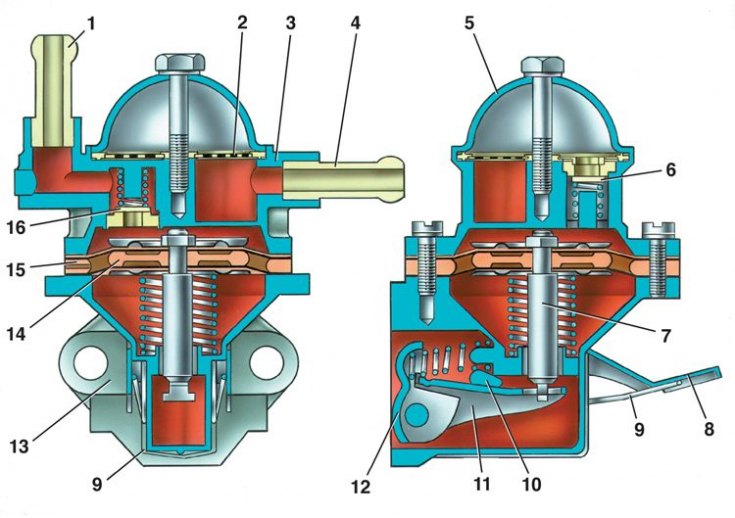

Fuel pump

1 - discharge pipe; 2 - filter; 3 - body; 4 - suction pipe; 5 - cover; 6 - suction valve; 7 - pusher; 8 – manual fuel pumping lever; 9 - spring; 10 - cam; 11 - balancer; 12 – mechanical fuel pumping lever; 13 - bottom cover; 14 – internal spacer; 15 - outer spacer; 16 - discharge valve

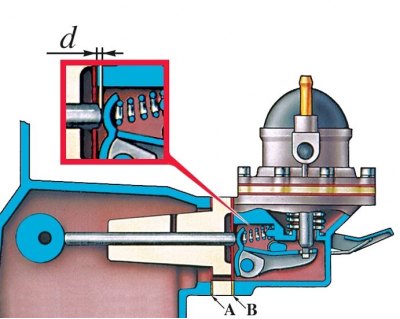

Scheme for monitoring and adjusting the protrusion of the pusher of the pump drive

A - gasket 0.27–0.33 mm thick; B - gasket 0.70–0.80 mm thick; d - protrusion of the pusher

The fuel pump device is shown in fig. Fuel pump.

Examination

Insufficient filling of the carburetor with gasoline may be due to a malfunction of the fuel pump, as well as clogging or damage to the pipelines.

To find the cause of the malfunction, disconnect the hose from the discharge pipe 1 and use the manual fuel priming lever 8 to check whether fuel is supplied. If there is no fuel, then disconnect the hose from the suction pipe 4 and check whether a vacuum is created at the outlet of this pipe. If there is a vacuum, then the pipeline is faulty, and if not, then the pump is faulty.

Dismantling, cleaning and checking parts

1. To disassemble the pump, unscrew the cover fastening bolt 5, remove the cover and filter 2. Then unscrew the screws securing the housing to the bottom cover, separate them, remove the diaphragm assembly and the spring.

2. Rinse all parts with gasoline and blow with compressed air.

3. Check the integrity of the pump springs.

4. Check for valve sticking. Check the condition of the diaphragms. They should not be cracked or hardened.

5. After checking, replace any worn or damaged parts with new ones. Always replace pump gaskets with new ones and lubricate with a thin layer of grease before installation.

Installation

The pump installation diagram is shown in fig. Scheme for monitoring and adjusting the protrusion of the pusher of the pump drive.

1. For the correct installation of the fuel pump, use two of the three gaskets: A - 0.27–0.33 mm thick; B - 0.70–0.80 mm thick; C - 1.10–1.30 mm thick.

2. Install the heat-insulating spacer on the cylinder block, placing gasket A between them, and place gasket B on the plane mating with the pump. Using tool 67.7834.9506, measure the distance d (the minimum amount that the pushrod protrudes, set by slowly turning the crankshaft). If the dimension d is in the range of 0.8-1.3 mm, then fix the pump to the engine. If d is less than 0.8 mm, replace gasket B with gasket A; if more than 1.3 mm, replace gasket B with gasket C. Check dimension d again and mount the pump on the motor.

3. There must always be a gasket A between the cylinder block and the heat-insulating spacer.