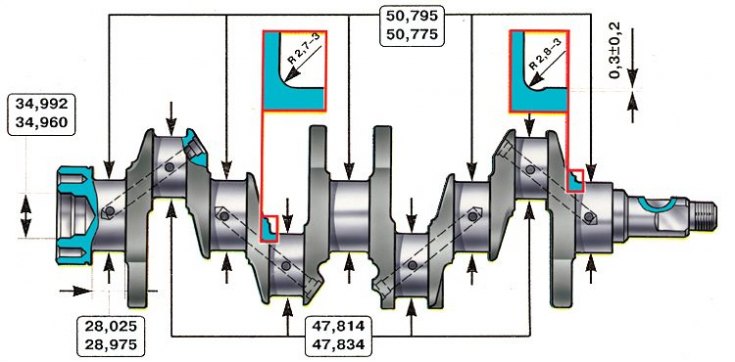

The main dimensions of the connecting rod and main journals of the crankshaft and their fillets

Crankshaft

The crankshaft is five-bearing, cast iron. The surfaces of the shaft journals are hardened by high-frequency currents to a depth of 2–3 mm. At the rear end of the crankshaft, there is a socket for the front bearing of the gearbox input shaft, along the outer diameter of which the flywheel is centered.

The main dimensions of the crankshaft are given in the figure.

The connecting rod and main journals of the crankshaft are connected by channels through which oil is supplied to lubricate the connecting rod bearings.

Technological outlets of the channels are closed with cap plugs, which are pressed in and for reliability are stamped in three points.

To prolong the service life of the crankshaft, it is possible to regrind the crankshaft journals when their surfaces are worn or damaged. By grinding, the diameters of the necks are reduced by 0.25; 0.5; 0.75 and 1.00 mm.

Inserts of main and connecting rod bearings

The upper shells of the 1st, 2nd, 4th and 5th main bearings have a groove on the inner surface, and the lower ones without a groove (until 1987, the lower shells of these bearings were installed with a groove). center liners (3rd) main bearings differ from the rest in their greater width and the absence of a groove on the inner surface. All connecting rod bearing shells are non-grooved, identical and interchangeable.

Flywheel

The flywheel is cast iron and equipped with a steel ring gear for starting the engine with a starter. The flywheel is mounted on the crankshaft so that the mark (cone-shaped hole near the gear rim) was against the connecting rod neck of the 4th cylinder.

The label is used to determine the TDC in the first and fourth cylinder.