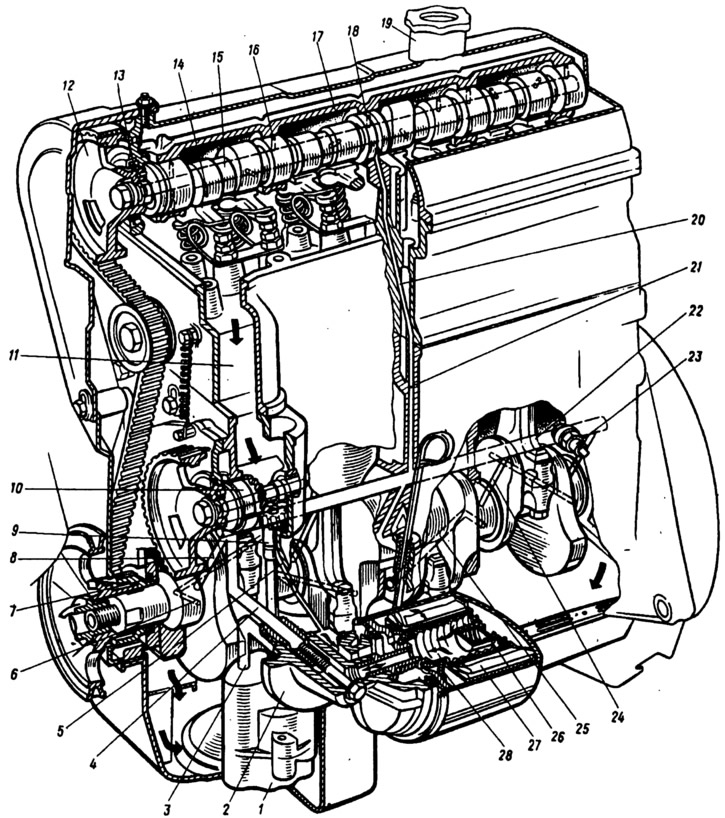

The lubrication system includes: oil pump 1 (pic. 33); inlet pipe with a filter mesh attached to the pump housing; full-flow oil filter mounted on the left side of the engine; filler neck with cap 19; oil level indicator in the crankcase; oil pressure sensor 23 connected to a control lamp.

Pic. 33. Lubrication system:

1 - oil pump; 2 - oil filter bracket; 3 - oil supply channel from the pump to the filter; 4 - horizontal channel in the cylinder block for supplying oil from the filter to the oil line: 3 - channel in the cylinder block for supplying oil to the oil pump drive gear and ignition distributor; 6 - channel in the neck of the crankshaft; 7 - front crankshaft oil seal; 8 - oil supply channel from the oil line to the main bearing and to the auxiliary drive shaft; 9 - bushing gear drive oil pump and ignition distributor; 10 - auxiliary drive roller; 11 - channel for draining oil into the crankcase; 12 - camshaft pulley; 13 - camshaft seal; 4 - channel in the camshaft cam; 15 - main channel in the camshaft; 16 - channel in the camshaft bearing journal; 17 - camshaft bearing housing; 18 - annular undercut on the middle support neck; 19 - oil filler cap; 20 - inclined channel in the cylinder head for supplying oil to the gas distribution mechanism; 21 - vertical channel in the cylinder block; 22 - main oil channel; 23 - oil pressure warning lamp sensor; 24 - oil supply channel to the main bearing; 25 - oil supply channel from the main bearing to the connecting rod; 26 - oil filter bypass valve; 27 - paper filter element of the oil filter; 28 - anti-drainage valve.

