Brake system of cars VAZ-21011 «Zhiguli»

Service brake system — design description

Brake system diagram 1 – a protective casing of a forward brake; 2, 18 - pipelines connecting two front brake caliper cylinders; 3 - support; 4 – hydraulic drive reservoir; 5 -...

Brake system diagram 1 – a protective casing of a forward brake; 2, 18 - pipelines connecting two front brake caliper cylinders; 3 - support; 4 – hydraulic drive reservoir; 5 -...

Parking brake — general information

Mechanical drive includes 3 lever (see fig. Parking brake drive parts ), which, together with the return lever, is mounted on a bracket that is attached to the floor of the body....

Mechanical drive includes 3 lever (see fig. Parking brake drive parts ), which, together with the return lever, is mounted on a bracket that is attached to the floor of the body....

Checking pipelines and connections

1. To prevent sudden failure of the brake system, carefully check the condition of all pipelines: metal pipelines should not have dents, cracks and should be located away from...

1. To prevent sudden failure of the brake system, carefully check the condition of all pipelines: metal pipelines should not have dents, cracks and should be located away from...

Brake pedal free travel adjustment

Brake pedal 1 – main cylinder; 2 - pusher; 3 - brake pedal; 4 – the buffer of the stoplight switch; 5 - switch nut; 6 - stoplight switch; 7 - pedal retract spring The free travel...

Brake pedal 1 – main cylinder; 2 - pusher; 3 - brake pedal; 4 – the buffer of the stoplight switch; 5 - switch nut; 6 - stoplight switch; 7 - pedal retract spring The free travel...

Parking brake adjustment

Parking brake actuator 1 - front cable; 2 - rear cable guide; 3 - retracting spring of the front cable; 4 - locknut; 5 - adjusting nut; 6 - spacer sleeve If the parking brake does...

Parking brake actuator 1 - front cable; 2 - rear cable guide; 3 - retracting spring of the front cable; 4 - locknut; 5 - adjusting nut; 6 - spacer sleeve If the parking brake does...

Checking the performance of the pressure regulator

1. Place the vehicle on a lift or inspection ditch, clean the pressure regulator and protective cover from dirt. 2. Carefully remove the protective cover from the pressure...

1. Place the vehicle on a lift or inspection ditch, clean the pressure regulator and protective cover from dirt. 2. Carefully remove the protective cover from the pressure...

Adjusting the position of the pressure regulator

Installation diagram of the rear brake pressure regulator and its adjustment 1, 2 - bolts for fastening the regulator to the bracket; 3 - protective cap; 4 – torsion lever of the...

Installation diagram of the rear brake pressure regulator and its adjustment 1, 2 - bolts for fastening the regulator to the bracket; 3 - protective cap; 4 – torsion lever of the...

Removal of air from a hydraulic drive of brakes

The air that got into the brake hydraulic drive when replacing the pipeline, hoses, sealing rings or system leaks causes an increase in the brake pedal stroke, its «softness» and...

The air that got into the brake hydraulic drive when replacing the pipeline, hoses, sealing rings or system leaks causes an increase in the brake pedal stroke, its «softness» and...

Adjustment of a backlash between pads and a drum

Scheme for adjusting the clearance between the pads and the brake drum A - adjusting eccentrics of the front pads; B - adjusting eccentrics of the rear pads; S - left wheel; d -...

Scheme for adjusting the clearance between the pads and the brake drum A - adjusting eccentrics of the front pads; B - adjusting eccentrics of the rear pads; S - left wheel; d -...

Clutch and brake pedal bracket — removal and installation

1. Remove the steering shaft bracket as directed in subsection 9.3.1 . 2. Disconnect the nuts securing the clutch master cylinder and brake master cylinder to the bracket. 3....

1. Remove the steering shaft bracket as directed in subsection 9.3.1 . 2. Disconnect the nuts securing the clutch master cylinder and brake master cylinder to the bracket. 3....

