Open large image in new tab »

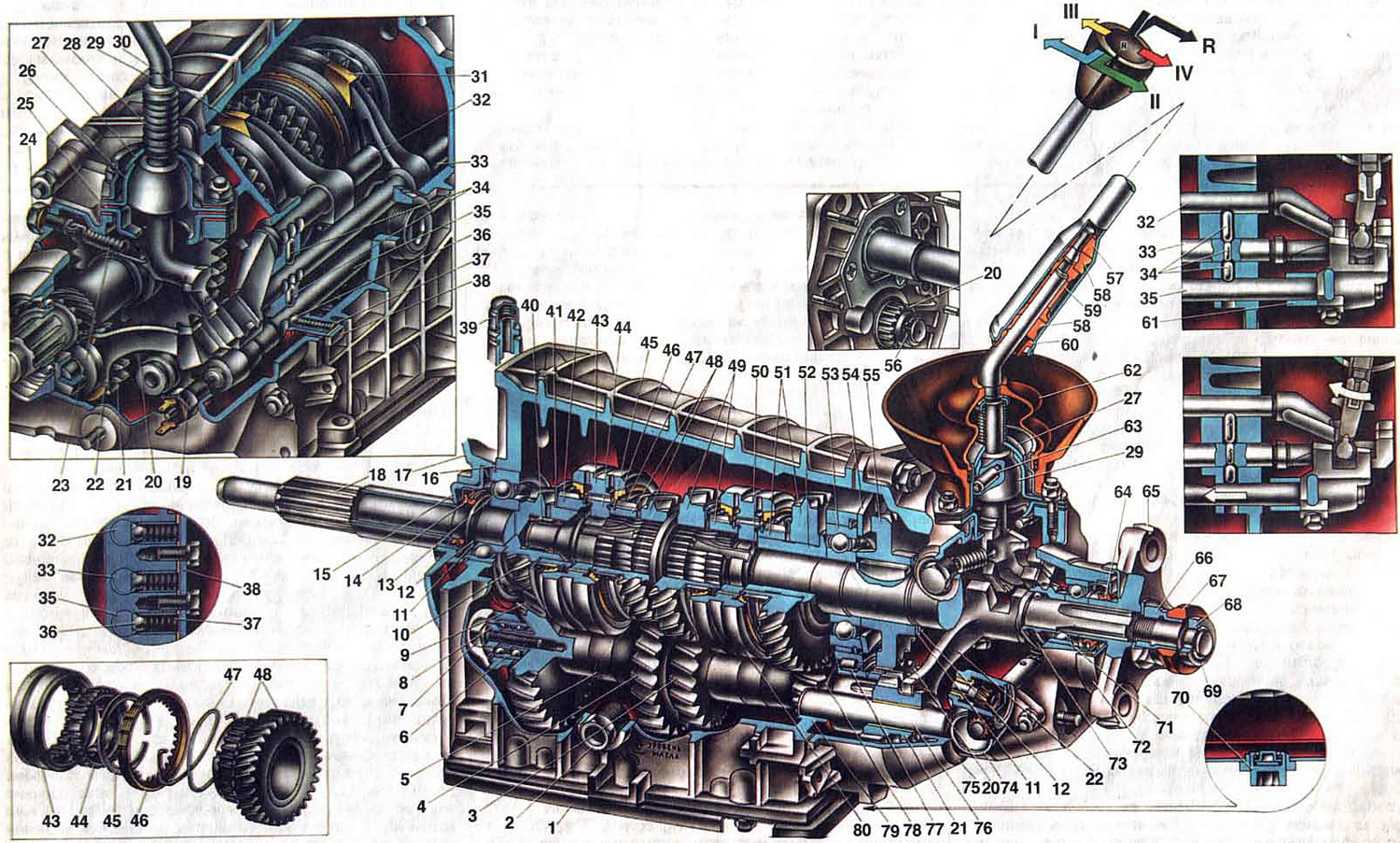

Pic. 15. Four-speed gearbox.

