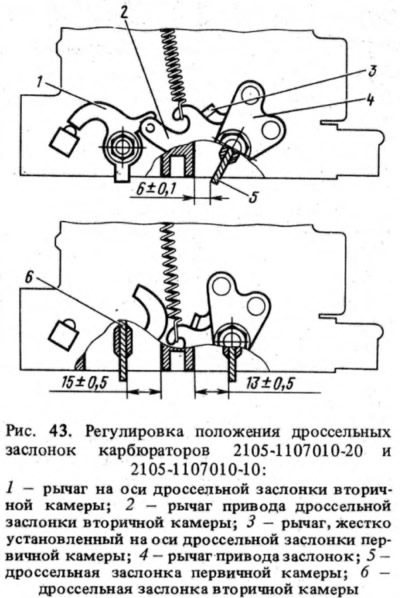

When adjusting the throttle positions for carburetors 2105-1107010-20 and 2105-1107010-10, they check the full opening of the throttle valves when the drive levers are turned all the way, Maximum throttle opening of the primary chamber (13 mm±0.5 mm) 3 (pic. 43); the same for the throttle valve of the secondary chamber (15 mm±0.5 mm) - screwing in or unscrewing the pneumatic drive rod. Partial throttle opening of the primary chamber (6 mm±0.1 mm), at which the upper antennae of the lever 3 is in contact with the lever 2, is adjusted by bending the upper antennae of the lever 3.

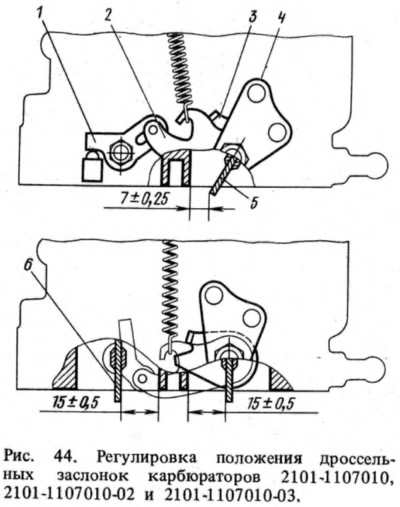

For carburetors 2101-1107010-03, 2101-1107010-02 and 2101-1107010 at lever position 4 (pic. 44), when the upper antennae of lever 3 comes into contact with lever 2, the throttle valve of the primary chamber should be ajar (7±0,25) mm. It is adjusted by bending the upper antenna of the lever 3. Both throttle valves must be fully open when the lever 4 is turned to the extreme position until the antenna of the lever 3 stops against a special tide on the throttle body. Adjustable by bending the lower end of the lever 3.

When adjusting the starting device, turn the lever 1 (see fig. 34) counterclockwise to the stop. In this case, the air damper must be completely closed. In this position of the lever, the end of the rod 3 must be at the end of the groove of the rod 4, without moving the rod. When the air damper is completely closed, the throttle valve 6 of the primary chamber must be ajar for carburetors 2105-1107010-20 and 2105-1107010-10 by 0.7-0.8 mm (gap C). Adjustable by bending the rod 7. Gap C for carburetors 2101-1107010 should be 0.75-0.85 mm, for carburetors 2101-1107010-03 and 2101-1107010-02 - 0.80-0.85 mm. A fully closed air damper should open (clearance B) when moving the rod 4 manually until it stops on (7±0,25) mm for carburetors 2101-1107010-03, (8±0,5) mm for carburetors 2101-1107010-02 and 2101-1107010, (5±0,5) mm for carburetors 2105-1107010-20 and 2105-1107010-10. This value is adjusted by screw 5.

The opening of the float chamber unbalance valve is checked with the throttle valves fully closed.

The supply of the accelerator pump is checked for 10 full turns of the lever 5 (see fig. 32) throttle valve. Fuel from the atomizer is collected in a beaker. Its volume should be 5.25-8.75 cm3. Before starting the test, 10 test turns must be made (moves) to fill the channels of the accelerator pump.

The tightness of the needle valve is checked on the stand, which provides fuel supply to the carburetor under a pressure of 3 m of water column. After setting the level in the test tube of the stand, its fall is not allowed for 10-15 s. A drop in level in the vial indicates fuel leaking through the needle valve.