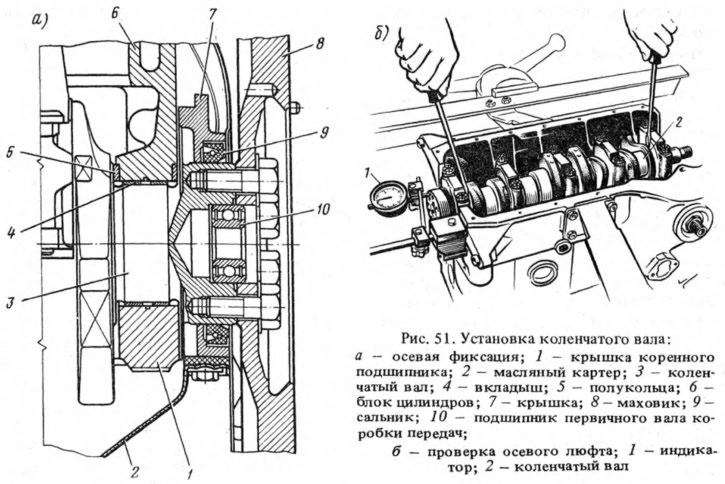

Install the main bearing caps according to the marks (pic. 50). Then check the axial play of the crankshaft (clearance between thrust washers and thrust surfaces of the crankshaft). To do this, set indicator 1, as shown in Fig. 51, b, and move the shaft with screwdrivers, checking the axial play on the indicator, which should be in the range of 0.06-0.26 mm. If the gap exceeds 0.26 mm, the thrust half rings 5 are replaced with new or repair ones, increased by 0.127 mm.

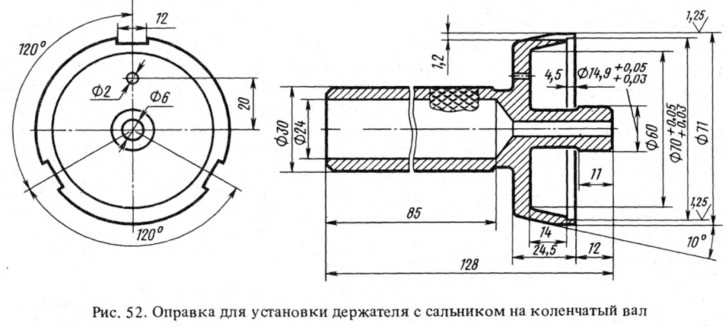

The gasket of the rear oil seal holder is put on the crankshaft flange, and the bolts of the front cover of the clutch housing are inserted into the sockets of the holder. Put on the holder with the stuffing box on the mandrel 41.7853.4011 (pic. 52) and, moving it from the mandrel to the crankshaft flange, is attached to the cylinder block. Install the front cover 6 on two centering bushings (see fig. 48) clutch housing.

Install the flywheel on the crankshaft so that mark B (cone-shaped hole) near the rim (see fig. eleven) was against the axis of the connecting rod journal of the 4th cylinder. After that, block the flywheel with lock A.60330/R (see fig. 48) and attached to the crankshaft flange.

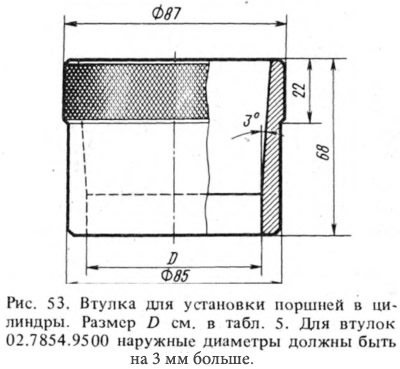

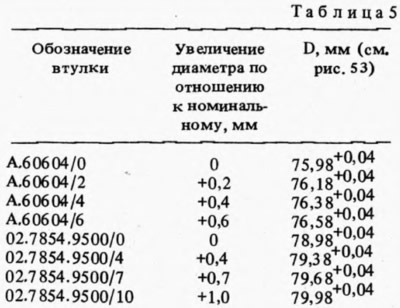

With bushing (pic. 53) from set A.60604 for engines 2101 or 02.7854.9500 for engines 21011, pistons with connecting rods are inserted into the cylinders. Label "P" on the pistons must face the front of the engine. Sleeve sets (tab. 5) for crimping piston rings during installation of pistons in cylinders include four bushings - one for pistons of nominal size and three for increased (repair) serving size. Therefore, it is necessary to select a bushing suitable for the size of the piston to be installed.

Install the liners in the connecting rods and connecting rod caps, connect the connecting rods to the crankshaft journals and tighten the connecting rod bolts. The caps are installed so that the cylinder number on the cap is opposite the cylinder number on the bottom head of the connecting rod.

