Height gaps between piston rings and grooves check with a set of probes, setting the ring in the appropriate groove. In the lock of the rings, the gap is checked with a set of feelers, inserting the rings into a gauge having a hole diameter equal to the nominal diameter of the ring with a tolerance of±0.003 mm. For normal size rings, caliber 67.8125.9501 for engine 2105 or caliber A.96137 for engines 2101 and 2103 can be used.

The fit of the piston pin to the piston is checked by inserting a selected piston pin, previously lubricated with engine oil, into the bore of the piston boss. The landing is considered normal if the piston pin enters the hole with a simple thumb pressure and does not fall out of the boss when the piston is held vertically with the piston pin. If the finger falls out of the boss, then it is replaced with a finger of the next category. If there was a Category 3 pin in the piston, then replace the piston with the pin.

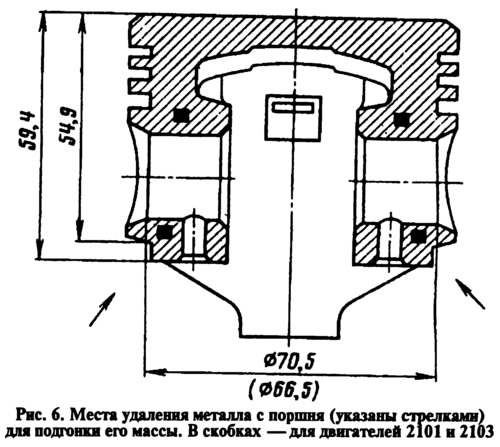

When replacing pistons, select them by weight, since the pistons of one engine should not differ by more than 2.5 g. If there is no set of pistons of the same group by weight, you can adjust it by removing metal with a file or cutter evenly from both sides on the lower outer side of the bosses under the piston pin (pic. 6). Metal removal, however, must not exceed 4.5 mm in relation to the nominal piston height (59.4 mm), and in width it is limited to a diameter of 70.5 mm for the 2105 engine or 66.5 mm for the 2101 and 2103 engines.

The pistons to the cylinders are selected so that the clearance between the piston and the cylinder is 0.06-0.08 mm for the 2105 engine (0.05 - 43.07 mm for engines 2101 and 2103). On a new engine, this is achieved by installing pistons of the same class as the cylinders. Used engines have some wear on pistons and cylinders. Therefore, it is necessary to re-select the pistons to the cylinders, measuring their diameter so that the gap is as close as possible to the calculated one.