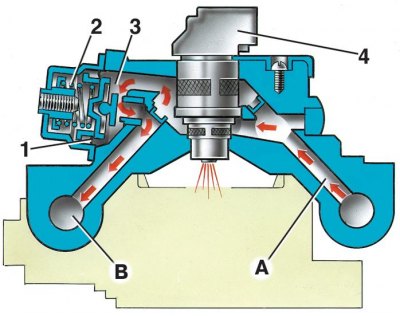

Scheme of the fuel pressure regulator

1 - pressure regulator diaphragm; 2 - spring; 3 - pressure regulator valve; 4 - nozzle; A - fuel supply channel; B - fuel drain channel

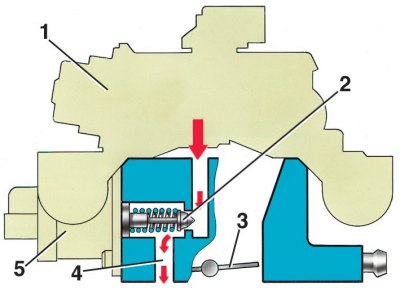

Scheme of the idle speed controller

1 - fuel supply housing; 2 – the valve of a regulator of idling; 3 - throttle valve; 4 - idle channel; 5 - idle speed regulator

Central fuel injection unit (see fig. Central injection unit) mounted on the intake pipe instead of the carburetor and consists of a fuel supply housing (top of the unit) and throttle body (lower part of the unit). In the fuel supply housing there is a nozzle 2 for fuel injection and a fuel pressure regulator 1. In the throttle body there is an idle speed controller 9, a throttle valve and a throttle position sensor 4. There are three nozzles 6, 7 and 8 connected to the throttle space for vacuum extraction.

The fuel pressure regulator maintains the pressure of the fuel supplied to the injector at a constant level within 190–210 kPa. It consists of 3 valve (see fig. Scheme of the fuel pressure regulator) with diaphragm 1, pressed by a calibrated spring to the seat in the fuel supply housing of the unit.

When the fuel pressure becomes higher than normal, it overcomes the spring force, the valve opens, excess fuel through the channel "IN" and the drain line drains into the fuel tank and the fuel pressure is reduced. When the pressure drops below normal, the valve is pressed against the seat by a spring and the fuel drain stops.

Idle speed regulator 5 (see fig. Scheme of the idle speed controller) regulates the speed of the crankshaft in idle mode, controlling the amount of air supplied to bypass the closed throttle through channel 4. It consists of a two-pole stepper motor and a cone valve connected to it 2. The valve is extended or retracted by a stepper motor, according to signals from the ECU.

When the regulator needle is fully extended (which corresponds to about steps), the valve completely blocks the air passage. When the needle is pushed in, an air flow is provided that is proportional to the number of steps the needle moves away from the seat.

Nozzle 4 (see fig. Scheme of the fuel pressure regulator) is a solenoid valve. When a voltage pulse arrives at it from the ECU, the valve opens and fuel is injected through the sprayer with a finely sprayed jet under pressure into the mixing chamber above the throttle valve. After the electrical impulse is stopped, the spring-loaded valve shuts off the fuel supply.

The electric fuel pump is a two-stage, rotary type, non-separable, installed in the fuel tank. It provides fuel supply under pressure more than 284 kPa. The electric fuel pump is switched on using the auxiliary relay 21 (see subsection 12.2)

The electric fuel pump is located directly in the fuel tank, which reduces the possibility of vapor locks, because. fuel is supplied under pressure, not under vacuum.

The fuel filter is built into the supply line between the electric fuel pump and the central fuel injection unit, and is installed in the engine compartment on the left mudguard. The filter is non-separable, has a steel housing with a paper filter element.

The intake pipe electric heater is located at the bottom of the intake pipe, directly below the central injection unit. It serves to accelerate the heating of the intake system of a cold engine. This ensures rapid evaporation of the fuel and its uniform distribution over the cylinders. The result is improved cold driving performance and reduced exhaust emissions.

The ECU turns on the electric heater using the auxiliary relay 22 (see subsection 12.2) all of the following conditions are met: coolant temperature is below 65°C, intake air temperature is below 80°C, and supply voltage is greater than 8V. These conditions occur with the engine running cold with minimal electrical load from the accessories.

The ECU turns off the electric heater when one of the following conditions is met: the coolant temperature is greater than or equal to 65°C, the intake air temperature is greater than 80°C, and the supply voltage is less than 6 V. These conditions occur with a warm engine and / or with a high electrical load from auxiliary units.