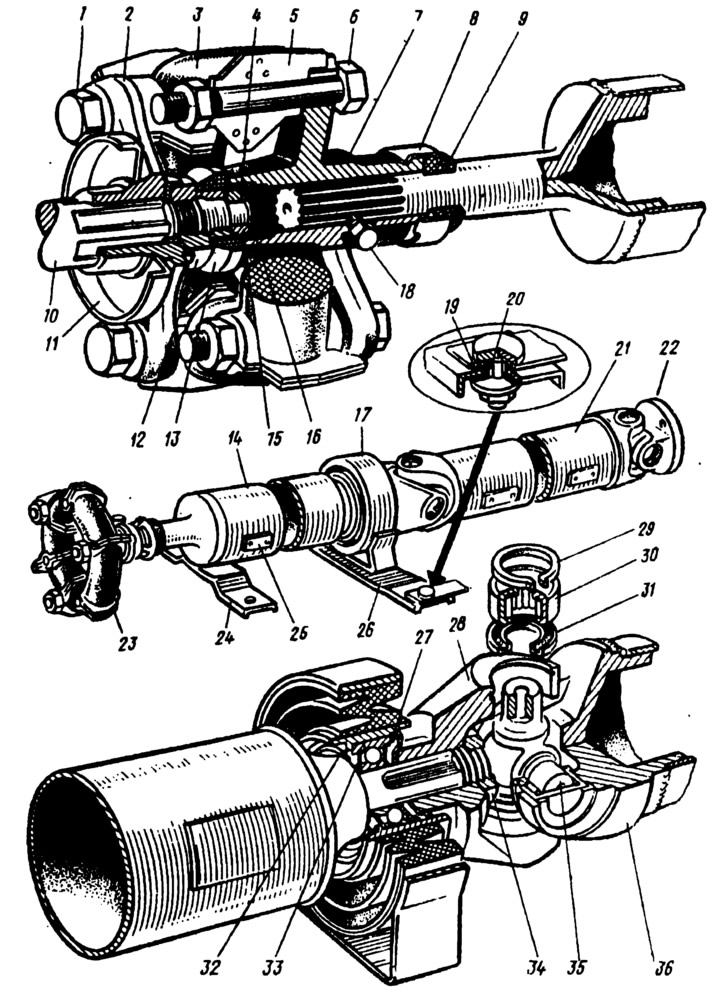

Pic. 126. Cardan gear:

1 - a bolt of fastening of an elastic coupling to a flange of a secondary shaft of a transmission; 2 - output shaft flange; 3 - rubber element of the elastic coupling; 4 - flange centering sleeve; 5 - insert of an elastic coupling; 6 - bolt for fastening the elastic coupling to the flange of the front propeller shaft; 7 - flange of the front propeller shaft; 8 - stuffing box holder; 9 - stuffing box; 10 - secondary shaft of the gearbox; 11 - dirt remover; 12 - flange fastening nut on the secondary shaft; 13 - centering ring seal; 14 - front propeller shaft; 15 - centering ring; 16, 27, 29 - retaining rings; 17 - intermediate support; 18 - cork; 19 - rubber bushing; 20 - remote bushing; 21 - rear driveshaft; 22 - flange fork of the universal joint; 23 - elastic coupling; 24 - safety bracket; 25 - balancing plate; 26 - cross member of the intermediate support; 28 - fork of the front propeller shaft; 30 - needle bearing; 31 - stuffing box; 32 - dust deflector; 33 - bearing; 34 - fork fastening nut; 35 - cross; 36 - universal joint fork.

Cardan shafts are made of thin-walled pipes, the ends of which are welded: the front cardan shaft has splined tips, and the rear one has universal joint forks. A flange 7 is located on the splines of the front tip of the front propeller shaft, which is connected to the flange 2 of the output shaft 10 of the gearbox through a rubber elastic coupling. The alignment of the connected shafts is ensured by the centering ring 15, pressed onto the end of the output shaft, and the centering sleeve 4, pressed into the flange 7. The ring 15 is fixed on the shaft by the retaining ring 16.

The spline connection is lubricated through a hole closed by a plug 18. The lubricant is held by a rubber gland 9, which is placed in a steel cage 8, and on the other side by a seal 13, put on a nut 12.

The rear splined tip of the shaft 14 rests on the ball bearing 33 of the intermediate support. On the splines of the tip, the yoke 28 of the intermediate cardan joint is fixed with a nut 34.

The intermediate support absorbs the vibrations of the driveline. It consists of a bracket fixed to the cross member with 26 bolts and nuts. The crossbar, in turn, is fastened with nuts on bolts welded to the body. Steel spacer bushings 20 and rubber insulating bushings 19 are installed on the bolts of the cross member, pressed by washers. The bracket contains a rubber cushion, which is vulcanized to the surface of the bracket and the bearing housing.

In the bearing housing there is a radial ball bearing 33 with seals. The bearing is fixed in the housing with a retaining ring 27. Dust deflectors 32 installed on both sides of the bearing protect the bearing from dirt. Lubricant Litol-24 is put into the bearing during assembly and is not replenished during operation.

The elastic coupling absorbs noise and vibrations of the driveline. It is made of six rubber elements 3, between which there are metal inserts 5 with holes for bolts 1 and 6. The inserts have six protrusions, three of which go into the grooves of the gearbox output shaft flange, and the rest into the grooves of the flexible coupling flange. This ensures that the flexible coupling is centered on the flanges.

The universal joint consists of two forks 28 and 36 fixed on the shafts and a cross 35, which connects the forks to each other. Needle bearing housings 30 are put on the hollow spikes of the cross. The bearing of the cross is sealed with an oil seal 31 located in a metal cage. Needle bearing assemblies are fixed in the holes of the forks with retaining rings 29, which are divided into five sizes according to the thickness. Each size corresponds to a specific color: 1.62 - yellow; 1.59 - black; 1.56 - blue; 1.53 - dark brown; 1.50 - unpainted. The selection of a retaining ring of one or another thickness provides an axial clearance of the crosspiece of 0.01-0.04 mm.