Angle of longitudinal inclination of the axis of rotation (caster) - this is the angle between the vertical and the axis of rotation of the wheel when viewed from the side. The angle is regulated by changing the number of shims on the bolts of the lower arm axle, suspension, which ensures the stabilization of the wheels when the vehicle is moving in a straight line.

Camber angle - this is the angle between the plane of rotation of the wheel and the vertical line passing through the center of the contact patch of the tire with the road surface. The angle is adjusted by simultaneously changing the number of shims of the same thickness on both bolts of the lower arm axle, which ensures the correct position of the wheel during suspension operation wheel alignment - the difference in the distances between the front and rear points of the inner part of the rims of the right and left wheels.

Checking and adjusting the angles of the front wheels is recommended to be carried out on a stand in a specialized workshop, however, the verification operation (except for checking the caster angle of the steering axis) can be performed with sufficient accuracy independently.

Attention! If the body was repaired after an accident or the suspension parts were changed, it is necessary to check the wheel alignment.

More accurate results are obtained by monitoring the angles on a laden car under a static load of 320 kgf, which approximately corresponds to the weight of four people placed on the seats and a load of 50 kg in the trunk. The fuel tank must be completely filled.

After the first maintenance and subsequent operation, the value of the angles must correspond to the following values:

|

- angle of longitudinal inclination of the axis of rotation |

4°+30' (3°+30') *; |

|

- camber angle |

0°30'+20' (0°5'+20') *; |

|

- wheel alignment |

2-4 (3-5) * mm. |

* in parentheses are the values of the angles on the car without load.

Before checking the wheel alignment angles, we check the air pressure in the tires, the absence of axial and radial runout of the tires, the play in the hub bearings, the play in the upper ball bearings of the suspension and the free wheeling of the steering wheel. If necessary, we eliminate the identified malfunctions. Before checking the angles, the steering wheel is set to the position of rectilinear movement. "We live" suspension of the car, applying 2-3 times a vertical force of 40-50 kgf, first to the rear bumper, and then to the front.

We check the wheel alignment in the following order:

- caster angle (check and adjustment only possible in a specialist workshop);

- camber angle (the test can be carried out by yourself, but the adjustment is possible only in a specialized workshop);

- convergence (You can check and adjust yourself).

Camber angle check

1. We prepare the car for operations (see "Vehicle preparation for maintenance and repair").

2. We carry out the preparatory work necessary before checking the wheel alignment (see above).

3. With a caliper we measure the distance from the plumb line to the upper and lower points of the rim and determine the difference in distances.

A difference of 3 mm corresponds approximately to a camber angle of 30'.

Convergence check

The convergence is regulated by changing the length of the steering rods by rotating their threaded couplings. This ensures the correct position of the front wheels of the car at different speeds and turning radii.

1. We prepare the car for operations (see "Vehicle preparation for maintenance and repair").

2. We carry out the preparatory work necessary before checking the wheel alignment (see above).

3. To do the work, we use a strong thread with wire hooks tied at the ends. We hook the hooks on the tread at the level of the axles of the rear and front wheels. Since the rear wheel track is smaller than the front wheel track at 44 mm, we put a bar 22 mm thick under the thread to the sidewall of each rear wheel.

4. We set the steering wheel in such a position that the thread touches the sidewall of the front wheel tire at diametrically opposite points.

5. We fix the thread on the protectors on the opposite side of the car and put a bar 6 mm thick under the thread on the sidewall of the rear wheel.

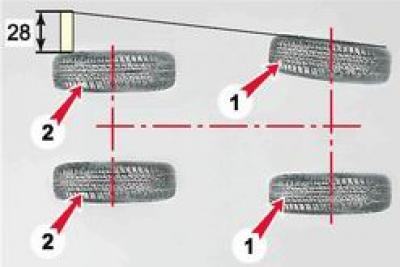

1 - front wheels; 2 - rear wheels

Thus, the total thickness of the bars on one side of the rear wheel will be 28 (22+6) mm. With a convergence of 1 mm for one front wheel, the thread should lightly touch the sidewall of its tire at diametrically opposite points.

Otherwise, adjust the wheel alignment.

For this:

A) Two keys by 13 mm Loosen the outer tie rod clamps.

b) With sliding pliers we rotate the clutch and adjust the length of the rod until the gaps between the thread and the sidewall of the front wheel tire disappear.

V) Tighten the clamps.

We carry out similar work with another wheel and achieve a total convergence of the front wheels of 2 mm.

To set the convergence of one wheel equal to 1.5 mm, it is necessary to place a bar with a thickness of 31 mm under the thread (22+9) mm, for convergence 2 mm - 34 (22+12) mm respectively.