Clutch and brake pedal bracket — disassembly and assembly

Clutch and brake pedal bracket parts 1 - pedal bracket; 2 - nuts; 3 - spring washer; 4 – the internal plug of a pedal of a brake; 5 - outer bushings of the brake pedal; 6 – brake...

Clutch and brake pedal bracket parts 1 - pedal bracket; 2 - nuts; 3 - spring washer; 4 – the internal plug of a pedal of a brake; 5 - outer bushings of the brake pedal; 6 – brake...

Clutch and brake pedal bracket — check and repair

If the pedals are hard to move, inspect the working surfaces of the pedals, bushings and axles. If shallow scratches or traces of oxidation are found on the surfaces of metal...

If the pedals are hard to move, inspect the working surfaces of the pedals, bushings and axles. If shallow scratches or traces of oxidation are found on the surfaces of metal...

Master brake cylinder — removal and installation

1. Disconnect the flexible hoses from the master cylinder and cover the hoses and fittings on the cylinder to prevent leakage of fluid from the reservoir and entry of dust, dirt...

1. Disconnect the flexible hoses from the master cylinder and cover the hoses and fittings on the cylinder to prevent leakage of fluid from the reservoir and entry of dust, dirt...

Master brake cylinder — disassembly and assembly

Hydraulic brake master cylinder 1 - cork; 2 - cylinder body; 3 – the piston of a drive of back brakes; 4 - washer; 5 – the piston of a drive of forward brakes; 6 - sealing ring; 7...

Hydraulic brake master cylinder 1 - cork; 2 - cylinder body; 3 – the piston of a drive of back brakes; 4 - washer; 5 – the piston of a drive of forward brakes; 6 - sealing ring; 7...

Brake Master Cylinder — Parts Check

Before assembly, wash all parts with isopropyl alcohol; dry them with compressed air or wipe with a clean cloth, avoiding contact with mineral oil, kerosene or diesel fuel, which...

Before assembly, wash all parts with isopropyl alcohol; dry them with compressed air or wipe with a clean cloth, avoiding contact with mineral oil, kerosene or diesel fuel, which...

Check of tightness of the main brake cylinder

Master Cylinder Leak Test Diagram 1 - valve for pumping; 2 - manometer; 3 – absorbing cylinder; 4 - main cylinder; 5 - flywheel; 6 - pusher displacement indicator; 7 - crane; 8 -...

Master Cylinder Leak Test Diagram 1 - valve for pumping; 2 - manometer; 3 – absorbing cylinder; 4 - main cylinder; 5 - flywheel; 6 - pusher displacement indicator; 7 - crane; 8 -...

Front brakes — removal and installation

Before repairing the brakes, wash them thoroughly with warm water and detergent and dry immediately with compressed air. Warning! The use of gasoline, diesel fuel,...

Before repairing the brakes, wash them thoroughly with warm water and detergent and dry immediately with compressed air. Warning! The use of gasoline, diesel fuel,...

Front brakes — disassembly and assembly

Front wheel brake caliper parts 1 - piston; 2 - dust cap; 3 - sealing ring; 4 – support with cylinders; 5 – a connecting tube of brake cylinders; 6 - air outlet fitting; 7 -...

Front wheel brake caliper parts 1 - piston; 2 - dust cap; 3 - sealing ring; 4 – support with cylinders; 5 – a connecting tube of brake cylinders; 6 - air outlet fitting; 7 -...

Front brakes — checking details

Carefully check all parts by first washing them with warm water and detergent and drying them with a jet of compressed air. If, during the check, signs of wear or seizure are...

Carefully check all parts by first washing them with warm water and detergent and drying them with a jet of compressed air. If, during the check, signs of wear or seizure are...

Front brake disc runout check

Checking the axial runout of the brake disc 1 - magnetic stand; 2 - indicator; 3 - brake disc Check the axial play of the brake disc without removing it from the vehicle. The...

