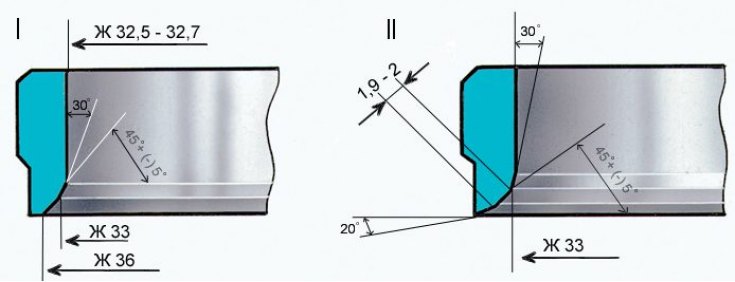

Intake valve seat profile

I - new seat; II - seat after repair

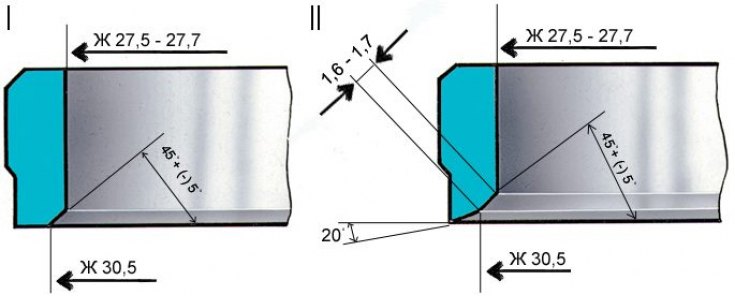

Exhaust valve seat profile

I - new seat; II - seat after repair

The shape of the chamfers of the valve seats is shown in the figures.

Examination

On the working chamfers of saddles (valve contact area) there should be no pitting, corrosion or damage. Minor damage can be repaired by sanding the seats. At the same time, remove as little metal as possible. You can grind both manually and with a grinder.

Grinding

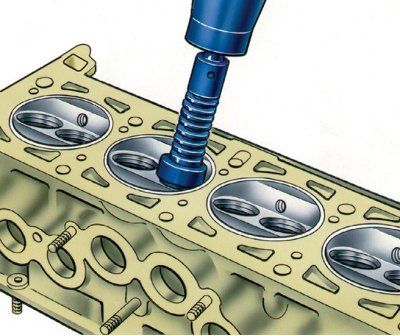

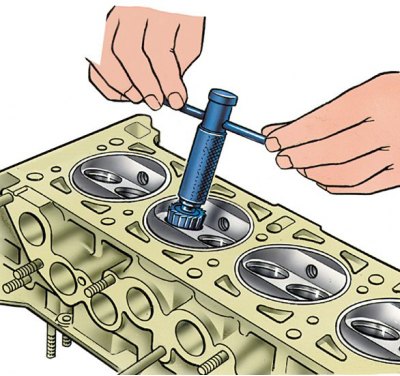

1. Install the head on the stand A.60353, insert the rod A.94059 into the valve guide bushing and clean the chamfers of the seats from carbon deposits with A.94031 and A.94092 countersinks for exhaust valve seats and A.94003 and A.94101 countersinks for inlet valve seats. Countersinks are put on the spindle A.94058 and centered by the guide rod A.94059.

Attention! Rods A.94059 are available in two different diameters: A.94059/1 for intake valve guides and A.94059/2 for exhaust valve guides.

2. Put the spring A.94069/5 on the guide rod A.94059, install the conical circle A.94078 for the exhaust valve seats or the circle A.94100 for the inlet valve seats on the spindle A.94069, fix the spindle in a grinder and grind the valve seat.

3. At the moment the wheel touches the seat, the machine must be turned off, otherwise vibration will occur and the chamfer will be incorrect. It is recommended to dress the wheel more often with a diamond.

4. For exhaust valve seats, bring the width of the working chamfer to the values specified in fig. Exhaust valve seat profile, countersink А.94031 (angle 200), and countersink A.94092, which eliminates hardening on the inner diameter. Countersinks are put on the A.94058 spindle and, as in grinding, are centered with the A.94059 rod.

5. At the inlet valve seats, bring the width of the working chamfer to the values specified in fig. The profile of the inlet valve seat, first processing the inner chamfer with a countersink A.94003 to obtain a size of ∅ 33, and then the chamfer 200 with a countersink A.94101 until a working chamfer with a width of 1.9–2 mm is obtained.