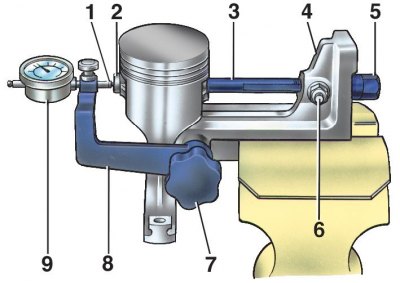

Piston-pin-connecting rod assembly assembled on tool A.95615 for pin extrusion test

1 - indicator pin in contact with the end of the rod; 2 - the head of the rod in contact with the finger; 3 - threaded rod with a groove; 5 - rod nut; 6 - thrust pin of the rod; 7 – arm clamp handle; 8 – indicator bracket; 9 - indicator

The strength of the pin is checked after assembling the connecting rod-pin-piston group using a torque wrench and tool A.95615.

1. Clamp base 4 (see fig. Assembled piston-pin-connecting rod assembly mounted on fixture A.95615 for pin extrusion test) fixtures in a vise and install the connecting rod and piston group on it.

2. Lower the bracket 8 of the indicator, insert the threaded rod 3 into the hole of the pin and slide it into the hole of the boss until the head 2 of the rod rests against the end of the pin.

3. Screw nut 5 onto the end of the rod and tighten it so that it, in contact with the support, selects possible gaps.

4. Raise the bracket 8 to a horizontal position, secure it with the handle 7 and install the pin 1 of the indicator 9 on the head 2 of the rod inserted into the pin.

5. Set the indicator to zero and insert stop 6 into the groove of the threaded rod so that the rod does not turn.

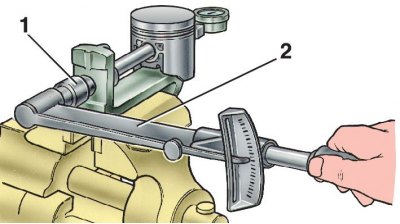

6. Using a torque wrench 2, tighten the nut 1 of the rod, applying a torque of 12.7 N·m to it (1.3 kgf·m), which corresponds to an axial load of 3.92 kN (400 kgf).

7. The landing of the finger in the connecting rod will be correct if, after the termination of the torque wrench and the return of the nut to its original position, the indicator needle returns to zero.

8. If the pin slips in the upper head of the connecting rod, replace the connecting rod with a new one.