Checking the axial runout of the brake disc 1 - magnetic stand; 2 - indicator; 3 - brake disc Check the axial play of the brake disc without removing it from the vehicle. The...

Replacing the front brake pads

Replace the pads with new ones if the thickness of the pads has decreased to 1.5 mm. 1. Remove cotter pins 14 (see fig. Front wheel brake ) and fingers 8 with springs. Then remove...

Replace the pads with new ones if the thickness of the pads has decreased to 1.5 mm. 1. Remove cotter pins 14 (see fig. Front wheel brake ) and fingers 8 with springs. Then remove...

Rear brakes — removal and disassembly

Rear wheel brake 1 – wheel cylinder; 2 – the lever of a manual drive of pads; 3 – block of a brake; 4 – a cup and a basic rack of pads; 5 – a cable of a drive of a lay brake with...

Rear wheel brake 1 – wheel cylinder; 2 – the lever of a manual drive of pads; 3 – block of a brake; 4 – a cup and a basic rack of pads; 5 – a cable of a drive of a lay brake with...

Rear brakes — assembly and installation

1. Install and fix the wheel cylinder on the brake shield, attach the brake fluid supply pipe to it and tighten the union nut to the full. 2. Attach the lever 2 of the manual...

1. Install and fix the wheel cylinder on the brake shield, attach the brake fluid supply pipe to it and tighten the union nut to the full. 2. Attach the lever 2 of the manual...

Rear brakes — checking details

Wheel cylinder parts 1 - protective cap; 2 - piston; 3 - sealant; 4 – the case of the wheel cylinder; 5 - spring cups; 6 - air outlet fitting; 7 - spring; Wheel cylinders 1. To...

Wheel cylinder parts 1 - protective cap; 2 - piston; 3 - sealant; 4 – the case of the wheel cylinder; 5 - spring cups; 6 - air outlet fitting; 7 - spring; Wheel cylinders 1. To...

Checking the wheel cylinders of the rear brakes on the stand

Scheme for checking the wheel cylinders of the rear brakes 1 - piston stops; 2 – tested cylinder; 3 - cylinder bracket; 4 - low pressure manometer; 5 – high pressure manometer; 6...

Scheme for checking the wheel cylinders of the rear brakes 1 - piston stops; 2 – tested cylinder; 3 - cylinder bracket; 4 - low pressure manometer; 5 – high pressure manometer; 6...

Rear brake pressure regulator — removal and installation

Pressure Regulator Drive Parts 1 - pressure regulator; 2 – axis of the regulator drive lever; 3 - dirt cap; 4 - locking plate; 5 - bolt with spring washer; 6 - rear axle; 7 –...

Pressure Regulator Drive Parts 1 - pressure regulator; 2 – axis of the regulator drive lever; 3 - dirt cap; 4 - locking plate; 5 - bolt with spring washer; 6 - rear axle; 7 –...

Rear brake pressure regulator — disassembly and assembly

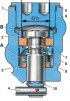

Rear brake pressure regulator in non-working position A - normal pressure cavity; В – cavity of regulated pressure; P is the force transmitted by lever 4 of the regulator drive; 1...

Rear brake pressure regulator in non-working position A - normal pressure cavity; В – cavity of regulated pressure; P is the force transmitted by lever 4 of the regulator drive; 1...

Rear Brake Pressure Regulator — Parts Check

1. Wash the parts with alcohol or brake fluid and inspect. The surfaces of the parts should not have scratches and roughness. 2. Check the condition and elasticity of the spring,...

1. Wash the parts with alcohol or brake fluid and inspect. The surfaces of the parts should not have scratches and roughness. 2. Check the condition and elasticity of the spring,...

Parking brake — removal and installation

Parking brake drive parts 1 - cover; 2 - front cable; 3 - lever; 4 - button; 5 - thrust spring; 6 - latch rod; 7 - bushing; 8 - roller; 9 - rear cable guide; 10 - spacer sleeve;...

