Deformation of the lower arm is determined by inspection

Check the deformation of the front suspension cross member in the following sequence:

- unscrew nuts of fastening of axes 35 (see fig. 156) lower levers so that in the resulting gap between the washer 28 and the mating surface of the cross member 30, the leg of the caliper fits close to the bolt shaft;

- measure the length of the cross member between the planes of the axes of the lower arms (left and right) in the area of the front bolts. The distance should be 611±1 mm. Change the cross member if it is deformed so that the wheel alignment angles cannot be adjusted.

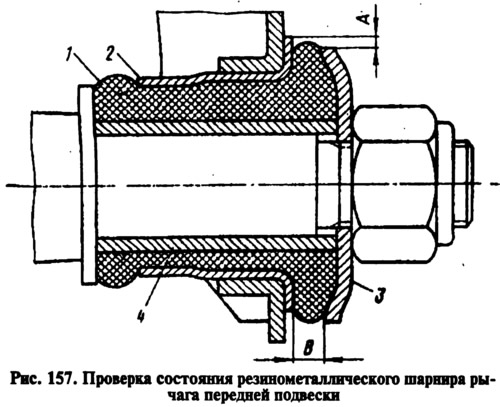

Condition of rubber-metal hinges

Check the condition of rubber-metal hinges in the following order:

- after making sure that there is no deformation of the suspension arms, the axis of the lower arm, hang the front wheels of the car;

- measure radial displacement A (pic. 157) outer bushing 2 relative to the inner bushing 4 and the distance B between thrust washer 3 and the outer end of the outer bushing 2. Replace rubber-metal joints if it is impossible to adjust the camber (when all washers are removed from under the axis of the lower arm), at breaks and unilateral «buckling» rubber 1, with a radial displacement A of more than 2.5 mm and if the dimension B does not fit within 3-7.5 mm for the lower lever and 1.5-5 mm for the upper. If dimension B is outside the specified limits, check that the rubber-metal joint is correctly pressed into the lever socket.

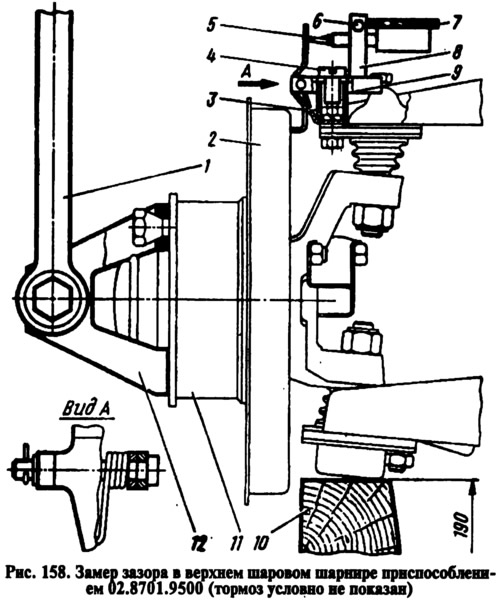

Clearance in upper ball joints

Check the clearance in the upper ball joints using tool 02.8701.9500. To do this, park the vehicle on a level, hard surface, raise the front of the vehicle and remove the wheel. Substitute a wooden block under the lower ball joint 10 (pic. 158) 190 mm high and lower the vehicle onto it. Install the bushing 9 on the nut of the upper hinge fastening bolt closest to the casing, then put the base 8 on the bushing and lightly fasten it with the screw 4. By moving the device, set the lever 3 to the vertical position so that its lower end rests against the protective casing 2 of the brake, and tighten screw 4. Install the indicator 7 into the base post 8 until its legs 5 stop against the lever 3 with an interference of 2-3 mm and tighten the bolt 6. Attach the bracket to the hub 11 with two bolts, put the torque wrench 1 on the hex head of the bracket axis 12 and torque 20 kgfm turn the key to and from the vehicle. Sum up both indicators. The amount should not exceed 0.8 mm.

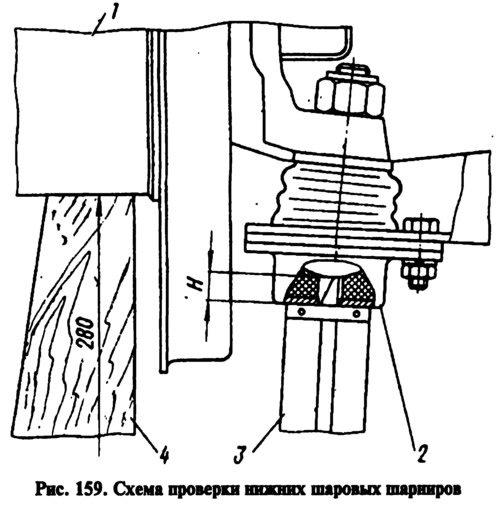

Condition of the lower ball joints

Check the condition of the lower ball joints in the following order:

- park the car on a flat, hard surface and raise the front of the car, then remove the wheel;

- put under hub 1 (pic. 159) wooden block 4 280 mm high and lower the car onto it;

- clean the lower part of the hinge 2 from dust and dirt and unscrew the conical plug;

- measure the distance H with a caliper depth gauge 3. If H > 11.3 mm, then remove the hinge from the car and carefully inspect. There should be no cracks on the hinge body, and dirt in the grease. If there is dirt in the grease, cracks in the body, and if H > 11.8 mm, replace the joint.

Check the condition of the body front elements as indicated in the section «Body».