We replace the hub bearings in pairs with increased noise that cannot be eliminated by adjustment.

It is not difficult to determine which side the bearing is worn on. To do this, you need to listen to the increase in noise from the worn bearing when the car is cornering. If the noise increases when passing a right turn, the left wheel hub bearing is faulty, and vice versa.

Disassembly

1. We prepare the car for operations (see "Vehicle preparation for maintenance and repair").

2. Remove the brake caliper (see "Front wheel brake mechanism - disassembly"). In order for the caliper not to hang on the brake hose, we tie it to the upper suspension arm with wire or rope.

3. socket wrench by 27 mm unscrew the hub nut (see "Front wheel bearings - adjustment").

Remove the washer and separator of the outer bearing with rollers and the inner ring.

4. Pulling towards you, remove the hub with the brake disc from the steering knuckle pin.

5. Using sliding pliers or a screwdriver, we remove the oil seal from the hub.

6. We remove the cage of the inner bearing with rollers without the outer ring from the hub.

7. We clean the cavity of the hub from the old grease and wipe the inner surface of the hub with a rag moistened with kerosene or white spirit.

8. To replace the bearings, pry off the split spacer sleeve with a slotted screwdriver and remove it.

9. Deep socket socket wrench by 7 mm (12 mm - on cars of early releases) unscrew the two guide pins.

10. Remove the distance ring and brake disc from the hub.

11. We fix the hub in a vice. We apply light blows with a hammer in a circle through a drift on the outer ring of the inner bearing.

12. Press out the ring.

13. Turning the hub in a vice, similarly press out the outer bearing ring.

Assembly

1. We wash all parts in kerosene or white spirit, apply grease to the seats of the hub bearings.

2. It is convenient to press the outer rings of the bearings in a vice, through wooden spacers, using rings from old bearings as mandrels, which we orient with a smaller cone diameter inside the hub. We press the new rings into the hub until they stop.

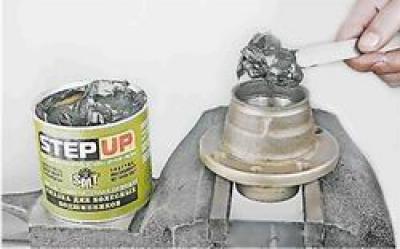

3. We apply grease Litol-24 or its analogues to the separator and the ring of the inner bearing. We put about 40 g of grease in the space between the bearings.

4. We install the inner bearing separator with rollers and the inner ring into the hub, having previously applied grease to it.

5. Install the spacer.

6. With a hammer and a suitable tool (e.g. mounting blade or outer ring of the old bearing) press a new seal into the hub.

7. We fix the brake disc with a spacer ring on the hub with two pins and install the hub on the pivot of the steering knuckle.

8. Apply grease to the outer bearing separator, put the inner ring on the trunnion, install the washer and screw on the new hub nut.

9. Adjust the clearance in the hub bearings (see "Front wheel bearings - adjustment").