They put an asterisk, an oil pump drive roller on the crankshaft and fix it with a thrust flange.

Install the cylinder head with a gasket along two centering bushings on the block and tighten the mounting bolts in 2 steps, as indicated in Sec. "Cylinder head and valve train".

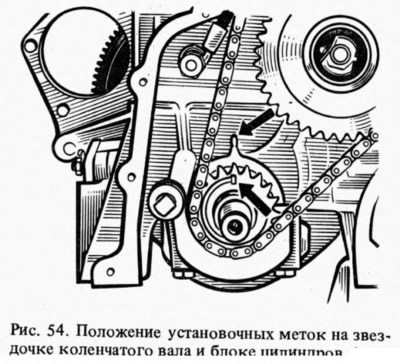

Turn the flywheel so that the mark on the crankshaft sprocket matches the mark on the cylinder block (pic. 54). put on (previously) sprocket on the camshaft, assembled with the bearing housing, and turn it so that mark A (see fig. 56) on the sprocket was against mark B on the bearing housing, then remove the sprocket and, without knocking down the position of the shaft, install the bearing housing on the cylinder head and fix it by tightening the nuts in a certain sequence (see fig. 12). After that, a chain damper is installed on the cylinder head.

Install the camshaft drive chain in the following sequence:

- lubricate the chain with engine oil, put it on the camshaft sprocket and insert it from above into the drive cavity, setting the sprocket so that the mark on it matches the mark on the bearing housing (see fig. 56). Then install the lock washer and the sprocket mounting bolt, without tightening it all the way;

- an asterisk, a lock washer and a bolt are installed on the oil pump drive roller, without finally tightening it;

- put the chain on the crankshaft sprocket and install the chain tensioner shoe and tensioner without tightening the cap nut so that the tensioner spring can press the shoe; wrap the restrictive finger of the chain in the cylinder block;

- turn the crankshaft two turns in the direction of rotation, which will provide the necessary chain tension, and check that the marks on the sprockets match the marks on the cylinder block (see fig. 54) and on the bearing housing (see fig. 56). If the marks match, then, having blocked the flywheel with lock A.60330 / R, finally tighten the sprocket bolts, the cap nut of the chain tensioner and bend the lock washers of the sprocket bolts. If the marks do not match, then repeat the operation to install the asterisk.

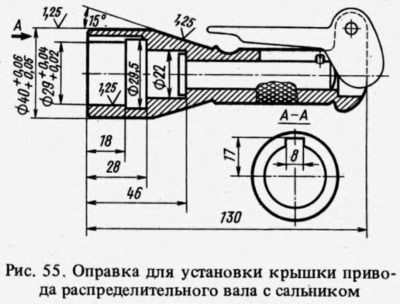

Adjust the gap between the camshaft cams and the valve levers. Install the camshaft drive cover with gasket and oil seal on the cylinder block, without finally tightening the bolts and nuts. Mandrel 41.7853.4010 (pic. 55) center the position of the cover relative to the end of the crankshaft and finally tighten the nuts and bolts of its fastening. Install the crankshaft pulley and wrap the ratchet.

Lubricate the oil filter ring with oil at the raft and install the filter by screwing it manually to the fitting on the cylinder block, Install the crankcase ventilation oil separator, the breather cover and fix the oil separator drain tube retainer. Install the oil pump and oil sump with gasket.

Install the coolant pump, alternator bracket and alternator. Put the belt on the pulleys and adjust its tension. The inlet pipe of the heater radiator and the exhaust pipe are installed on the cylinder head. Attach the heater core outlet pipe to the coolant pump and exhaust manifold. Install the sensors of control devices, the oil pump drive gear and the ignition distributor.

They put the ignition distributor, for which:

- remove the cover from the ignition distributor, check and, if necessary, adjust the gap between the breaker contacts;

- turn the crankshaft until the start of the compression stroke in the 1st cylinder, and then, continuing to turn the crankshaft, align mark 4 with mark 2 (see fig. 57);

- rotate the rotor to such a position that its outer contact will be directed towards the contact of the 1st cylinder on the cover of the ignition distributor and, holding the distributor shaft from turning, insert it into the socket on the cylinder block so that the center line passing through the spring latches, was approximately parallel to the centerline of the engine.

Fix the distributor on the cylinder block, install the cover and attach the wires.

Screw the spark plugs into the cylinder head using the wrench 67.7812.9515 and tighten with a torque handle.

The fuel pump is installed in accordance with the instructions in Sec. 1.9 "Supply system". Install a heat-insulating shield with gaskets, a carburetor and attach hoses to it. The carburetor is closed with a technological plug. Install the cylinder head cover with gasket and fuel line bracket. Pour oil into the neck on the cylinder head cover.

Notes

1. Since 1987, all lower main bearing shells have been used without grooves on the inner surface.