1. Remove carbon deposits from valves. Check if the rod is deformed and if there are cracks on the plate; replace valve if damaged.

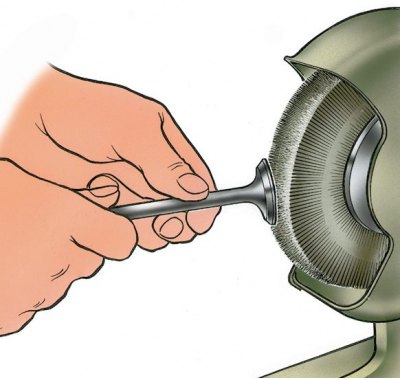

2. Check whether the working bevel is too worn or damaged. When grinding the working chamfer of the valve on a grinding machine, keep the chamfer angle equal to 45030'±5' and make sure that the thickness of the cylindrical part of the valve disc after grinding is not less than 0.5 mm, and also that the hard alloy layer is not removed from the exhaust valve, welded on the bevel.