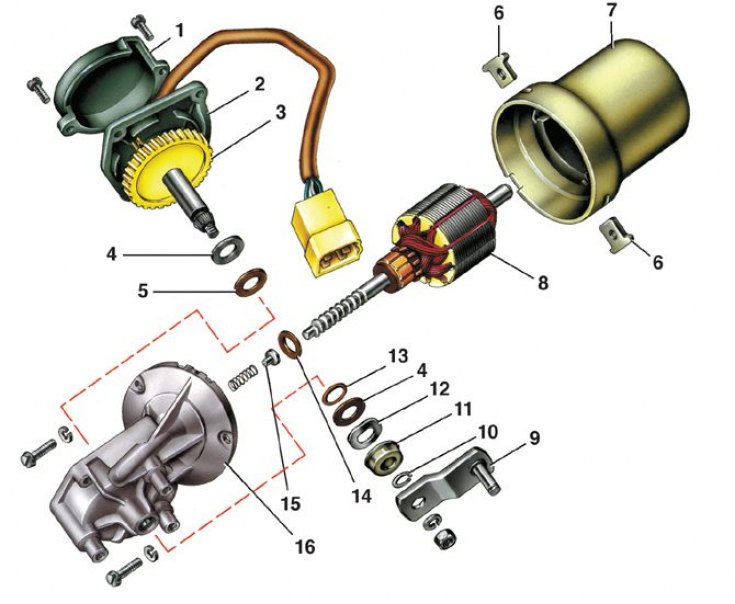

Windshield Wiper Motor Parts

1 - cover; 2 - panel; 3 – gear wheel of a reducer; 4 - steel washer; 5 - textolite washer; 6 – cover fastening plate; 7 - body; 8 - anchor; 9 - crank; 10 - retaining ring; 11 - protective cap; 12 - spring washer; 13 - sealing ring; 14 - adjusting washer; 15 - thrust bearing; 16 - motor cover

Gearmotor test data

| Maximum effective torque on the gearmotor shaft*, Nm (kgf·m) | 1,96 (0,2) |

| Current consumption* at 0.98 Nm (0.1 kgf·m), no more, A | 2,8 |

| Gearmotor shaft speed* at 0.98 Nm (0.1 kgf·m), min–1 | 50 |

* At 14 V and temperature (25±10) °C cold.

The electrical circuit for switching on the windshield wiper is shown in subsection 12.8.

Repair of the cleaner consists mainly in editing the deformed parts of the lever drive or replacing them with new ones. It is recommended to replace a defective gearmotor with a new one. Of the repair work on the gearmotor, only the replacement of the gear of the gearbox, the cleaning of the manifold and the adjustment of the limit switch are allowed.

Removal and installation

1. Remove the brushes with levers, open the hood and disconnect the wires from the battery and the cleaner gearmotor.

2. Loosen axle nuts (fittings) levers and remove equalizers and rubber gaskets.

3. Turn away nuts of fastening of an arm of a gearmotor and remove a cleaner in gathering.

4. If necessary, on a workbench, remove the gearmotor from the bracket and disassemble the lever drive.

5. Install the cleaner on the car in the reverse order of removal.

Dismantling, assembling and checking the technical condition of the cleaner gearmotor

1. To disassemble the motor reducer, unscrew the screws securing the cover 1 (see fig. Windshield Wiper Motor Parts) reducer and remove it together with the panel 2. Then unscrew the screws securing the cover 16 to the body 7 of the electric motor and separate them. Take out the anchor 8 of the electric motor.

2. To remove gear 3 of the reducer, unscrew the crank nut 9, remove the retaining ring from the axle and remove the axle with the gear and washers from the housing.

3. After disassembly, blow out the internal cavities of the electric motor with compressed air to remove deposits of coal dust and check the condition of the brushes and commutator.

4. The brushes must move freely, without jamming, in the brush holders, and the springs must be intact and have sufficient elasticity. Clean the collector with a fine-grained sandpaper, and then wipe it with a clean cloth lightly smeared with technical petroleum jelly. If the collector is badly burned or worn out, then it is better to replace the gearmotor with a new one.

5. Check for signs of seizing on the necks of the armature shaft. If necessary, clean them with fine-grained sandpaper.

6. When assembling, take the brushes away from the commutator so as not to break them or damage their edges, and insert the armature into the housing with extreme care, avoiding hitting the armature on the poles so as not to break them.

7. After assembly, to center the bearings, tap the gearmotor housing with a wooden mallet, and then check it on the stand.