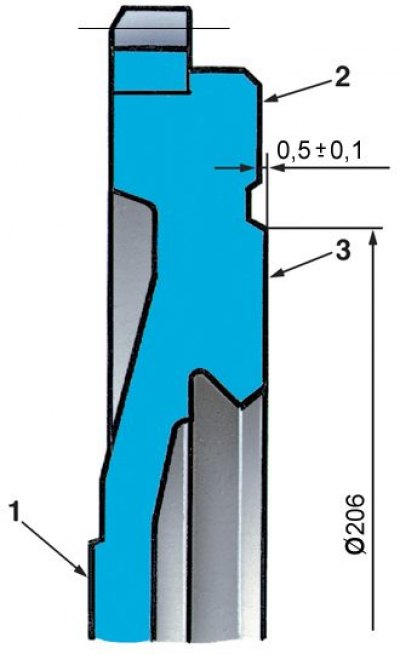

Flywheel

1 - mounting surface to the crankshaft flange; 2 – a surface of fastening of coupling; 3 – a basic surface of a conducted disk of coupling

1. Check the condition of the ring gear; If the teeth are damaged, replace the flywheel.

2. The surfaces of the flywheel mating with the crankshaft and with the clutch disc must be free from scratches, burrs and be perfectly flat.

3. If there are scratches on the working surface 3 of the flywheel under the clutch disc, grind this surface, removing a layer of metal no more than 1 mm thick. Then machine surface 2, maintaining a dimension of 0.5±0.1 mm and ensuring the parallelism of surfaces 2 and 3 relative to surface 1. The non-parallelism tolerance is 0.1 mm.

4. Install the flywheel on the mandrel, centering it on the mounting hole with an emphasis on surface 1, check the runout of planes 3 and 2.

5. At the extreme points, the indicator should not show beats exceeding 0.1 mm.