Checking the generator on the stand

Allows you to determine the serviceability of the generator and the compliance of its characteristics with the nominal ones. The brushes of the generator under test must be well ground to the contact rings, and the rings themselves must be clean.

Install the generator on the stand and make the connections as shown in fig. 228. At the generator 37.3701 between the conclusions «30» and «61» the 12 V, 3 W lamp turns on. Turn on the electric motor of the stand, set the generator output voltage to 13 V with rheostat 4 and bring the rotor speed to 5000 min-1. Let the generator run in this mode for at least 2 minutes, and then measure the recoil current. For a working generator, it must be at least 45 A (55 A at the generator 37.3701).

If the measured value of the output current is less, then this indicates a malfunction in the stator or rotor windings, damage to the valves or wear of slip rings and brushes. In this case, a thorough inspection of the windings and valves is necessary to determine the location of the fault.

The voltage at the generator output is checked at a rotor speed of 5000 min-1. Set the recoil current to 15 A with a rheostat and measure the voltage at the generator output, which should be (14,1±0,5) At ambient temperature and generator (25±10) °C.

If the voltage is not within the specified limits, replace the voltage regulator with a new known-good voltage regulator and recheck. If the voltage is normal, then, therefore, the old voltage regulator is damaged. And if the voltage still does not fit within the above limits, then it is necessary to check the windings and generator valves.

Checking the excitation winding of the rotor

The excitation winding can be checked without removing the generator from the car, removing only the voltage regulator together with the brush holder. Having cleaned, if necessary, the contact rings with a sandpaper, an ohmmeter or a test lamp, check if there is an open in the excitation winding and if it closes to the housing.

Stator check

The stator is checked separately after disassembling the generator. Its winding leads must be disconnected from the rectifier valves. First of all, check with an ohmmeter or with the help of a test lamp and a battery, if there are any breaks in the stator winding and if its turns are closed to the housing.

The insulation of the winding wires must be free from overheating, which occurs during a short circuit in the rectifier valves. Replace a stator with such a damaged winding. Then check with a special flaw detector if there are short-circuited turns in the stator winding.

Checking the rectifier valves

The rectifier block contains three positive and three negative valves. The positive valves are pressed into the plate of the rectifier block connected to the output «30» generator. Negative valves have a minus of the rectified current on the case and are pressed into another plate of the rectifier unit connected to the case.

A good valve only allows current to flow in one direction, a bad valve may not allow current to flow at all (open circuit) or pass current in both directions (short circuit). If one of the rectifier valves is damaged, replace the entire rectifier unit.

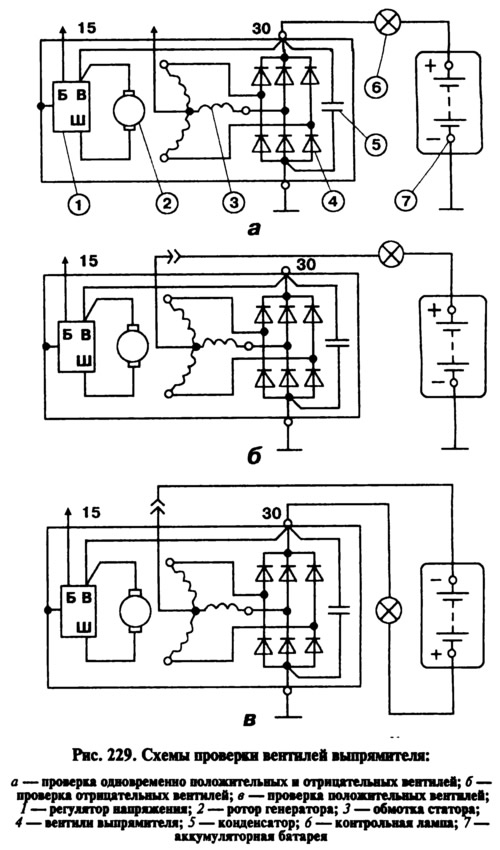

A short circuit of the valves can be checked without removing the generator from the car, after disconnecting the wires from the battery and the generator. You can check with an ohmmeter or with a lamp (1-3W) and battery as shown in Fig. 229.

First check for a short circuit in the positive and negative valves at the same time. For this «+» connect the batteries through the lamp to the clamp «30» generator, and «—» batteries - to the generator housing (pic. 229, a). If the lamp is on, both the negative and positive valves are shorted.

