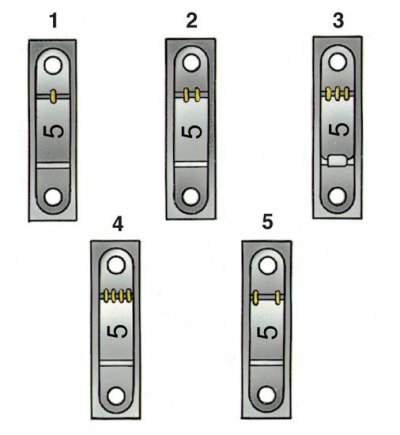

Labels on the main bearing caps and conditional number of the cylinder block

Supports are counted from the front of the engine.

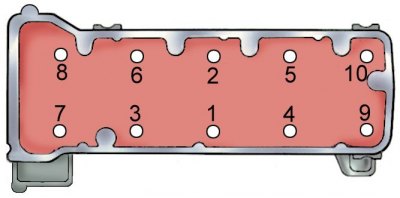

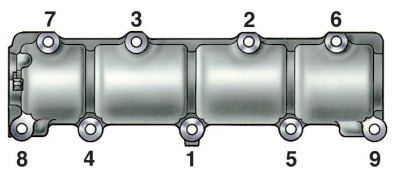

Cylinder Head Bolt Tightening Order

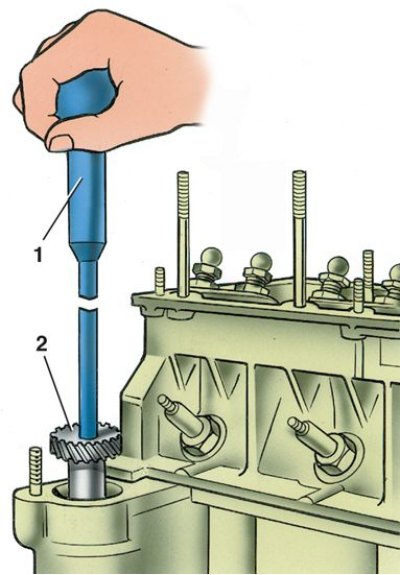

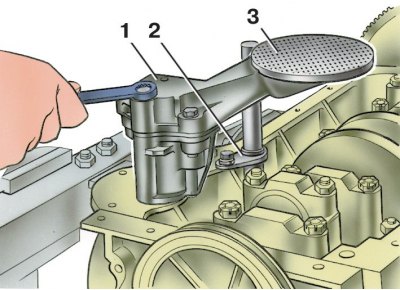

Installing the oil pump drive gear and ignition distributor

1 - mandrel 41.7820.4006; 2 - gear

1. Install the washed and cleaned cylinder block on the stand and wrap the missing studs.

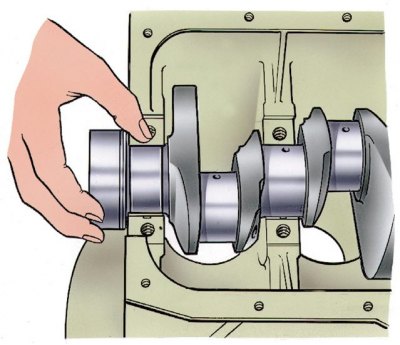

2. Place an insert without a groove on the inner surface in the middle bearing seat, and inserts with a groove in the remaining seats.

3. Inserts without a groove fit into the bearing caps.

Attention! Lubricate engine cylinders, as well as pistons and seals, bearing shells and thrust half rings of the crankshaft before installation with engine oil.

4. Lay the crankshaft in the main bearings and insert two thrust half rings, selected in thickness, into the sockets of the rear support.

5. Install the main bearing caps according to the marks (see fig. Labels on the main bearing caps and conditional number of the cylinder block).

Attention! Install the main bearing caps in the original block. For this, the cylinder block and the covers belonging to it are marked with the same reference number (see fig. Tags on the main bearing caps and the conditional number of the cylinder block and fig. Marking of the size group of cylinders on the block and conditional number of the cylinder block). Install the thrust half-rings with recesses to the thrust surfaces of the crankshaft, and place a steel-aluminum half-ring on the front side of the rear support, and a metal-ceramic half-ring on the back side (yellow color).