1. Bottom cover; 2. Filler and control plug; 3. Gear wheel of the second gear of the intermediate shaft; 4. Gear wheel of the third gear of the intermediate shaft; 5. Intermediate shaft; 6. Front intermediate shaft bearing; 7. Bolt washer; 8. Clamping washer of the front bearing of the intermediate shaft; 9. Pinion of constant meshing of the intermediate shaft; 10. Gear wheel of constant engagement of the input shaft; 11. Spring washer; 12. Retaining ring; 13. Rear bearing input shaft; 14. Primary shaft seal; 15. Gearbox front cover; 16. Bearing adjusting ring; 17. Clutch housing; 18. Gearbox drive shaft; 19. The switch of a lantern of a backing; 20. Countershaft reverse gear; 21. Intermediate reverse gear; 22. Reverse fork; 23. Retractable spring of the gear lever; 24. Retracting spring bolt; 25. Gear lever guide cup; 26. Ball joint lever; 27. Spherical washer; 28. Spring; 29. Gearshift lever; 30. Fork of inclusion of I and II transfers; 31. Fork of inclusion of III and IV transfers; 32. The rod of the fork of inclusion of I and II gears; 33. The rod of the fork of inclusion of III and IV gears; 34. Block crackers; 35. Reverse fork rod; 36. Ball retainer rod; 37. Detent spring; 38. Latch cover; 39. Breather; 40. Needle bearing of the front end of the driven shaft; 41. Thrust washer of the synchronizer spring; 42. Gear rim synchronizer IV gear; 43. Sliding clutch synchronizer III and IV gears; 44. The hub of the sliding clutch of the synchronizer of III and IV gears; 45. Synchronizer retaining ring; 46. Blocking ring synchronizer; 47. Synchronizer spring; 48. Gear and ring gear synchronizer III gear; 49. Gear and ring gear synchronizer II gear; 50. Secondary shaft; 51. Gear and ring gear of the synchronizer of the 1st gear; 52. Bushing gear 1st gear; 53. Intermediate bearing of the secondary shaft; 54. Intermediate bearing lock plate; 55. Reverse gear of the secondary shaft; 56. A lock ring of a gear wheel of a backing of an intermediate shaft; 57. Elastic pillow of a damper of the gear lever; 58. Rubber damper bushing; 59. Damper spacer; 60. Locking sleeve damper; 61. Stem spacer; 62. The inner cover of the gear lever; 63. Lever guide pin; 64. Seal of the rear bearing of the secondary shaft; 65. Flange of the flexible coupling of the cardan shaft; 66. Nut; 67. Centering ring seal; 68. Centering ring; 69. Retaining ring; 70. Rear output shaft bearing; 71. Drain plug; 72. Dirt deflector; 73. Speedometer drive gear; 74. Speedometer drive; 75. Rear cover of the gearbox; 76. The axis of the intermediate reverse gear; 77. Rear intermediate shaft bearing; 78. Gear wheel of the 1st gear of the intermediate shaft; 79. Gearbox housing; 80. Sliding clutch synchronizer I and II gears.