You can test for a short in the negative valves by connecting «+» batteries through a lamp with a plug of the neutral wire of the stator winding, and «—» batteries with alternator housing (pic. 229b). A lamp on indicates a short circuit in one or more of the negative valves. It should be remembered that in this case, the burning of the lamp may be due to the short circuit of the turns of the stator winding on the generator housing. However, such a malfunction is much less common than a short circuit of the valves.

To check for short circuits in positive valves «+» connect the batteries through the lamp to the clamp «30» generator, and «—» batteries - with a plug for outputting the zero point of the stator winding (pic. 229, in). A burning lamp will indicate a short circuit in one or more of the positive valves.

The 37.3701 generator does not have a separate plug for zero point output. But the rectifier unit fastening screws are connected to it. Therefore, when checking the valves of the generator 37.3701, attach the wires from the test lamp or battery to the heads of these screws. Also, disconnect the pin before testing «B» voltage regulator from terminal «30» generator and wire from the output «IN» voltage regulator.

An open in the valves without disassembling the generator can only be detected indirectly when checking the generator on the stand for a significant reduction (by 20-30%) the strength of the given current compared to the nominal. If the generator windings are in good order, and there is no short circuit in the valves, then the reason for the decrease in the output current is an open in the valves.

Checking additional generator diodes 37.3701

A short circuit of additional diodes can be checked without removing and disassembling the generator. As well as for checking the valves of the rectifier unit, it is necessary to disconnect the wires from the battery and the generator and the wire from the output «IN» voltage regulator.

«Plus» batteries through the lamp (1-3W, 12V) attach to output «61» generator, and «—» - to one of the screws securing the rectifier unit. If the lamp lights up, then there is a short circuit in one of the additional diodes. You can find a damaged diode only by removing the rectifier unit and checking each diode individually.

An open in additional diodes can be detected with an oscilloscope by distorting the voltage curve on the plug «61», as well as low voltage (below 14 V) on plug «61» at an average frequency of rotation of the generator rotor.

Checking the voltage regulator

The operation of the regulator is to continuously and automatically change the generator excitation current in such a way that the generator voltage is maintained within the specified limits when the rotor speed and generator load current change.

Vehicle check. To check, you must have a DC voltmeter with a scale of up to 15-30 V, an accuracy class of at least 1.0.

After 15 minutes of engine operation at medium speeds with the headlights on, measure the voltage between the terminal «30» and generator housing. The voltage should be in the range of 13.6-14.6 V.

In the event that a systematic undercharging or overcharging of the battery is observed and the regulated voltage does not fit within the above limits, replace the voltage regulator.

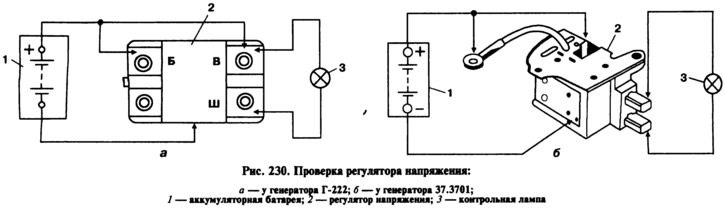

Checking the removed regulator. Check the voltage regulator removed from the generator according to the diagram shown in fig. 230. It is better to check the generator regulator 37.3701 assembled with the brush holder, since in this case you can immediately detect breaks in the brush leads and poor contact between the voltage regulator and brush holder leads.

Between pins «W» and «IN» regulator (or between the brushes on the alternator 37.3701) turn on the lamp with a power of 1-3 W, 12 V. To the conclusions «B» and «IN» and connect the power supply to the regulator body, first with a voltage of 12 V, and then 15-16 V. If the regulator is working, then in the first case the lamp should be on, and in the second it should not.

If the lamp is on in both cases, then there is a breakdown in the regulator, and if it does not light in both cases, then either there is an open in the regulator or there is no contact between the brushes and the outputs of the voltage regulator (on generator 37.3701).

Capacitor check

The capacitor serves to protect the electronic equipment of the car from voltage pulses in the ignition system, as well as to reduce radio interference. Capacitor damaged or loose on alternator (deterioration of contact with the body) detected by an increase in radio interference when the engine is running.

Approximately the health of the capacitor can be checked with a megger or tester (on a scale of 1-10 MΩ). If there is no break in the capacitor, then at the moment the probes of the device are connected to the terminals of the capacitor, the arrow should deviate in the direction of decreasing resistance, and then gradually return back. Capacitor capacitance 2.2uF±20%.