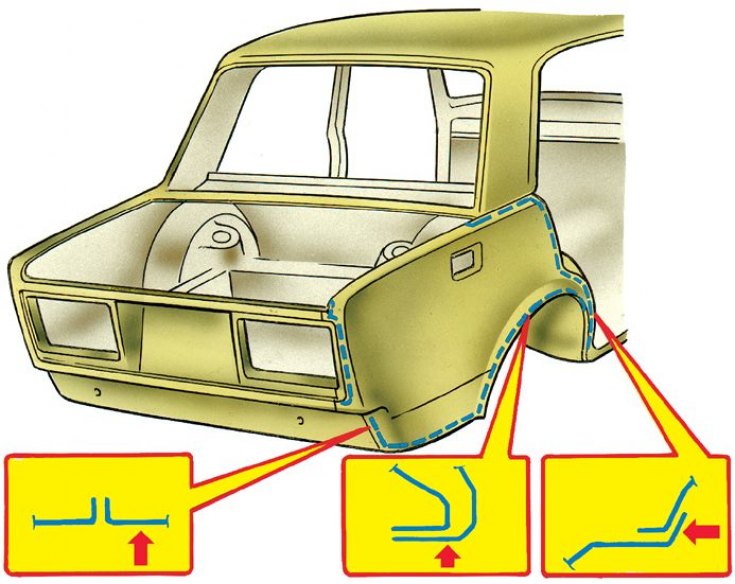

Rear fender replacement

The arrows on the fragments indicate the places where the wing was cut. The dotted line indicates cutting lines

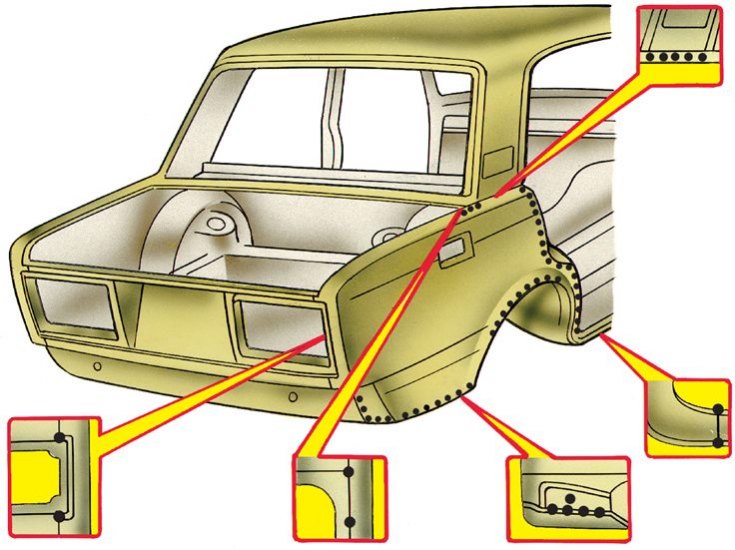

Rear fender welds

In the main view, the dots indicate the resistance welding seams. The fragments show the places of gas welding

1. When replacing the fender, remove the rear light and bumper. Empty the trunk, remove the rubber seal of the trunk lid and the fuel tank (if the right wing changes) and disconnect the wiring.

2. Cut with a thin sharpened chisel or cut with a grinder along the connection wing:

- with a rear wheel arch along the bend, stepping back from the edge of the wing 12–15 mm;

- with spare wheel floor (or fuel tank) along the bend, stepping back from the edge of the wing 12–15 mm;

- with a back panel, stepping back from the connection line 2 mm;

- with a rear window crossbar panel, stepping back from the bend edge of 2–3 mm;

- with the rear part of the sidewall along the bend, stepping back from the edge of the wing 15–20 mm (see fig. Rear fender replacement).

3. Cut down the elbow of the wing-to-rear panel connection, stepping back from the edge of the square 15 mm.

4. Using a 6-7 mm drill, drill out the resistance welding points at the connection of the wing to the roof side panel and disconnect the wing. Remove the remaining wing strips, straighten the deformed edges and clean up the seats of the body and the new wing.

5. Adjust the new wing at the landing site, grab it with grips and weld it with gas welding with L-62 or L-68 rods in the places indicated on the fragments (see fig. Rear fender welds).

6. Check the fit of the wing and weld it by resistance welding with a pitch of 40–50 mm.

7. In the absence of a contact welding machine, gas welding by flashing the edges with an intermittent seam 20 mm long every 30 mm with an L-68 bar is allowed. In the doorway, semi-automatic electric welding in a carbon dioxide environment is allowed.