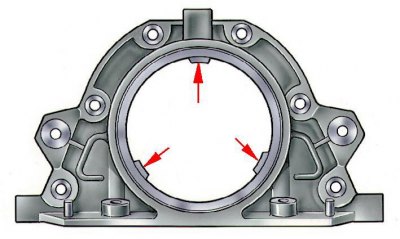

6. Put on the flange of the crankshaft the gasket of the gland holder, and insert the bolts of the front cover of the clutch housing into the sockets of the holder (the arrows indicate the protrusions for centering the holder relative to the crankshaft flange). Put the holder with the stuffing box on the mandrel 41.7853.4011 and, moving it from the mandrel to the crankshaft flange, attach it to the cylinder block.

7. Install the front cover 6 along the two centering bushes (see fig. Removing the flywheel) clutch housing.

8. Install the flywheel on the crankshaft so that the mark (cone-shaped hole) near the rim was against the axis of the connecting rod journal of the fourth cylinder, block the flywheel with the retainer A.60330 / R and bolt it to the crankshaft flange.

9. Match pistons to cylinders (see subsection 4.8.3) and assemble pistons with connecting rods (see subsection 4.8.8).

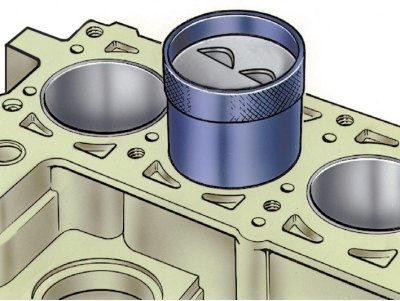

10. Using the bushing from the set 02.7854.9500, insert the pistons with connecting rods into the cylinders. The set consists of three bushings: one for regular size pistons and two for oversized pistons (increased by 0.4 and 0.8 mm). Therefore, it is necessary to select a bushing suitable for the size of the piston to be installed.

Attention! The finger hole on the piston is offset by 2 mm, so when installing the pistons in the cylinders, the mark "P" on the pistons must face the front of the engine.

11. Install the bearings in the connecting rods and connecting rod caps. Connect the connecting rods to the crankshaft journals, install the covers and tighten the connecting rod bolts.

12. Install the oil pump drive shaft and secure with the thrust flange.

13. Fit the two centering bushings on the block to the cylinder head with gasket, exhaust manifold and intake manifold. Tighten in sequence (see fig. Cylinder Head Bolt Tightening Order) fastening bolts in two steps:

- pre-torque 33.3–41.16 Nm (3.4–4.2 kgf·m);

- final torque 95.94–118.38 Nm (9.79–12.08 kgf·m).

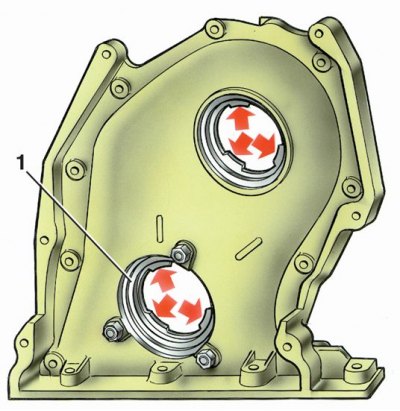

14. Attach the 1 oil seal holder with gasket to the camshaft drive cover (the arrows indicate the protrusions for centering the holder and cover relative to the crankshaft and the oil pump drive shaft), without finally tightening the fastening nuts.

15. Attach the camshaft drive cover with gasket to the cylinder block without completely tightening the nuts and bolts.

16. Use drift 67.7853.9548 to center the position of the cover relative to the roller 6 (see fig. Dismantling the front of the engine) oil pump drive and tighten the bolts and nuts securing the camshaft drive cover.

17. Using mandrel 67.7853.9549, center the position of the holder 1 of the front crankshaft oil seal and tighten the nuts of the holder.