1. Bottom cover; 2. Filler and control plug; 3. Gear wheel of the second gear of the intermediate shaft; 4. Gear wheel of the third gear of the intermediate shaft; 5. Intermediate shaft; 6. Front intermediate shaft bearing; 7. Bolt washer; 8. Clamping washer of the front bearing of the intermediate shaft; 9. Pinion of constant meshing of the intermediate shaft; 10. Gear wheel of constant engagement of the input shaft; 11. Spring washer; 12. Retaining ring; 13. Rear bearing input shaft; 14. Primary shaft seal; 15. Gearbox front cover; 16. Bearing adjusting ring; 17. Clutch housing; 18. Gearbox drive shaft; 19. The switch of a lantern of a backing; 20. Countershaft reverse gear; 21. Intermediate reverse gear; 22. Reverse fork; 23. Retractable spring of the gear lever; 24. Retracting spring bolt; 25. Gear lever guide cup; 26. Ball joint lever; 27. Spherical washer; 28. Spring; 29. Gearshift lever; 30. Fork of inclusion of I and II transfers; 31. Fork of inclusion of III and IV transfers; 32. The rod of the fork of inclusion of I and II gears; 33. The rod of the fork of inclusion of III and IV gears; 34. Block crackers; 35. Reverse fork rod; 36. Ball retainer rod; 37. Detent spring; 38. Latch cover; 39. Breather; 40. Needle bearing of the front end of the driven shaft; 41. Thrust washer of the synchronizer spring; 42. Gear rim synchronizer IV gear; 43. Sliding clutch synchronizer III and IV gears; 44. The hub of the sliding clutch of the synchronizer of III and IV gears; 45. Synchronizer retaining ring; 46. Blocking ring synchronizer; 47. Synchronizer spring; 48. Gear and ring gear synchronizer III gear; 49. Gear and ring gear synchronizer II gear; 50. Secondary shaft; 51. Gear and ring gear of the synchronizer of the 1st gear; 52. Bushing gear 1st gear; 53. Intermediate bearing of the secondary shaft; 54. Intermediate bearing lock plate; 55. Reverse gear of the secondary shaft; 56. A lock ring of a gear wheel of a backing of an intermediate shaft; 57. Elastic pillow of a damper of the gear lever; 58. Rubber damper bushing; 59. Damper spacer; 60. Locking sleeve damper; 61. Stem spacer; 62. The inner cover of the gear lever; 63. Lever guide pin; 64. Seal of the rear bearing of the secondary shaft; 65. Flange of the flexible coupling of the cardan shaft; 66. Nut; 67. Centering ring seal; 68. Centering ring; 69. Retaining ring; 70. Rear output shaft bearing; 71. Drain plug; 72. Dirt deflector; 73. Speedometer drive gear; 74. Speedometer drive; 75. Rear cover of the gearbox; 76. The axis of the intermediate reverse gear; 77. Rear intermediate shaft bearing; 78. Gear wheel of the 1st gear of the intermediate shaft; 79. Gearbox housing; 80. Sliding clutch synchronizer I and II gears.

The gearbox is four-speed. All its parts are located in two basic parts: in the crankcase 79 and the back cover 75. The crankcase has an input shaft 18, a secondary shaft 50 complete with gears and synchronizers and an intermediate shaft 5. The input shaft rotates in two bearings, the front one is located at the end of the crankshaft shaft, rear bearing 13 - in the socket of the front wall of the crankcase. Its setting ring is sandwiched between the clutch and gearbox housings. On the shaft, the bearing is clamped between the shoulder of the shaft and the spring washer 11, which is locked on the shaft with a retaining ring 12. With this fixation of the bearing in the seat and on the shaft, axial displacement of the shaft is excluded.

The input shaft is made together with the helical gear rim 10, which is in constant engagement with the gear 9 of the intermediate shaft. From the end of the shaft, a spur rim 42 of the IV gear synchronizer is pressed onto the machined belt, and then soldered with copper. In the same end of the shaft, a socket is machined for the needle bearing 40 of the secondary shaft. The clutch disc is located on the splines of the shaft.

