Open large image in new tab »

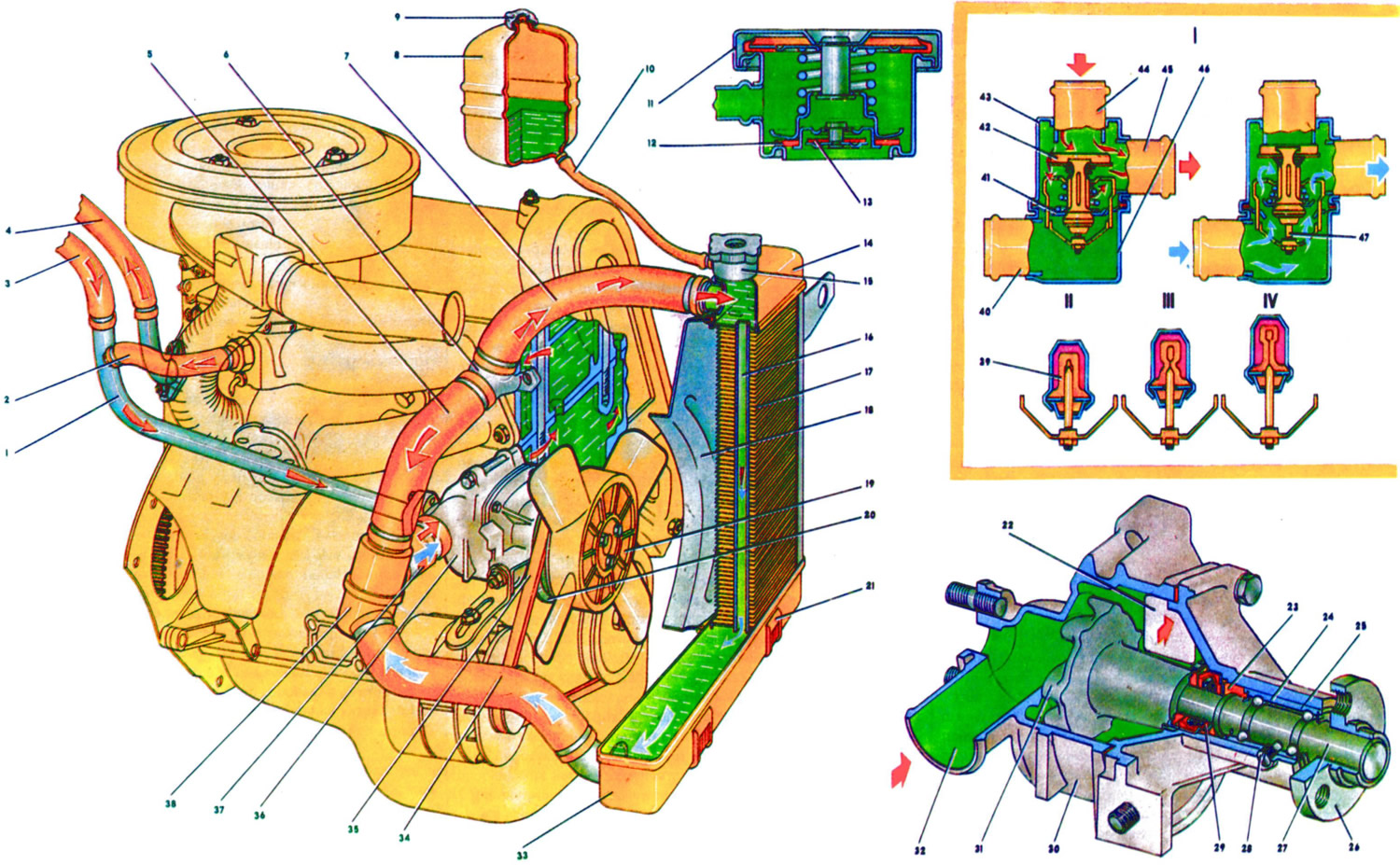

Pic. 7. 1. Pipe for draining fluid from the heater radiator to the coolant pump. 2. Coolant outlet hose from intake pipe. 3. Hose for draining coolant from the heater radiator. 4. Hose for supplying fluid to the heater radiator. 5. Thermostat bypass hose. 6. Cooling jacket outlet. 7. Radiator inlet hose. 8. Expansion tank. 9. Tank plug. 10. Hose from the radiator to the expansion tank. 11. Radiator cap. 12. Graduation (steam) tube valve. 13. Plug inlet valve. 14. The upper tank of the radiator. 15. Radiator filler neck. 16. Radiator tube. 17. Radiator cooling fins. 18. Fan cover. 19. Fan. 20. Coolant pump drive pulley. 21. Rubber support. 22. A window on the side of the cylinder block for supplying coolant. 23. Gland clip. 24. Coolant pump roller bearing. 25. Pump cover. 26. Fan pulley hub. 27. Pump roller. 28. Locking screw. 29. Gland seal. 30. Pump housing. 31. Pump impeller. 32. Pump inlet. 33. Lower radiator tank 34. Radiator outlet hose. 35. Radiator belt. 36. Coolant pump. 37. Coolant supply hose to the pump. 38. Thermostat. 39. Rubber insert. 40. inlet pipe (from the radiator). 41. Main valve. 42. Bypass valve. 43. Thermostat housing. 44. Branch pipe of the bypass hose. 45. Hose connection for supplying coolant to the pump. 46. Thermostat cover. 47. The piston of the working element. I - Scheme of thermostat operation. II - The temperature of the liquid is less than 80°C. III - Liquid temperature 80-94°C. IV - The temperature of the liquid is greater than 94°C.

The engine cooling system is liquid, closed type, with forced circulation of liquid. The system capacity is 9.85 liters, including the body interior heating system. The cooling system consists of the following elements: coolant pump 36, radiator, expansion tank 8, pipelines and hoses, fan 19, cooling jackets for the block and cylinder head.

When the engine is running, the liquid heated in the cooling jackets enters through the outlet pipe 6 through hoses 5 and 7 into the radiator or thermostat, depending on the position of the thermostat valves. Next, the coolant is sucked in by pump 36 and fed back into the cooling jackets.

The cooling system uses a special liquid TOSOL A-40 - an aqueous solution of antifreeze Tosol-A (concentrated ethylene glycol with anti-corrosion and anti-foam additives with a density of 1.12-1.14 g/cm3). TOSOL A-40 of blue color with a density of 1.078-1.085 g/cm3, has a freezing point of minus 40°C.

Checking the coolant level is carried out on a cold engine (at a temperature of plus 15-20°C) according to the liquid level in the expansion tank 8, which should be 3-4 mm above the mark "MIN".

