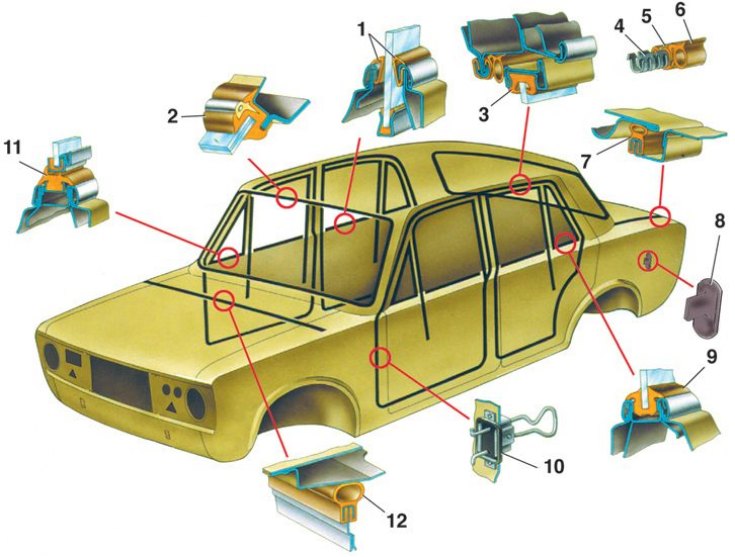

Body rubber seals

1 - lower door glass seal; 2 - windshield and rear windows; 3 - sliding glass; 4 – seal frame; 5 - sealant edge; 6 - sealant of the doorway; 7 - trunk lids; 8 - bumper bracket; 9 - fixed door glass; 10 – laying of the limiter of opening of a door; 11 - rotary glass; 12 - hood

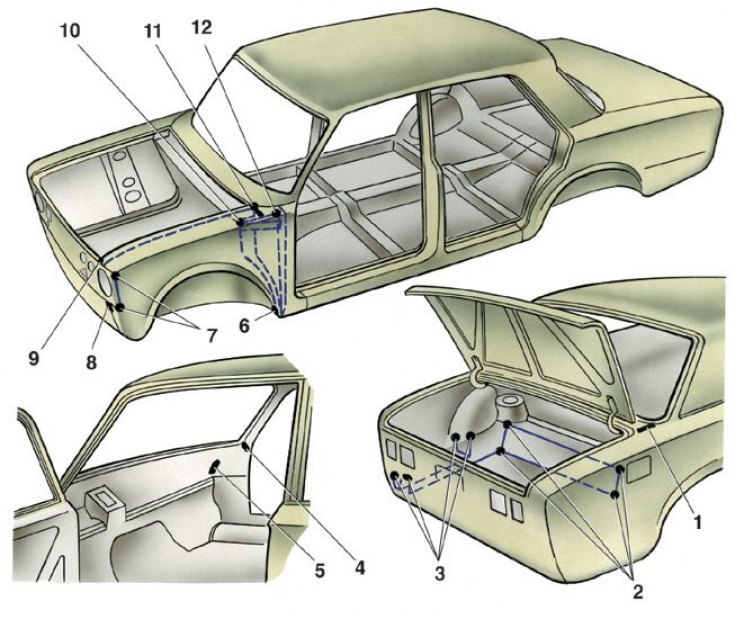

Places for applying non-drying sealing mastic

1 - joints of the rear fenders with the rear panel (inside the body); 2 - corners of the joints of the trunk floor with the rear floor; 3 - the joint of the floors under the spare wheel (fuel tank) with rear panel, spars and rear fenders; 4 - joints of the bases of the inclined part of the front pillars; 5 - joints of the side panels of the bulkhead with the upper amplifiers of the bulkhead shield; 6 - joints of the bulkhead with the side panels of the bulkhead; 7 - joints of the front wings with wing connectors; 8 - joints of the wing connector with mudguards, 9 - joints of the wing amplifiers with the upper cross member of the front end; 10 - joints in the corners of the lower front panel; 11 - corners and joints of the wind window frame panel with wings and drain grooves; 12 - joints of amplifiers with front struts of sidewalls

Sealing is ensured by the use of various rubber seals, sealing mastics, rubber plugs for technological holes and careful fitting of mating parts.

When removing or installing seals with metal frames, do not allow the frame to crumple, and corrugations form on the seals.

Seams of resistance spot welding, which are welded to stamped body parts, do not give a tight connection. They are subject to intense corrosion, especially on bends of sheets with small rounding radii and in places of metal overstress.

From moisture, dirt, welds are sealed with D-4A plastisol.

When replacing individual parts of the body, after welding and applying the primer, coat the seams on both sides with D-4A plastisol. Apply non-drying sealing mastic 51-G-7 to the corner joints and gaps shown in the figure.