Removal and disassembly

To remove the pendulum arm bracket, disconnect the pendulum arm from the ball pins of the middle and side right rods by unpinning and unscrewing the nuts beforehand and removing the ball pins from the lever sockets with a puller A.47052. Then turn away bolts of fastening of an arm to a side member and remove it.

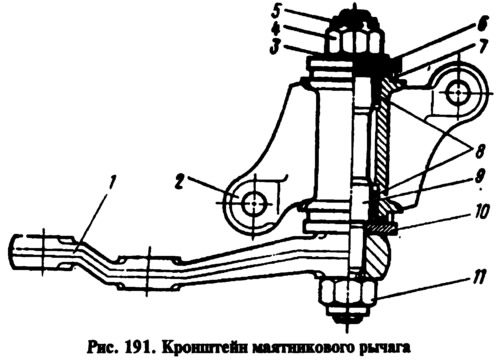

For disassembly, fix bracket 2 (pic. 191) in a vice, remove cotter pin 5 and unscrew nut 4, then remove washers 3 and 6, pendulum arm 1 complete with axle 9, washer 10 and self-locking nut 11, then remove seals 7 and press out bushings 8.

Examination

After disassembly, check the condition of the pendulum arm axle bushings and its axle. Replace if oval or damaged. In addition, check if the pendulum arm is deformed, otherwise replace it as well.

Assembly and installation

Before assembly, lubricate the pendulum arm axle bushings and fill the space between them with Litol-24 grease. The assembly procedure for the pendulum arm bracket is the reverse of disassembly. In this case, if the axle 9 was replaced, then tighten the self-locking nut 11 of the lever fastening with a torque wrench. Install the washer 6 with the projections up. After tightening the nut 4, the lever in the horizontal position must not rotate under its own weight. It should rotate under the action of a force of 1-2 kgf applied at its end. If nut 4 is overtightened, unscrew it, lift washer 6 and tighten again.

After that, fasten the bracket to the body side member with bolts with self-locking nuts and flat washers and connect the ball pins of the rods to the pendulum lever.