The density of the liquid is checked with a hydrometer during vehicle maintenance. With an increase in the density of the liquid and a low level, distilled water is added. At normal density, the liquid of the brand that is in the cooling system is added.

With a low density of the coolant and the need to operate the car in the cold season, the liquid is replaced with a new one.

To control the temperature of the coolant, there is a sensor installed in the cylinder head and a pointer on the instrument panel. Under normal temperature conditions of engine operation, the pointer is at the beginning of the red field of the scale within 80-100°C. The transition of the arrow into the red zone indicates an increased thermal condition of the engine, which may be caused by malfunctions in the cooling system (loose pump drive belt, insufficient coolant or thermostat malfunction), and difficult road conditions.

The fluid is drained from the system through drain holes closed by plugs: one in the left corner of the lower tank 33 of the radiator, the other in the cylinder block on the left in the direction of the vehicle.

The car interior heater is connected to the cooling system. The heated fluid from the cylinder head enters through hose 4 through the heater radiator tap, and is sucked off by pump 36 through hose 3 and tube 1.

The coolant pump is centrifugal type, driven from the crankshaft pulley by the alternator drive V-belt.

The pump is attached to the cylinder block on the right side through the sealing gasket with bolts with a tightening torque of 22-27 Nm (2.2-2.7 kgf·m).

The housing 30 and the cover 25 of the pump are cast from an aluminum alloy. In the cover in the bearing 24, which is locked with a screw 28, a roller 27 is installed. The bearing 24 is double-row, non-separable, without an inner race. The bearing is filled with grease during assembly and is not subsequently lubricated.

The impeller 31 is pressed onto the roller 27 on one side, and the hub 26 of the pump drive pulley on the other. The end face of the impeller, in contact with the sealing ring, is hardened by high-frequency currents to a depth of 3 mm. The sealing ring is pressed against the impeller by a spring through a rubber cuff 29.

The stuffing box is non-separable, consists of an outer brass clip 23, a rubber cuff and a spring. The stuffing box is pressed into the cover 25 of the pump.

The pump housing has a suction pipe 32 and a window 22 towards the cylinder block for pumping coolant.

At normal tension of the pump drive V-belt, the belt deflection under a force of 100 N (10 kgf) should be within 10-15 mm.

