* Glass ∅ 48 mm with a beveled bottom, in which a radial groove 17 mm wide is made. A M22x1.5 screw is screwed into the glass.

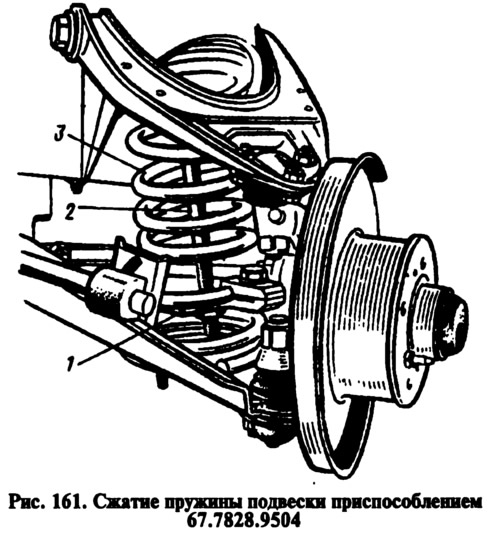

Insert screw 2 (pic. 161) accessories 67.7828.9504 (pic. 162) into the hole of the upper support of the suspension spring, put it on the coil of the spring from below 3 (see fig. 161) and on the screw 2 support plate 1 and fix it on the spring with a clamp. Screw the nut onto the screw from below so that its retainer fits into the socket of the plate 1. Turning the screw 2 with a wrench, compress the spring until the suspension arms are completely unloaded. Take out an axis of the top lever and disconnect it from a body. Disconnect the lower arm axle from the cross member and remove the vehicle suspension assembly. In this case, it is necessary to note the number and location of the washers between the axis of the lower arm and the cross member, as well as the adjusting plates between the cross member and the body side member, so that when installing the units, put the washers and plates in their original place. Then remove the spring, gently unloading it, remove the fixture and repeat the operations on the other side of the suspension.

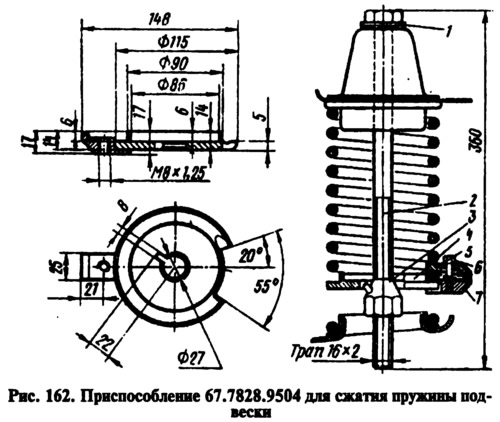

The main element of fixture 67.7828.9504 is the support plate 1. It is made in the form of a disk with a central hole with a diameter of 27 mm, on the side of which a socket for the nut lock is sawn. The disk has a support surface for the coil of the spring, according to the shape and dimensions of the spring support of the lower suspension arm. A handle with a threaded hole M8x1.25 is welded to the side of the disk, to which a clamping bar is screwed to fasten the plate on the coil of the spring.

Remove the mudguard and stabilizer bar. Supporting the engine with A.70526 traverse or hoist, remove the suspension with cross member assembly.

Install suspension components and parts in the reverse order of removal. At the same time, install only group A springs on the front suspension (marked with yellow paint).

To prevent incorrect distribution of forces in the rubber-metal joints, tighten the nuts and the axles of the levers in the following order:

- park the vehicle on a level surface and point the wheels straight ahead;

- load a car with a mass of 320 kg (4 people + 40 kg in the trunk).

Using a torque wrench, tighten the nuts securing the axles of the upper and then the lower arms and the nuts securing the axle of the lower arm to the cross member. Then check and adjust the wheel alignment.