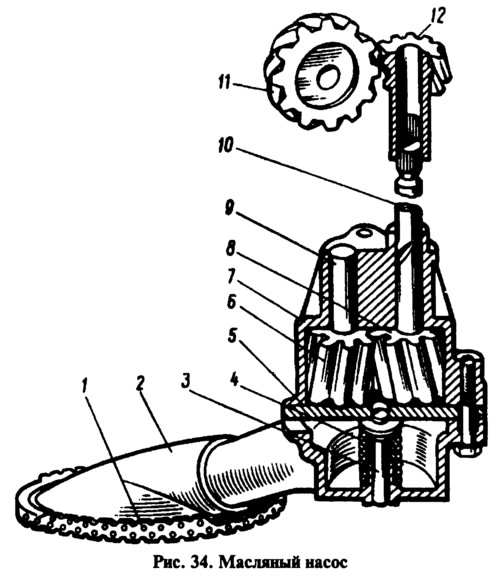

Oil pump

Oil pump (pic. 34) gear type is installed inside the crankcase and is attached to the cylinder block with two bolts. The drive gear 8 is fixedly fixed on the roller 10 and is supplied as a spare part complete with the roller. The driven gear 6 rotates freely on the axis P, pressed into the pump housing 7. An oil inlet pipe 2 with a filter mesh 1 and a built-in pressure reducing valve 3 is attached to the pump housing, which is pressed against the pump cover 5 by a spring. The valve actuation pressure is provided by a spring 4 of appropriate elasticity.

The oil pump is driven from the timing belt transmission to the auxiliary drive shaft, then through a pair of helical gears 11 and 12 to the shaft 10 of the oil pump. Gear 12 of the oil pump drive rotates in a ceramic-metal bushing pressed into the cylinder block. The splines of the oil pump and the ignition distributor are slotted into the slotted hole of the gear.

The oil pump and its drive are installed from the 2101 engine. The exception is for 2105 engines that have a timing belt transmission, in which 10 (see fig. 33) the belt pulley is installed.

Oil filter

The oil filter is full-flow, non-separable. Until 1986, an oil filter 2101 was installed on engines (shown in fig. 33), which, due to its larger dimensions than the 2105 filter, was installed using bracket 2. Later, the 2105 filter is installed on all the described engines. Due to the smaller filter size, it can be installed on all VAZ car engines.

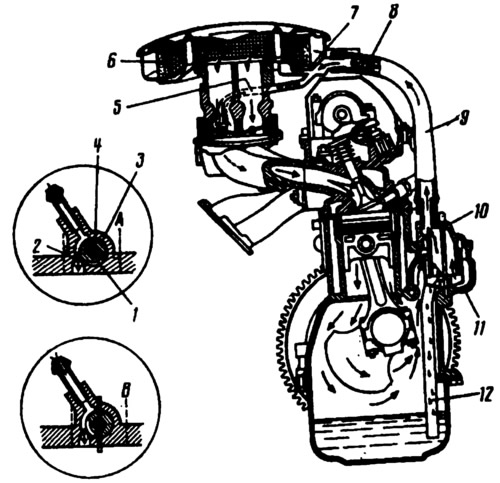

Crankcase ventilation

Provides forced removal of gases and gasoline vapors from the crankcase.

Crankcase gases are sucked off through hose 9 (pic. 35), put on the branch pipe of the cover 10 of the oil separator 11, into the suction manifold 7, located under the air filter. From there, gases can be sucked out in two ways: up into the space behind the filter element 6 of the air filter and further through the carburetor into the engine intake pipe and through the hose 5 into the carburetor spool device and further into the throttle space of the carburetor.

Pic. 35. Engine crankcase ventilation scheme:

A and B - the operation of the spool device of the carburetor at low (A) and at high (IN) frequency of rotation of the crankshaft;

1 - spool groove; 2 - calibrated hole; 3 - spool; 4 - axis of the throttle valve of the first chamber; 5 - a hose for venting gases into the throttle space of the carburetor; 6 - air filter element; 7 - suction manifold; 8 - flame arrester; 9 - gas suction hose; 10 - oil separator cover; 11 - oil separator; 12 - oil separator drain pipe.

The spool device regulates the gas suction mode at different engine crankshaft speeds. It consists of a spool 3, located on the axis 4 of the throttle valve of the first chamber, and a calibrated hole 2 in the carburetor throttle body.