Examination

You will need a multimeter to do the job.

1. Remove the generator from the car (see "Generator - removal and installation").

2. We clean the outer surface of the generator from dirt with a rag.

3. By connecting the positive probe of the ohmmeter to the output "30", and the negative probe to the generator housing, check for "breakdown" generator diodes.

If the ohmmeter shows a resistance close to zero, a breakdown of one or more diodes has occurred or the stator winding has shorted to the housing.

4. By connecting the positive probe of the ohmmeter to the output "30", and the negative one - to one of the bolts of the rectifier unit, we check the positive diodes.

If the ohmmeter shows a resistance close to zero, a breakdown of one or more diodes has occurred.

5. By connecting the positive probe of the ohmmeter to one of the rectifier unit mounting bolts, and the negative one to the generator housing, we check for "breakdown" generator negative diodes.

If the ohmmeter shows a resistance close to zero, a breakdown of one or more diodes has occurred.

6. By connecting one ohmmeter probe to the output "67" generator, and the other to the body, we check the reliability of the brushes to the slip rings and the absence of a short circuit in the excitation winding.

In the absence of short-circuited turns in the winding and tight fit of the brushes, the resistance should be in the range of 4.2-4.7 ohms at a temperature of 20°C.

7. Remove the brush holder (see below, "Repair"). When you press the brushes, they should move freely in the grooves, be spring-loaded. The protrusion of the brushes from the brush holder in the free state must be at least 5 mm, otherwise the brush holder must be replaced.

8. By connecting one probe of the ohmmeter to the housing, and the other to the slip ring of the rotor, we check the absence of a short circuit in the rotor winding to the generator housing.

If the ohmmeter shows a resistance close to zero, a short circuit has occurred.

A defective rotor, stator, capacitor or brush holder must be replaced. If one diode fails, we replace the rectifier assembly.

Repair

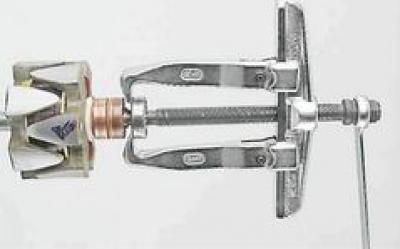

To perform the work, you will need: a two- or three-jaw puller, a mandrel for pressing out the front bearing, a mandrel for pressing in the rear bearing.

1. Holding the rotor from rotation with a screwdriver, with a socket wrench by 19 mm unscrew the nut securing the pulley and the impeller of the generator.

2. Remove the pulley parts, the generator cooling impeller, the segment key and restrictive washers from the shaft.

3. Using a Phillips screwdriver, unscrew the screw securing the brush holder.

4. We take out the brush holder from the generator housing.

5. socket wrench by 10 mm unscrew the four nuts securing the generator covers and remove the connecting bolts.

6. Leaning the front cover of the generator on a wooden block, with light blows on the shaft we press it from the stator.

7. Remove the generator cover and spacer.

8. Check the technical condition of the front bearing. While holding the cover, we shake and turn in both directions the inner ring of the bearing. The rotation of the bearing must be smooth, the axial play is negligible. We replace the defective bearing.

9. When replacing the front bearing with a socket wrench or ring wrench by 8 mm unscrew four nuts. If the nuts do not turn away, then we grind the pierced ends of the bolts.

Attention! After installing the bolts and tightening the nuts, the ends of the bolts must be punched out. If the length of the bolts is not enough for their punching, then the bolts are replaced.

10. We take out the bolts and remove the inner and outer bearing mounting washers.

11. With a mandrel suitable for the diameter, we press out the bearing.

12. Supporting the edges of the back cover of the generator (for example, two wooden blocks), knock out the rotor with a soft metal drift.

13. Check the technical condition of the rear bearing. The rotation of the bearing should be smooth, the axial play should be negligible. When the outer ring rotates quickly, there should not be much noise. We replace the defective bearing.

14. If it is necessary to replace the bearing, press it from the rotor shaft with a puller.

15. socket wrench by 8 mm with an extension cord, unscrew the three nuts securing the rectifier unit and the stator winding leads.

16. With a thin slotted screwdriver, we press the latch of the central output of the stator winding and push the output into the hole in the block.

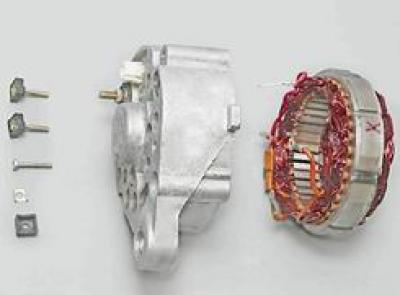

17. After removing the three bolts, remove the stator from the cover.

The insulation of the stator winding wires must be free from overheating.

18. socket wrench by 10 mm with a deep head unscrew the output nut "30" and remove the insulating washer A.

19. Remove the rectifier block.

Assembly

1. We clean the generator parts from dirt and dust, blow with compressed air, metal parts (except bearings) rinse with white spirit or kerosene.

2. With a mandrel that matches in diameter with the inner ring, lightly press the new bearing onto the rotor axis.

3. We check the mounting holes of the bearings in the covers. Holes should not be deformed, their surfaces should be free of burrs. If necessary, with a needle file or a scraper, we restore the chamfer of the edges of the holes. Replace cracked covers.

4. The misalignment of the holes in the ears of the generator covers should be no more than 0.4 mm. When assembling, for the mutual orientation of the covers, we use a mounting bolt and a buffer sleeve.

5. Assembly of the generator is carried out in reverse order.