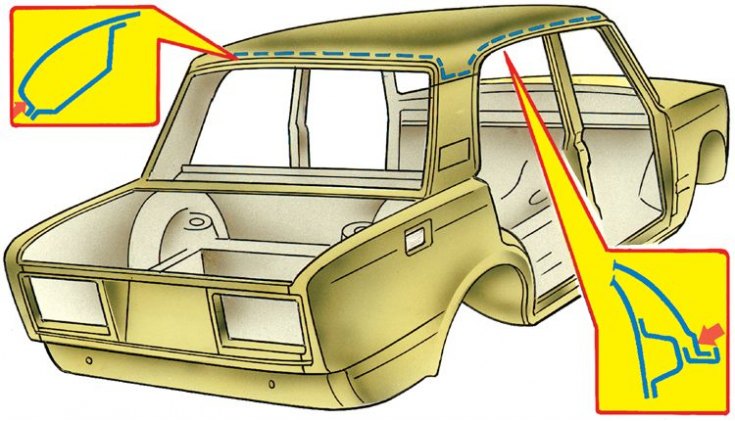

Roof replacement

The arrows show the cutting sites. The dotted line indicates the cutting lines of the roof panel

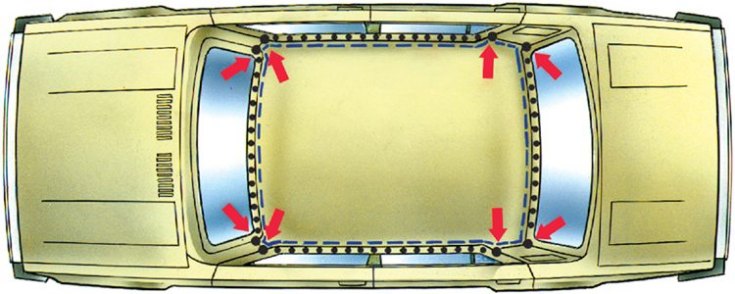

Roof welding points

The dots indicate the resistance welding seams. The arrows indicate the places of gas welding.

In most emergency cases with damage to the roof, it is required to replace it.

1. Remove the windshield, rear window, roof lining and accessories.

2. Lay the new panel on the roof of the bodywork and determine where to cut the side panels and A-pillars.

3. Backing away from the edge of the roof panel 8 mm, make a cut along the bends of the connections with the panels of the frame of the wind window, with the cross member of the frame of the rear window, gutters and roof side panels (see fig. Roof replacement).

4. At the side roof panels, cut the roof panel 10–15 mm above the markings.

5. Disconnect the roof panel, remove the remaining strips of the panel and clean the seats of the body and the new panel.

6. Align the body parts at the joints with the panel and adjust the new roof panel in place.

7. At the points indicated by the arrows, gas weld the roof panel to the windscreen panel and roof side panel (see fig. Roof welding points).

8. Check the fit of the panel and weld around the perimeter by resistance welding in 40–50 mm increments. Weld gas welding to the side panels of the roof.

9. In the absence of a contact welding machine, gas welding or electric welding in a carbon dioxide environment is allowed.