Parking brake drive parts 1 - cover; 2 - front cable; 3 - lever; 4 - button; 5 - thrust spring; 6 - latch rod; 7 - bushing; 8 - roller; 9 - rear cable guide; 10 - spacer sleeve;...

Parking brake — check and repair

1. Carefully check the condition of the parking brake parts. 2. If a break or rubbing of the wires is detected, replace the cable with a new one. 3. Make sure that the teeth of...

1. Carefully check the condition of the parking brake parts. 2. If a break or rubbing of the wires is detected, replace the cable with a new one. 3. Make sure that the teeth of...

Possible malfunctions of the brakes, their causes and methods of elimination

Cause Elimination Method Insufficient braking performance Leakage of brake fluid from the wheel cylinders of the front or rear brakes Replace bad parts of wheel cylinders, wash...

Cause Elimination Method Insufficient braking performance Leakage of brake fluid from the wheel cylinders of the front or rear brakes Replace bad parts of wheel cylinders, wash...

This section is available on russian, bulgarian, belarusian, ukrainian, serbian, croatian, romanian, polish, slovak, hungarian

More articles from other manuals on VAZ cars:

➠ Chassis: Brake system VAZ-1111 (1988-1996)

➠ Chassis: Brake system VAZ-21051 (1979-2010)

➠ Chassis: Brake system VAZ-21061 (1976-2006)

➠ Chassis: Brake system VAZ-2107 (1982-2012)

➠ Chassis: Brake system VAZ-2108 (1984-2003)

➠ Chassis: Brake system VAZ-2110 (1995-2007)

➠ Chassis: Brake system VAZ-2114 (2004-2013)

➠ Chassis: Brake system VAZ-2121 (1977-1994)

➠ Chassis: Brake system VAZ-1111 (1988-1996)

➠ Chassis: Brake system VAZ-21051 (1979-2010)

➠ Chassis: Brake system VAZ-21061 (1976-2006)

➠ Chassis: Brake system VAZ-2107 (1982-2012)

➠ Chassis: Brake system VAZ-2108 (1984-2003)

➠ Chassis: Brake system VAZ-2110 (1995-2007)

➠ Chassis: Brake system VAZ-2114 (2004-2013)

➠ Chassis: Brake system VAZ-2121 (1977-1994)

Share with friends:

- General information

- Vehicle description

- Vehicle device

- Vehicle operation

- Maintenance

- Main malfunctions

- Applications

- Power unit

- Engine repair

- Cooling and lubrication system

- Supply system

- Transmission

- Clutch

- Transmission

- Cardan gear

- Rear axle

- Chassis

- Front suspension

- Rear suspension

- Steering

- Brake system

- Body

- Exterior

- Interior

- Electrical equipment

- Engine electrics

- Equipment and devices

- General information

- Specifications

- Operation and maintenance

- Power unit

- Engine repair

- Cooling system

- Lubrication system

- Power and exhaust system

- Ignition system

- Engine electrics

- Transmission

- Clutch

- Car gearbox

- Cardan gear

- Rear axle

- Chassis

- Car suspension

- Steering

- Brake system

- Body

- Exterior

- Interior

- Doors and locks

- Electrical equipment

- Equipment and devices

- Lighting and signaling

VAZbook.ru © 2017 · Mobile version · Contact with administration · Sitemap: EN BG BY UA RS HR RO PL SK HU · Site search · News and articles

VAZ-1111 · VAZ-11113 · VAZ-2101 · VAZ-21011 · VAZ-2104 · VAZ-2105 · VAZ-21051 · VAZ-2106 · VAZ-21061 · VAZ-2107 · VAZ-21099 · VAZ-2109 · VAZ-2108 · VAZ-2110 · VAZ-2112 · VAZ-2114 · VAZ-2115 · VAZ-2121 · VAZ-21213 · VAZ-21214 ·