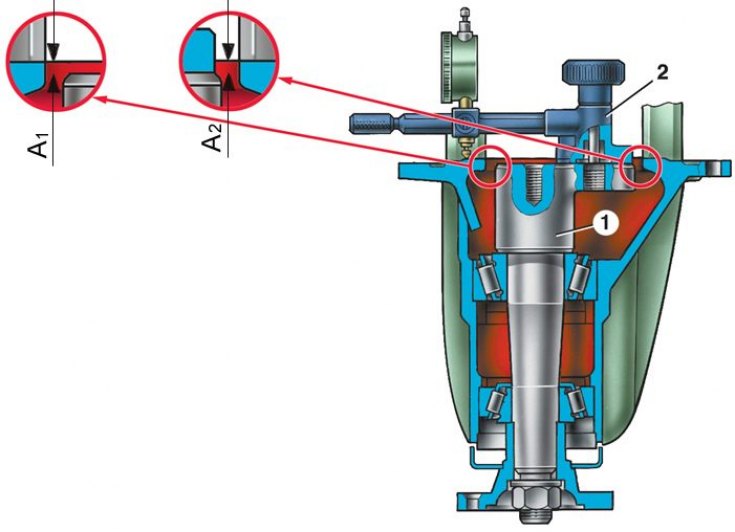

Scheme of taking measurements to determine the thickness of the adjusting ring of the drive gear

1 - mandrel A.70184; 2 - fixture A.95690 with an indicator; a1 and a2 - the distance from the end of the mandrel to the necks of the differential bearings

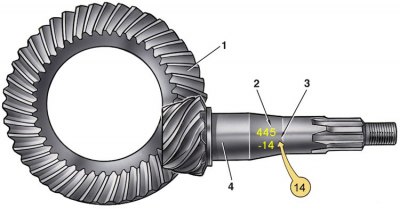

Final drive gears

1 - driven gear; 2 - serial number; 3 - correction in hundredths of a millimeter to the nominal position; 4 - drive gear

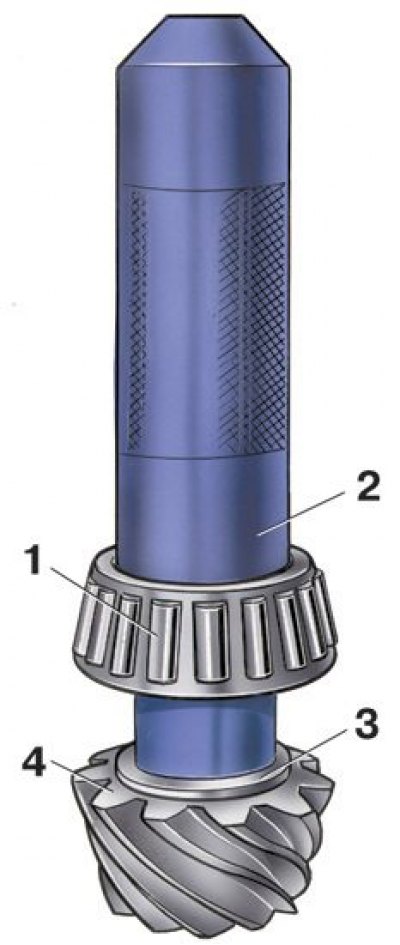

Installing the rear bearing inner race on the drive gear

1 - the inner ring of the rear roller bearing; 2 - mandrel A.70152; 3 - adjusting ring; 4 - drive gear

1. The correct position of the drive gear relative to the driven gear is ensured by selecting the thickness of the adjusting ring installed between the stop end of the drive gear and the inner ring of the rear bearing.

2. Select the adjusting ring using the mandrel A.70184 and tool A.95690 with indicator. Carry out operations in the following order.

3. Having fixed the crankcase on the stand, press the outer rings of the front and rear bearings of the drive gear into the housings of the crankcase, using mandrels for this: for the front bearing - A.70185, and for the rear - A.70171 (1 - mandrel А.70171).