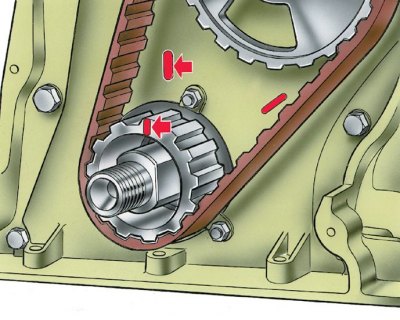

18. Install pulley 8 (see fig. Dismantling the front of the engine) on the roller 6 of the oil pump drive, without tightening the pulley mounting bolt. Install the toothed pulley 9 on the crankshaft.

Attention! The bolt for fastening the pulley of the oil pump drive shaft must be installed on the sealant according to TU 6-10-1048-73 or the TV-1215 sealant of the company "Three Bond".

19. Assemble the camshaft bearing housing (see subsection 4.11.8).

20. Clean the mating surfaces of the cylinder head and holder 6 (see fig. Removing the cylinder head) camshaft oil seal from the remnants of the old gasket, dirt and oil.

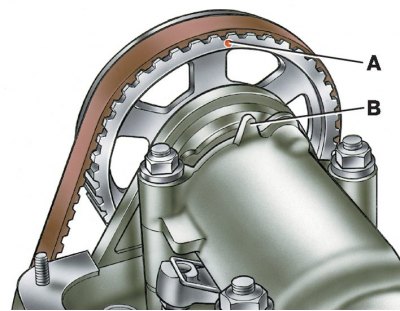

21. Apply to the surface of the cylinder head, mating with the gland holder, KLT-75TM sealant or a similar TV-1215 type sealant from the company "Three Bond". Rotate the camshaft so that the marks on the pulley and bearing housing line up (A - mark on the pulley, B - mark on the bearing housing).

22. Without knocking down the position of the shaft, secure the assembled bearing housing to the cylinder head by tightening the nuts in a certain sequence.

Attention! It is allowed to start the engine 1 hour after applying the liquid gasket.

23. Attach the bracket with the tension roller to the cylinder block without finally tightening the mounting bolts. Rotate the bracket to the extreme left position.

24. Turn the crankshaft so that the mark on the toothed pulley matches the mark on the camshaft drive cover.

25. Put the belt on the pulleys and on the tension roller, push the tension roller bracket to the right and install the tension spring.

26. Gently rotate the crankshaft two turns while keeping the belt under constant tension, and when the crankshaft stops, hold it to prevent the belt from loosening. Thus, the spring will set the required belt tension. Tighten the idler pulley bracket bolts.

27. Check if the labels match. If the marks do not match, then reinstall the belt.

28. Adjust the clearance between the camshaft cams and the valve actuating levers.

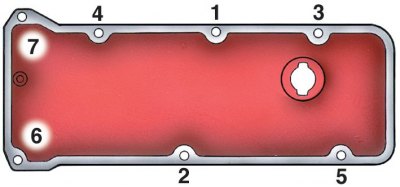

29. Install the cylinder head cover with gasket and tighten the fastening nuts in the sequence shown in the figure. Install the camshaft belt drive guards.

30. Install the alternator drive pulley and secure it with a ratchet.

31. Lubricate the oil filter O-ring with oil and install it by hand-tightening it to the fitting on the adapter. Install the crankcase breather oil separator, breather cap and attach the oil separator drain tube retainer.

32. Install the oil pump (1 - oil pump, 2 - drain tube retainer, 3 - oil separator drain tube) and oil sump with gasket.

33. Install the coolant pump, alternator bracket and alternator. Put the belt on the pulleys and adjust its tension.

34. Install the heater core inlet pipe and outlet pipe on the cylinder head. Attach the heater core outlet pipe to the coolant pump and exhaust manifold.

35. Install control gauges.

36. Install the oil pump drive gear and ignition distributor (see fig. Installing the oil pump drive gear and ignition distributor). Install the ignition distributor. Wrap the spark plugs, install the key 67.7812.9515 on them and tighten with a torque wrench.

37. Install the fuel pump as directed (see subsection 4.14.2).

38. Install the carburetor, attach hoses to it and close it with a technological plug.

39. Pour oil into the filler neck on the cylinder head cover.