It is more convenient to perform work related to checking or repairing suspension elements on a viewing hole or overpass with an assistant.

We evaluate the condition of rubber-metal hinges, protective covers of ball bearings, anti-roll bar cushions, the presence of deformations of the levers and their axes. Ball bearings with torn protective covers are recommended to be replaced as an assembly (see "Ball joints - replacement"). Torn, cracked or broken stabilizer pads - replace (see "Pillows and a bar of the stabilizer of cross stability - replacement"). We check the condition of the shock absorbers and springs, as well as the tightening of the threaded connections of the suspension parts.

Checking the rubber-metal hinges of the suspension arms

In case of one-sided wear or rupture, rubber-metal joints must be replaced. Wear of the hinges is one of the reasons why it is impossible to adjust the camber angle when all the washers are removed from under the lower arm axle.

1. We prepare the car for operations (see "Vehicle preparation for maintenance and repair").

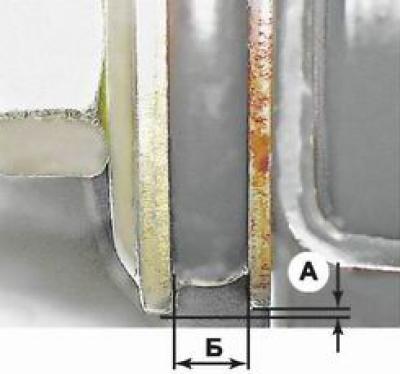

2. Measure the radial displacement A thrust washer of the hinge relative to the end face of the outer sleeve and the distance B between the inner ends of the thrust washer and the outer sleeve.

Size A must not exceed 2.5 mm for both levers, and the size B - 3-7.5 mm (for the bottom) and 1.5-5 mm (for upper arm). If size B does not correspond to the above tolerance, then it is necessary to check the correctness of pressing the rubber-metal hinge into the lever.

Checking the condition of the upper ball joint

An assistant is required to complete the work.

1. Have an assistant depress the brake pedal and hold it during the check in order to eliminate the possible influence of the clearance in the hub bearings.

2. With sharp movements, shake the wheel by the upper part in a plane perpendicular to the longitudinal axis of the car.

You can check the condition of the ball joint in another way.

1. Using a mounting blade, swing the upper arm alternately up and down and check for play between the pin and the ball joint body.

2. If play is found, the upper ball joint must be replaced (see "Ball joints - replacement").

Checking the condition of the lower ball joint

1. We clean the lower part of the ball joint from dirt and with a key by 7 mm open the cork.

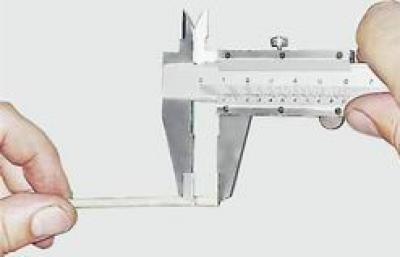

2. If the check is carried out on a viewing hole or overpass, then we measure the distance from the lower end of the support to the spherical surface of the ball pin with a caliper depth gauge.

3. If the condition of the lower ball joint is checked on a flat horizontal platform and it is impossible to use a caliper due to its length, then, having unscrewed the plug, insert a piece of wire into the ball joint and put a mark on it flush with the end face of the ball joint.

4. With a caliper we measure the distance from the upper end of the wire to the risks.

5. If this distance is more than 11.8 mm, we replace the ball joint.

6. To lubricate the hinge, we screw an oiler into the ball joint and apply lubricant to the support cavity with a supercharger, making sure that the protective cover of the support does not swell.

7. We check the presence of axial play in the bearings of the front wheel hub. Having hung the wheel and holding it in a vertical plane, alternately with sharp movements of the upper part of the wheel towards ourselves, and the lower part away from ourselves, we determine the presence of backlash.

With a noticeable backlash, we adjust the clearance in the bearings (see "Front wheel bearings - adjustment").

Checking the condition of shock absorbers and springs

1. Alternately, vigorously apply force from top to bottom to the front fenders of the car. The body should return to its original position with only one upward movement. Otherwise, both shock absorbers must be replaced. In the presence of fluid leaks, wear or cracking of rubber-metal joints, deformation of the rod - shock absorbers must be replaced, both at the same time.

2. We examine the suspension springs. Sagging, deformed or cracked springs must also be replaced on both sides at the same time.