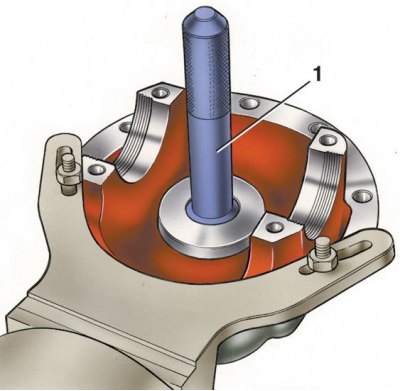

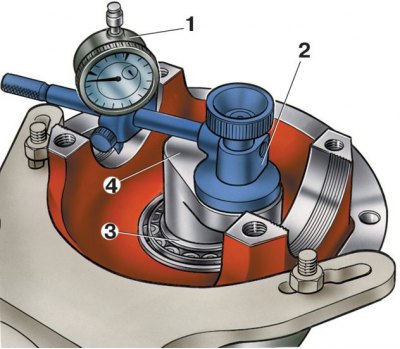

4. On mandrel A.70184, simulating the drive gear, use mandrel A.70152 to install the inner ring of the rear bearing and insert the mandrel into the neck of the gearbox housing (1 - indicator; 2 - fixture A.95690; 3 - rear bearing of the drive gear; 4 - mandrel А.70184).

5. Install the inner ring of the front bearing, the drive gear flange and, turning the mandrel to properly install the bearing rollers, tighten the nut to a torque of 7.84–9.8 N·m (0.8–1 kgf·m).

6. Fix fixture A.95690 on the end of mandrel 4 and adjust the indicator, which has divisions of 0.01 mm, to the zero position by placing its leg on the same end of mandrel A.70184. Then move indicator 1 so that its leg rests on the seating surface of the differential box bearing.

7. Turning mandrel 4 with indicator to the left and right, set it to a position where the indicator arrow marks the minimum value «a1» (see fig. Scheme of taking measurements to determine the thickness of the adjusting ring of the drive gear) and write it down.

8. Repeat this operation on the seat of the second bearing and determine the value «a2».

9. Determine thickness «S» adjusting ring of the drive gear, which is the algebraic difference between the values «A» and «b»: S \u003d a - b, where a is the arithmetic mean distance from the end of the mandrel 1 (see fig. Scheme of taking measurements to determine the thickness of the adjusting ring of the drive gear) to the necks of the differential bearings a = (a1 + a2) /2, b - deviation of the drive gear from the nominal position, translated in mm. The amount of deviation is marked on the drive gear (see fig. final drive gears) in hundredths of a millimeter with a plus or minus sign.

10. When determining the thickness of the adjusting ring, consider the sign of the value «b» and its unit of measurement.

Example:

Let's assume that the value «A», set using the indicator, is equal to 2.91 mm (magnitude «A» always positive), and on the drive gear after the serial number the deviation is set «-14». To get the value «b» in millimeters, you need to multiply the indicated value by 0.01 mm:

b = -14 x 0.01 mm = - 0.14 mm.

Determine the thickness of the adjusting ring for the pinion in millimeters:

S = a - b = 2.91 mm - (- 0.14 mm) = 2.91 mm + 0.14 mm = 3.05 mm.

In this case, install a 3.05 mm thick adjusting ring.

11. Put an adjusting ring of the required thickness on the drive gear and press on with mandrel A.70152 (see fig. Installing the rear bearing inner race on the drive gear) rear bearing inner race removed from mandrel A.70184. Put on the spacer sleeve.

Attention! When repairing the rear axle gearbox, a new spacer must be installed if the gearbox housing, final drive gears or pinion bearings have been replaced. If the specified parts remain the same, the spacer sleeve can still be used.

12. Insert the drive gear into the gear housing and install the front bearing inner race, oil slinger, oil seal, drive gear flange and washer onto it.

Attention! In order not to damage the oil seal during pressing, it is necessary to press it not to the stop, but to a depth of 2 mm (tolerance «-0,3») between the end face of the gearbox housing and the outer surface of the stuffing box.

13. Screw a nut onto the end of the drive gear and, locking the flange of the drive gear, tighten it (For tightening torque, see below)