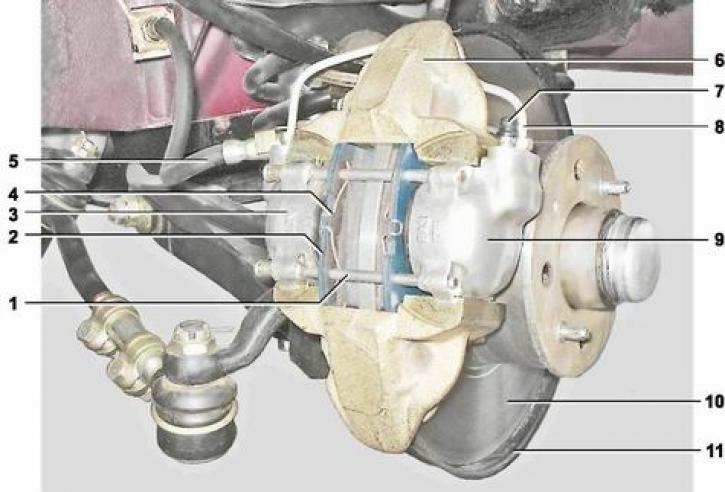

Front wheel brake: 1 - guide pin of the pads (2101-3501132); 2 - brake shoe (2101-3501089); 3 - internal working cylinder (2101-3501182/83); 4 - clamping spring pads (2101-3501035); 5 - front wheel brake hose (21061-3506060); 6 - support (2101-3501016/17); 7 - fitting for bleeding the brake mechanism of the front wheel (2101-1602591); 8 - connecting tube of working cylinders (2101-3501086-01/85-01); 9 - outer working cylinder (2101-3501180/81); 10 - brake disc (2101-3501070); 11 - protective cover (2101-3501146/47)

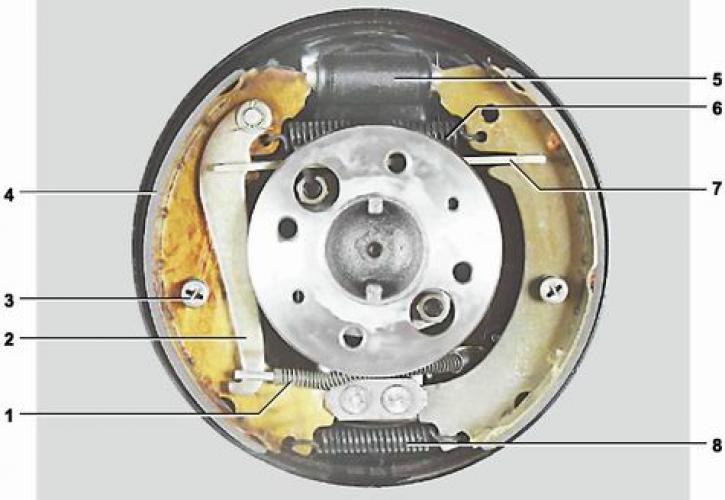

Rear wheel brake: 1 - rear parking brake cable (2101-3508180); 2 - spacer lever parking brake (2101-3507034/35); 3 - cup outer support post (2101-3502104); 4 - brake shoe (2101-3502090-01); 5 - working cylinder (2105-3502040); 6 - upper coupling spring (2101-3502035); 7 - spacer bar (2101-3507036); 8 - lower coupling spring (2101-3502038)

The car has two brake systems - working and parking. Hydraulic drive The working system consists of two independent circuits that actuate the brake mechanisms of the front and rear wheels. In the event of a malfunction in the operation of one circuit, the car is braked by the second circuit, albeit with an increase in the stroke of the brake pedal and braking distance. Working system consists of a pedal assembly, a vacuum booster, a master brake cylinder, a reservoir with a brake fluid level sensor, pipelines, front and rear wheel brakes with working cylinders and a rear brake pressure regulator.

The brake pedal is fixed on the same axis as the clutch pedal and is equipped with a return spring. Above the pedal is a brake light switch, the buffer of which, when properly adjusted, should touch the pedal stop. When the brake pedal is depressed, the switch contacts close and the brake signal lamps in the rear lights come on.

vacuum booster, mounted on the bulkhead of the engine compartment, serves to reduce the force on the brake pedal due to vacuum in the intake piping when the engine is running.

Master brake cylinder mounted on two studs screwed into the body of the vacuum booster, and attached to it with nuts. The fittings of the brake pipes of the front and rear circuits of the working brake system are screwed into the cylinder.

A tank is fixed on the partition of the engine compartment with a clamp, from which brake fluid is supplied through hoses to the main brake cylinder. The reservoir is marked with maximum and minimum fluid levels. A liquid level sensor with a float is installed in the tank lid. When the liquid level in the tank falls below the permissible level, a signal lamp lights up in the instrument cluster with a red light.

Front wheel brake - disc and consists of a cast iron, non-ventilated brake disc, a caliper with two working cylinders and two brake shoes. The brake disc is replaced when its working surface is worn down to a thickness of less than 9.5 mm. The working cylinders of the right and left brake mechanisms are not interchangeable. The minimum allowable thickness of the lining of the brake pad of the front wheel is 1.5 mm.

Rear wheel brake - drum and consists of a brake drum, a working cylinder, two brake shoes with coupling springs and a spacer lever for the parking brake drive. Brake drum - aluminum with cast iron insert. The largest permissible inner diameter of the drum during wear or after boring is 251 mm.

The working cylinder is two-piston, with a mechanism for automatically adjusting the gap between the drum and the shoes. The main element of the mechanism for automatic clearance adjustment are two elastic steel split rings mounted on pistons in the working cylinder with an axial clearance of 1.25-1.65 mm. The thrust rings are installed in the cylinder with an interference fit, providing a shear force along the cylinder mirror of at least 35 kgf, which exceeds the force from the brake shoe coupling springs. As the brake pads wear, the pistons move the rings in the cylinder during braking, thereby maintaining a constant gap between the drum and the pads.

To reduce the braking force on the rear axle, a pressure regulator is included in the hydraulic drive of the brake mechanisms of the rear wheels. It prevents the car from skidding during braking by limiting the pressure in the working cylinders, depending on the position of the rear of the body relative to the rear axle beam.

Parking brake drive - mechanical, cable, on the brake mechanisms of the rear wheels. It consists of a parking brake lever, a front cable, a guide, a rear cable and a parking brake expansion lever. When the parking brake lever is moved to the upper position, the spacer levers mounted on the shoes rotate and act on the spacer bars. The brake shoes of the rear wheels move apart and fix the drums from rotation.

During operation, the parking brake system requires periodic adjustment. This is due to the wear of the pad linings and the pulling of the drive cables.