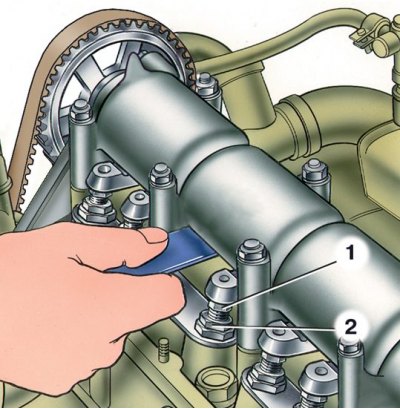

Checking the gap between the levers and camshaft cams with a feeler gauge A.95111

1 - adjusting bolt; 2 - adjusting bolt locknut

Adjust the gaps on a cold engine, after adjusting the belt tension. After adjustment, the gap should be 0.14–0.17 mm.

Valve clearance adjustment sequence

Angle of rotation of the crankshaft | N of the cylinder in which the compression stroke occurs (end) | N adjustable valves (cams) |

0 | 4 | 8 and 6 |

180° | 2 | 4 and 7 |

360° | 1 | 1 and 3 |

540° | 3 | 5 and 2 |

Adjustment

1. Turn the crankshaft clockwise until the mark on the camshaft pulley matches the mark on the bearing housing, which will correspond to the end of the compression stroke in the fourth cylinder. In this position, the clearance at the exhaust valve of the 4th cylinder is adjusted (8th cam) and inlet valve of the 3rd cylinder (6th cam).

2. Loosen the lever adjusting bolt locknut.

3. Insert between the lever and the camshaft cam a flat feeler gauge A.95111 with a thickness of 0.15 mm and a wrench, tighten or unscrew the adjusting bolt, followed by tightening the locknut, until the feelerstick enters with a slight pinch when the locknut is tightened.

4. After adjusting the gap at the exhaust valve of the 4th cylinder and the inlet valve of the 3rd cylinder, turn the crankshaft 180 degrees in succession and adjust the gaps, observing the sequence indicated in the table.