The secondary shaft 50 is, as it were, a continuation of the primary shaft. It rests on three bearings. The needle bearing 40 is located at the end of the input shaft, the intermediate 53 is located in the rear wall of the crankcase, and the rear double-row bearing 70 is located in the socket of the rear gearbox cover. The intermediate bearing is kept from moving in the socket by a set ring and a locking plate 54, which is attached to the crankcase wall with screws. On the shaft, the bearing is clamped between the sleeve 52 and the reverse gear 55 under the force of the spring washer 11, which is held on the shaft by the retaining ring 12. The rear bearing 70 is clamped by the nut 66 between the gear 73 of the speedometer drive and the flange 65 of the elastic coupling. The nut is locked by a washer that is bent onto the face of the nut. At the outlet of the cover, the secondary shaft is sealed with an oil seal, the working edge of which is adjacent to the polished surface of the flange 65. The oil seal is protected by a dirt deflector 72. A rubber seal 67 is tightly fitted onto the cylindrical belt of the nut, then a centering ring 68 is pressed onto the end of the shaft and a retaining ring 69 is installed. gears 48 and 49 of III and II gears rotate on the necks of the secondary shaft. Gear 51 I transmission rotates on a steel heat-treated sleeve 52, clamped on the shaft between the bearing 53 and the synchronizer hub. These gears have two crowns. The helical rims are in constant engagement with the gears of the same name of the intermediate shaft, and the clutches 43 and 80 of the synchronizers are connected to the spur rims when the 1st, 2nd or 3rd gears are engaged. On the two belts of the secondary shaft, three deep grooves are made, into which the protrusions of the hubs of the synchronizer couplings enter. The hub 44 of the synchronizer of III and IV gears is pressed against the shoulder of the shaft by a spring washer and is locked on the shaft by a ring. The other hub is sandwiched between bushing 52 and the shoulder of the shaft. From axial displacement, it is held together with the intermediate bearing 53 and gear 55 by a spring washer 11 and a retaining ring 12. The reverse gear 55 is connected to the shaft with a key.

Synchronizer - inertial type, provides bumpless gear shifting. The design of both synchronizers is the same. The synchronizer of III and IV gears consists of a hub 44, a sliding clutch 43, two blocking rings 46, springs 47, circlips 45 and synchronizer rims of the input shaft and gear 48 of the III gear.

The intermediate shaft 5 is made in the form of a block of four gears. The shaft rotates in a double-row ball bearing 6 and a cylindrical roller bearing 77. The bearing is mounted on the shaft with a bolt 7 through spring and flat washers. The roller bearing is clamped on the shaft between the shoulder of the shaft and the reverse gear 20. This gear is mounted on the splines of the shaft and is held on them by a retaining ring.

The intermediate gear 21 reverse is located on the axle 76 on a ceramic-metal bushing. The axle is installed in the holes of the crankcase wall and the tide of the gearbox rear cover and is locked by plate 54.

Engaging and shifting gears is carried out through a mechanical drive, consisting of a lever 29, three rods with forks, latches and a locking device. The shift lever is split to facilitate the removal and installation of the gearbox on the vehicle. The lever stem is connected to the lever itself via elastic damper bushings that absorb vibrations and provide smoother gear shifting. The gear lever is mounted in the rear cover 75. The guide cup 25 of the lever, the ball bearing 26 and the flange of the sealing boot 62 are attached to the cover on three studs with nuts and spring washers. Gaskets are installed between them. The lever 29 has a support ball, which is pressed by the spring 28 to the surface of the ball bearing. The same spring presses the spherical washer 27 from above to the ball bearing. To prevent the lever hinge from turning in the ball bearing, a pin 63 is pressed into the bearing ball, the end of which enters the support hole. The ball joint is protected by a rubber cover 62, and the exit point of the lever into the car interior is sealed from below with a cuff.

The movement of the synchronizer couplings and the reverse intermediate gear is carried out by forks, which are bolted to the rods. The rod 33 of the fork of inclusion of III and IV gears is installed in the holes of the front and rear walls of the crankcase, and the rods 32 and 35 are in the holes of the rear wall and the tide of the crankcase. In the neutral and engaged positions, the rods are held by ball retainers, which are pressed against the sockets of the rods by springs 37. The retainers are closed with a common cover 38. To prevent the simultaneous activation of two gears, the drive has a locking device consisting of three blocking crackers 34. Two extreme crackers of a larger diameter are installed in the hole of the rear wall, and the middle one - in the hole of the rod 33.