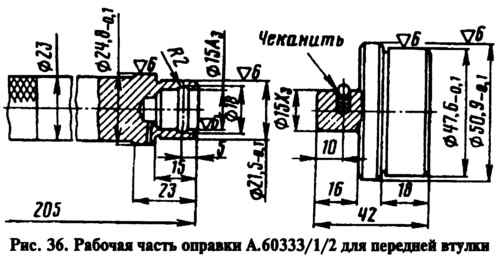

The auxiliary drive shaft must not have damage to the bearing journals, and the shaft gear must not have visually noticeable wear and chipping of the teeth. The roller should also be discarded if the bearing journals are worn: the front one up to a diameter of 48.01 mm, the rear one up to a diameter of 21.94 mm.

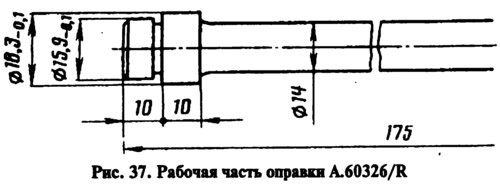

Loose fitting and ovality of the bushing of the oil pump drive gear and ignition distributor are not allowed. The inner surface of the bushing must be free of burrs. For pressing and pressing out, use a mandrel 1 (pic. 37) A.60326/R. After pressing the sleeve, expand to a diameter of 16.016-16.037 mm.