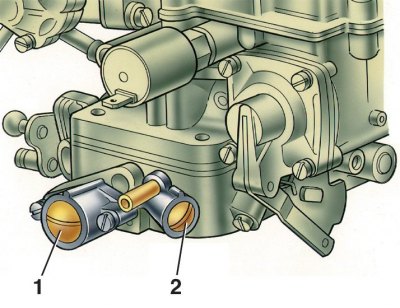

Carburetor idle adjustment screws

1 – mixture quantity screw; 2 - composition screw (quality) mixtures

Elements for adjusting the idle speed of the engine include screw 2, which determines the composition of the mixture, and screw 1, which regulates the amount of the mixture. To prevent the owner from violating the factory adjustment, restrictive plastic bushings are pressed onto screws 1 and 2, allowing you to turn the screws only half a turn. If it is not possible to adjust the CO content in the exhaust gases with the bushings, then by unscrewing the screws, break the heads of the bushings, unscrew the screws, remove the bushings from them and screw the screws into the carburetor again.

Attention! Blue bushings are installed at the factory, and red bushings at service stations.

Adjust the idle speed on a warm engine (coolant temperature 90–95°С and oil 75–90°С) with adjusted gaps in the gas distribution mechanism and with a correctly set ignition timing.

1. Use screw 1 to set the crankshaft speed to 820–900 min using the stand tachometer-1.

2. Screw 2 achieve concentration (reduced to 20°С and 1013 GPa (760 mmHg Art.)) CO in the exhaust gases within 0.5–1.2% at a given position of screw 1.

3. Screw 1 restore the crankshaft speed to 820-900 min-1.

4. If necessary, use screw 2 to restore the CO concentration to 0.5–1.2%.

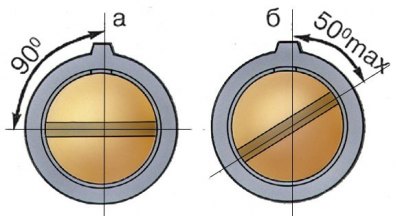

5. Press restrictive plastic bushings onto the screws, orienting the splines of the bushings relative to the mounting tabs, as shown in the figure.