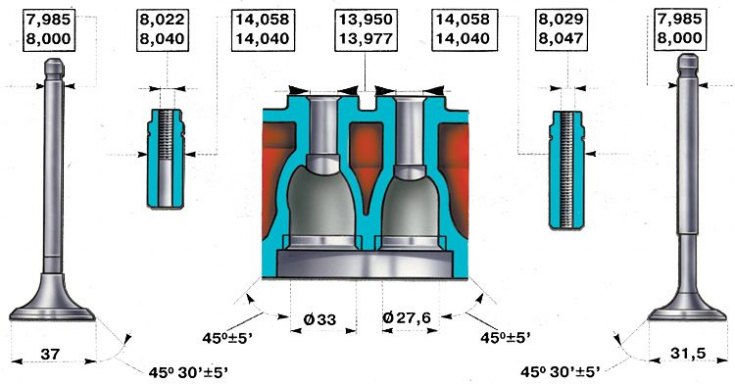

Main dimensions of valves and guide bushings

Cylinder head - common to four cylinders, cast aluminum alloy. The main dimensions of the valve cylinder head and guide bushings are given in the figure.

Cast iron seats and valve guides are pressed into the cylinder head. Seat chamfers are machined after pressing into the cylinder head assembly to ensure exact alignment of the chamfers with the holes in the valve guides.

The holes in the bushings are also machined after the bushings have been pressed into the cylinder head. This is done to ensure the accuracy of the bore diameter and location in relation to the seat and valve facets. The bores of the guide bushings have spiral grooves for lubrication. The inlet valve bushings are grooved up to half the length of the bore, while the exhaust valve bushings are grooved the entire length of the bore.

On top of the guide bushings, oil-slinger caps made of heat-oil-resistant rubber with a steel reinforcing ring are put on. The caps encircle the valve stems and serve to reduce the penetration of oil into the combustion chamber through the gaps between the valve guide and the valve stem.

Each valve has two cylindrical springs: external and internal, based on two support washers. At the top, the springs rest against a plate, which is held on the valve stem by two crackers, which, when folded, have the shape of a truncated cone.