To carry out the work, you will need a carburetor cleaner or acetone.

Disassembly

1. Remove the carburetor (see "Carburetor - removal and installation").

2. Disconnect the carburetor cover from the body (see "Carburetor cover - removal and disassembly").

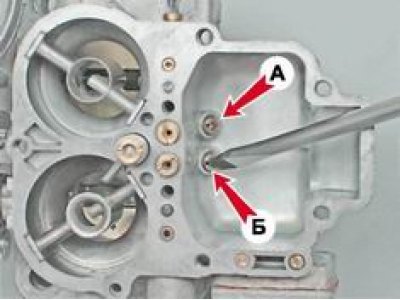

3. Using a slotted screwdriver, unscrew the main fuel jet A of the secondary chamber with the marking "150" and the main fuel jet B of the primary chamber marked "112".

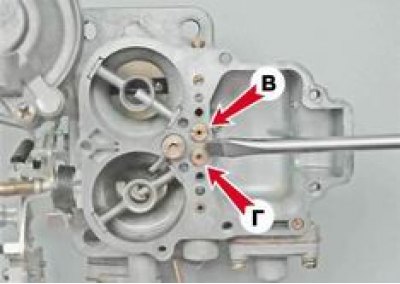

4. Using the same tool, turn out the main air jet B of the secondary chamber marked "130" and the main air jet D of the primary chamber with the marking "150".

5. Emulsion tubes are installed under the air jets in the wells. Prying with a suitable tool, we remove them from the wells. For this operation, you can use a needle file with a tapering working surface.

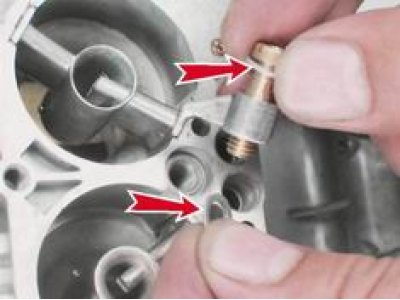

6. Using a slotted screwdriver, unscrew the screw valve of the accelerator pump.

7. Remove the valve with the accelerator pump atomizer and the sealing ring. Prying with a thin screwdriver, remove the lower sealing ring from the hole.

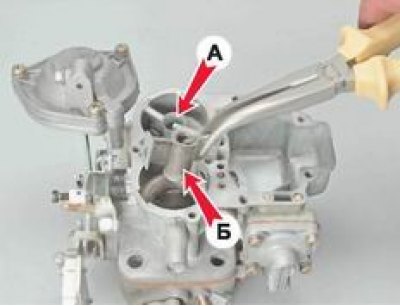

8. Using pliers, remove the small diffusers of the primary B and secondary A chambers. Primary chamber diffuser marking - 3.5 (35), secondary - 4.5 (45).

If the diffusers are not removed after removing the throttle body (see below) knock them out from the opposite side with a soft metal drift.

9. With a slotted screwdriver with a blade width of not more than 3 mm, unscrew the accelerator pump screw and remove it from the channel.

10. Using a slotted screwdriver, unscrew the body of the fuel jet of the transition system of the secondary chamber.

11. We take out the housing with the jet from the channel.

12. Remove jet B from body A.

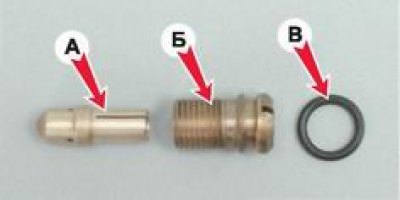

13. With a slotted screwdriver, we unscrew the housing of the fuel jet of the idle system.

14. We remove the body with the jet from the channel opening.

15. We take out the jet A from the housing B and, prying with a screwdriver, remove the rubber sealing ring B from the housing.

A damaged ring must be replaced.

16. Using a Phillips screwdriver, unscrew the four screws securing the accelerator pump diaphragm cover.

17. Remove the cover, remove the spring and disconnect the diaphragm.

18. Disconnect with pliers and remove the return spring.

19. Disconnect the throttle actuator (see "Pneumatic throttle valve - removal and installation").

20. Using a Phillips screwdriver, unscrew the two screws securing the throttle body to the carburetor body.

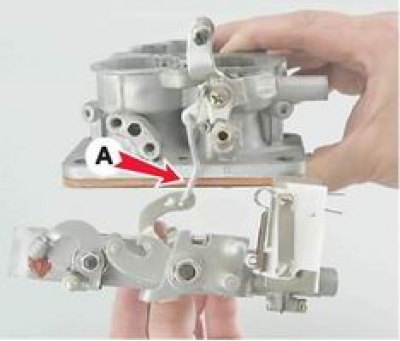

21. Disconnect the housings by disengaging the rod A from the lever.

22. Carefully remove the heat-insulating spacer with two cardboard spacers.

23. Remove the microswitch with bracket and economizer (see "Forced idle economizer [EPHH] - check and replace").

24. Using a slotted screwdriver, we unscrew and remove the quality screw with a rubber sealing ring. For the convenience of subsequent installation, remember the number of revolutions of the screw.

Note If a restrictive sleeve is installed on the screw, use a slotted screwdriver to turn the sleeve until it is destroyed and remove its parts from the hole.

Assembly

1. Before assembly, we wash the carburetor parts with a cleaner or acetone. We blow out the fuel and air channels with compressed air. We check the condition of the gaskets: gaps and cracks on them are not allowed. If necessary, replace the gaskets with new ones. When assembling, lubricate all rubber o-rings with engine oil. The assembly of the carburetor body is carried out in the reverse order.

2. We install previously removed parts in the reverse order.