Fan

The fan 19 is a four-blade impeller made of plastic, which is bolted to the hub 26 of the pump drive pulley. The fan blades have a variable installation angle along the radius and a variable pitch along the hub to reduce noise. For better performance, the fan is housed in shroud 18, which is bolted to the radiator brackets.

Radiator and expansion tank. The radiator with upper 14 and lower 33 tanks, with two rows of brass vertical tubes 16 and tinned cooling plates 17 is fastened with four bolts to the front of the body and rests on rubber supports 21.

The filler neck 15 of the radiator is closed with a plug 11 and connected by a hose 10 to a translucent plastic expansion tank 8. The radiator plug has an inlet valve 13 and an outlet valve 12, through which the radiator is connected by a hose to the expansion tank. Inlet valve is not pressed against the gasket (clearance 0.5-1.1 mm) and allows the inlet and outlet of coolant into the expansion tank as the engine warms up and cools down.

When a liquid boils or a sharp increase in temperature due to a small throughput, the inlet valve does not have time to release liquid into the expansion tank and closes, separating the cooling system from the expansion tank. With an increase in pressure when the liquid is heated to 50 kPa, the outlet valve 12 opens, and part of the coolant is discharged into the expansion tank.

The expansion tank is closed with a stopper, which has a rubber valve that operates at a pressure close to atmospheric.

Since 1988, radiators with aluminum cores made of two rows of horizontal round aluminum tubes and aluminum cooling plates have been installed on the engines of VAZ-2105, VAZ-2104 cars. Two-way radiator with plastic tanks and branch pipes for connecting hoses. One of the tanks has a partition. The radiator is collapsible, the core is attached to the tanks through sealing rubber gaskets. To increase the efficiency of liquid cooling, aluminum cooling plates are stamped with a notch, and plastic turbulators in the form of corkscrews are inserted into some of the tubes. All this ensures the turbulent movement of air and fluid in the tubes.

It must be remembered that it is not recommended to use water in the cooling system as a coolant with aluminum radiators in order to prevent corrosion of aluminum tubes.

Thermostat and operation of the cooling system The thermostat of the cooling system accelerates the engine warm-up and maintains the required thermal regime of the engine. Under optimal thermal conditions, the temperature of the coolant should be 85-95°C.

Thermostat 38 consists of a body 43 and a cover 46, which are rolled together with the seat of the main valve 41. The thermostat has an inlet pipe 40 for inlet of cooled liquid from the radiator, a pipe 44 of the bypass hose 5 for bypassing liquid from the cylinder head to the thermostat and a pipe 45 for coolant supply to the pump 36.

The main valve is installed in the thermoelement cup, in which the rubber insert 39 is rolled. The rubber insert contains a polished steel piston 47, fixed on a fixed holder. A heat-sensitive solid filler is placed between the walls and the rubber insert. The main valve 41 is pressed against the seat by a spring. Two racks are fixed on the valve, on which a bypass valve 42 is installed, which is pressed by a spring.

The thermostat, depending on the temperature of the coolant, automatically turns on or off the radiator of the cooling system and bypasses the liquid through the radiator or bypassing it.

On a cold engine, when the coolant temperature is below 80°C, the main valve is closed, the bypass valve is open. In this case, the liquid circulates through the hose 5 through the bypass valve 42 to the pump 36, bypassing the radiator (in a small circle). This ensures that the engine warms up quickly.

If the temperature of the liquid rises above 94°C., the temperature sensitive thermostat filler expands, compresses the rubber insert 39 and pushes out the piston 47, moving the main valve 41 to full opening. Bypass valve 42 closes completely. The liquid in this case circulates in a large circle: from the cooling jacket through hose 7 to the radiator and then through hose 34 through the main valve enters the pump, which is again sent to the cooling jacket.

Within the temperature range of 80-94°C, the thermostat valves are in intermediate positions, and the coolant circulates in small and large circles. The opening value of the main valve ensures gradual mixing of the liquid cooled in the radiator, which achieves the best thermal regime of the engine.

The temperature at which the main thermostat valve starts to open should be within 77-86°C, the valve travel should be at least 6 mm.

Checking the beginning of the opening of the main valve is performed in a tank of water. The initial water temperature should be 73-75°C. The temperature of the water is gradually increased by 1°C per minute. The temperature at which the stroke of the main valve is 0.1 mm is taken as the temperature at which the valve opens.

The simplest test of the thermostat can be carried out by touch directly on the car. With a working thermostat, after starting a cold engine, the lower radiator tank begins to heat up when the arrow of the liquid temperature gauge on the instrument panel is approximately 3-4 mm from the red zone of the scale, which corresponds to a coolant temperature of 80-95°C.