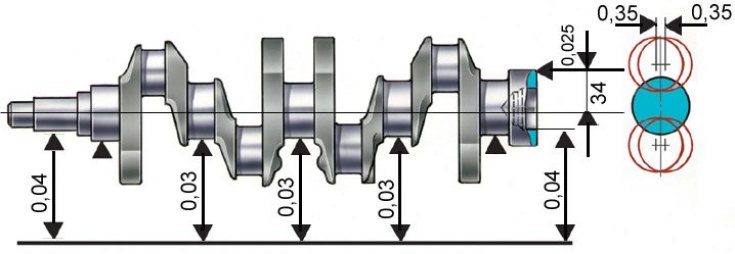

Permissible runout of the main surfaces of the crankshaft

Examination

1. Install the crankshaft on two prisms (see fig. Permissible runout of the main surfaces of the crankshaft) and check with the indicator:

- beating of the main journals (maximum allowable 0.03 mm);

- runout of seating surfaces under the sprocket and gearbox input shaft bearing (maximum allowable 0.04 mm);

- displacement of the axes of the connecting rod journals from the plane passing through the axes of the connecting rod and main journals (maximum allowable±0.35 mm);

- non-perpendicularity with respect to the axis of the crankshaft of the end surface of the flange. When turning the shaft, an indicator mounted on the side at a distance of 34 mm (see fig. Permissible runout of the main surfaces of the crankshaft) from the shaft axis, should not show runouts of more than 0.025 mm.

2. Cracks are not allowed on the main, connecting rod journals and on the cheeks of the crankshaft. If they are found, replace the shaft.

3. On the surfaces of the crankshaft, mating with the working edges of the seals, scratches, nicks and risks are not allowed.

4. Measure the diameters of the main and connecting rod journals. The necks should be ground if their wear is more than 0.03 mm or the ovality of the necks is more than 0.03 mm, and also if there are scratches and marks on the necks.

Neck grinding

1. Grind main and connecting rod journals, reducing by 0.25 mm so as to obtain, depending on the degree of wear, diameters corresponding to the values given in Table. Diameters of connecting rod journals, mm and tab. The diameters of the main journals, mm, and the radii of the neck fillets, as shown in fig. The main dimensions of the connecting rod and main journals of the crankshaft and their fillets.

2. After grinding and subsequent finishing of the necks, rinse the crankshaft well to remove abrasive residues. Flush lubrication channels with removed plugs several times with gasoline under pressure. On the first cheek of the crankshaft, mark the amount of reduction of the main and connecting rod journals (e.g. K 0.25, W 0.50).

3. The ovality and taper of the main and connecting rod journals after grinding should be no more than 0.007 mm.

Diameters of connecting rod journals, mm

Rated | reduced | |||

0,25 | 0,50 | 0,75 | 1,0 | |

47,814 | 47,564 | 47,314 | 47,064 | 46,814 |

47,834 | 47,584 | 47,334 | 47,084 | 46,834 |

Diameters of main journals, mm

Rated | reduced | |||

0,25 | 0,50 | 0,75 | 1,0 | |

50,775 | 50,525 | 50,275 | 50,025 | 49,775 |

50,795 | 50,545 | 50,295 | 50,045 | 49,795 |