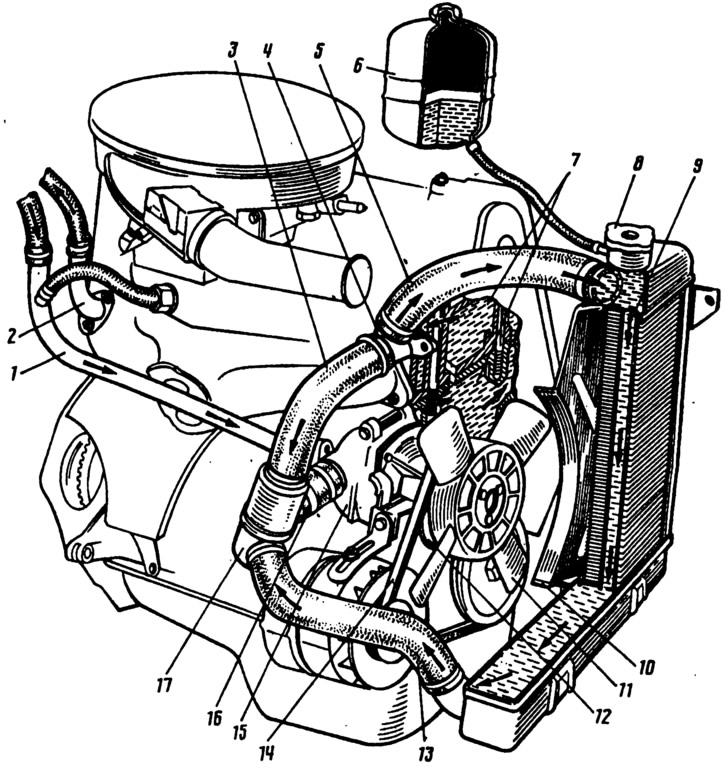

Pic. 27. Cooling system:

1 - pipe for draining liquid from the heater radiator and the intake manifold heating jacket; 2 - branch pipe for supplying liquid to the heater radiator; 3 - bypass hose; 4 - outlet pipe of the cooling jacket; 5 - radiator inlet hose; 6 - expansion tank; 7 - cooling jacket for the head and cylinder block; 8 - radiator cap; 9 - radiator tube; 10 - fan casing; 11 - fan; 12 - coolant pump drive pulley; 13 - radiator outlet hose; 14 - pump and generator drive belt; 15 - coolant pump; 1b - hose for supplying coolant to the pump; 17 - thermostat.

To control the temperature of the coolant, there is a sensor installed in the cylinder head and a pointer on the instrument panel.

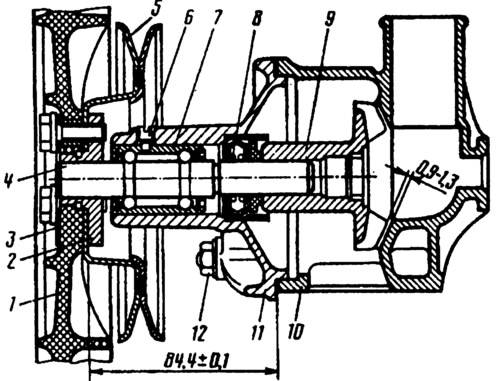

Coolant pump. Centrifugal pump (pic. 28) driven by a V-belt from the crankshaft pulley. On VAZ-2105, VAZ-2104 vehicles and their modifications, an engine coolant pump 2101 is installed.

Pic. 28. Coolant pump:

1 - fan; 2 - pulley hub; 3 - overlay; 4 - shaft 6 - bearing lock screw; 7 - bearing; 8 - stuffing box; 9 - impeller; 10 - body; 11 - cover; 12 - nut for fastening the pump cover.

Radiator. The radiator is mounted on two rubber supports (pillows) and is attached to the front of the body with four bolts. It consists of top and bottom forged brass tanks, two rows of brass tubes and tin plated cooling plates. The filler neck is closed with a stopper and connected by a hose to the expansion tank. A drain plug is screwed into the lower tank of the radiator.

The radiator cap has inlet and outlet valves through which the radiator is connected by a hose to the expansion tank. Inlet valve is not pressed against the gasket (gap 0.5-1.1 mm) and allows the release and inlet of coolant from the expansion tank during heating and cooling.

Since 1988, radiators with aluminum cores made of two rows of horizontal round aluminum tubes and aluminum cooling plates have been installed on the engines of VAZ-2105, VAZ-2104 cars. Two-way radiator with plastic tanks and branch pipes for connecting hoses. One of the tanks has a partition. The radiator is collapsible, the core is attached to the tanks through sealing rubber gaskets. To increase the efficiency of liquid cooling, aluminum cooling plates are stamped with a notch, and plastic turbulators in the form of corkscrews are inserted into some of the tubes. All this ensures the turbulent movement of air and fluid in the tubes.

It must be remembered that it is not recommended to use water in the cooling system as a coolant with aluminum radiators in order to prevent corrosion of aluminum tubes.